Preparation and application for trans fat-free pastry oil

A zero-trans, fatty acid technology, applied in the field of preparation and application of zero-trans fatty acid puff pastry oil, can solve the problems of single modification method, puff pastry oil hardness needs to be improved, etc., to achieve uniform product texture and facilitate industrial operation , the effect of improving the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Chemical interesterification of lard and palm stearin

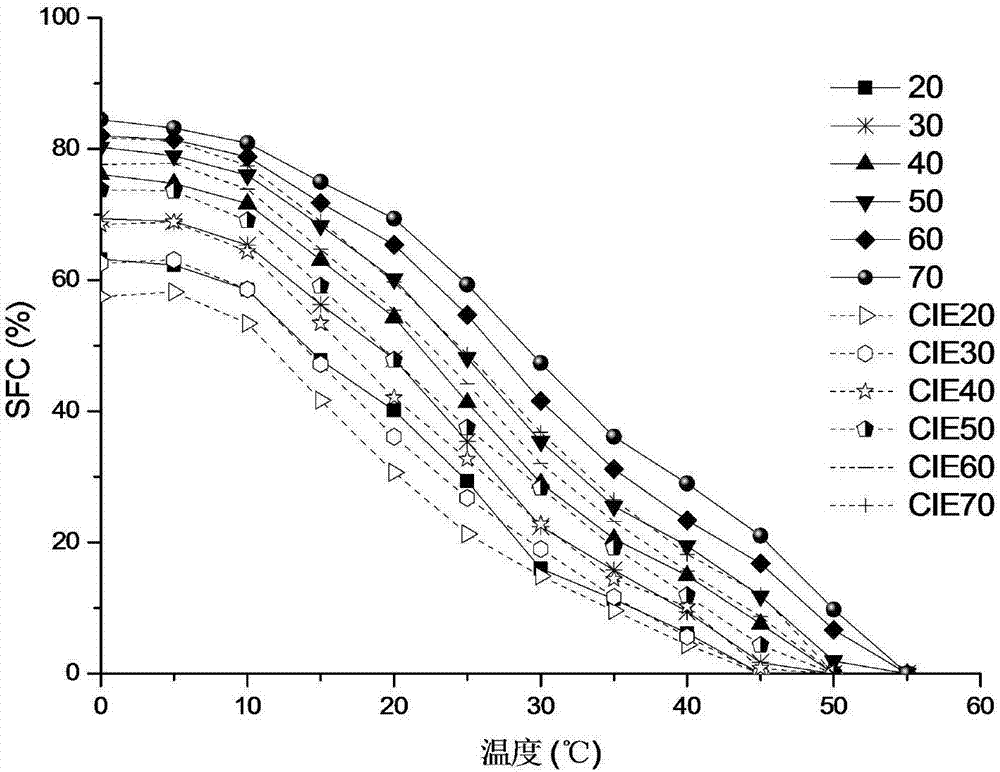

[0034] Accurately weigh 100g of a mixture of lard and palm stearin containing 20%, 30%, 40%, 50%, 60%, and 70% of palm stearin, put them in an enzyme reactor, and dry them under vacuum at 0.1MPa at 90°C After 30 minutes, add 0.4% sodium methoxide after thermal equilibrium at 60°C, carry out 30 minutes under continuous stirring and vacuum conditions, stop the reaction of the sample with 5% citric acid solution, wash with hot water to remove excess citric acid and sodium methoxide, and vacuum dry to remove After adding water, heat at 90°C for 20 minutes, add 1.5% decolorized clay to remove impurities, and centrifuge to obtain the transesterified product. Measure the SFC value of solid fat content before and after chemical transesterification, and obtain the change curve of solid fat content with temperature figure 1 Among them, the SFC before transesterification shows a sharp drop in the temperature range...

Embodiment 2

[0035] Example 2: Enzymatic transesterification of lard and palm stearin

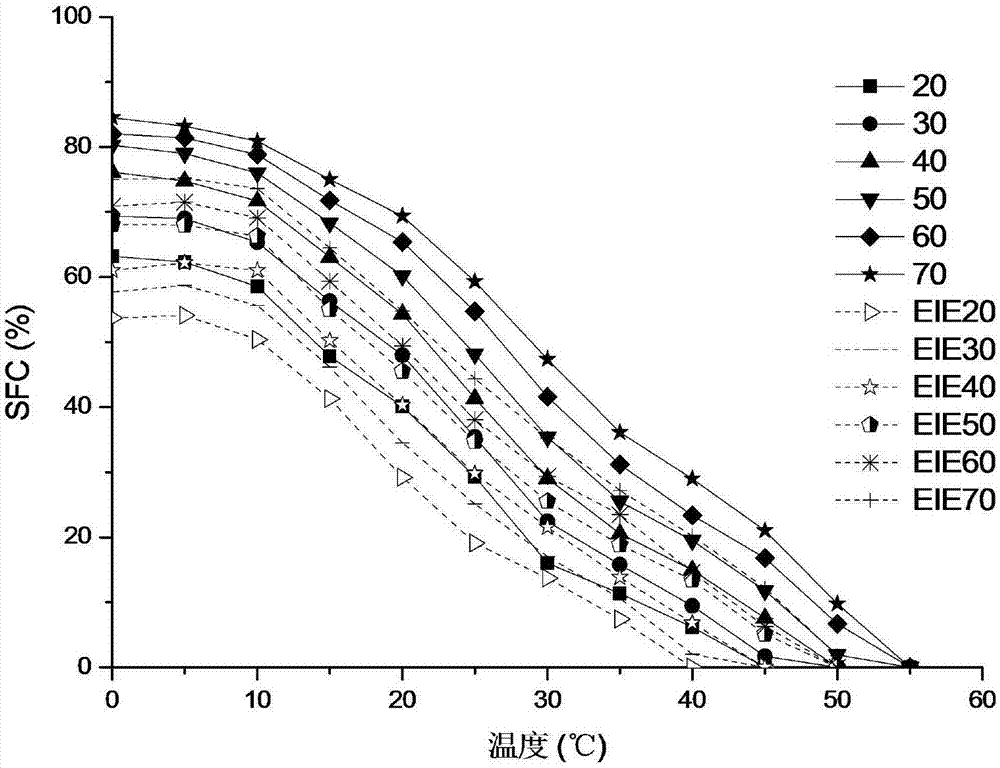

[0036] Accurately weigh 100g of the mixture of lard and palm stearin containing 20%, 30%, 40%, 50%, 60%, and 70% of palm stearin in the enzyme reactor at a speed of 50-80r / min Stirring, vacuum dehydration and degassing, equilibrium temperature to 60°C, then adding 8% immobilized lipase Lipozyme TL IM, after reaction for 1h, suction filtration to remove the immobilized lipase to obtain the transesterification product. Taking the change of the solid fat content (SFC) of the product at 20°C as an index, measure the SFC value of the solid fat content before and after enzymatic transesterification, and obtain the change curve of the solid fat content with temperature figure 2 , where the SFC before transesterification showed a sharp drop in the temperature range of 15-30°C, and the plasticity range was narrow, while the curve after enzymatic transesterification decreased more gently, and it was not easy to ...

Embodiment 3

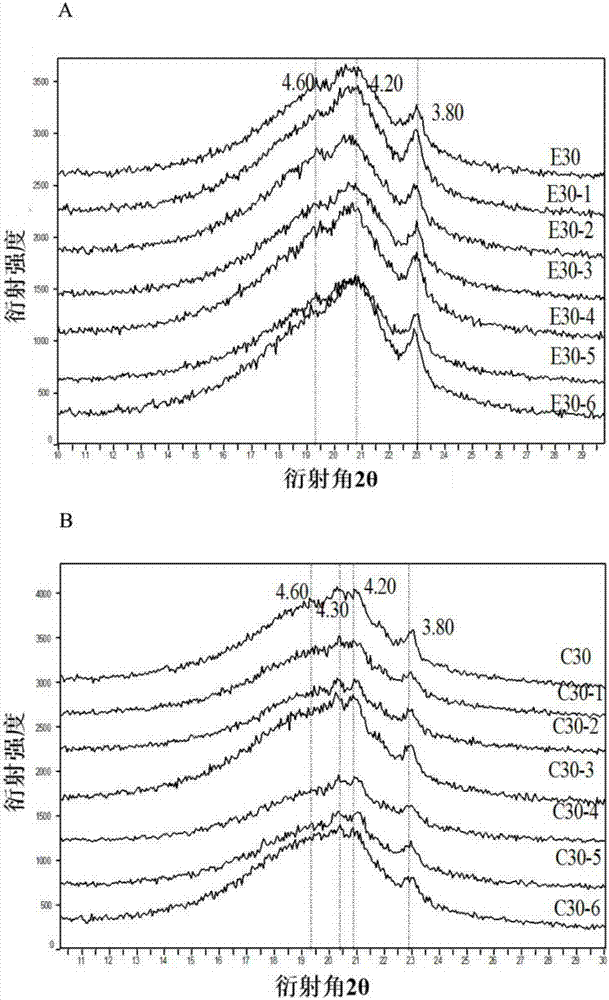

[0037]Embodiment 3: crystal form analysis

[0038] Take the chemical method interesterification oil and the enzymatic method interesterification oil with palm stearin content of 30%, respectively, add six different emulsifiers after melting at 70°C, add water slowly under stirring, the ratio is 83:1:16, After stirring in a water bath at 65°C for 30 minutes, then immerse the emulsion in the cooling liquid of ethanol ice cubes, shake and cool for 5 minutes, place it in a 20°C thermostat for 24 hours, and then conduct XRD analysis. Measured with an X-ray diffraction scanner. The condition is copper target Cu-Kα (λ=0.15406nm), the power is 1600W (40kV×40mA), the intensity of X-ray is measured by NaI crystal scintillation counter (scintillation counter), the scanning range is 3°-30°, and the scanning speed is 4 ° / min, step size 0.02°. The settings of DS-SS-RS are 1mm-1mm-0.1mm [divergence slit (abbreviated as DS), anti-scattering slit (abbreviated as SS), receiving slit (abbrevia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com