Method for preparing zinc oxide electronic film at low temperature

A technology of electronic thin film and zinc oxide, which is applied in the direction of liquid chemical plating, metal material coating technology, coating, etc., can solve the problems of difficult to realize large-scale film formation, strong toxicity of diethyl zinc, easy fire and explosion, etc. Achieve the effect of improving photoelectric conversion efficiency, low cost and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing ZnO electronic thin film by low-temperature spray pyrolysis, the steps are as follows:

[0037] (1) Precursor preparation

[0038] Dissolve 11g of zinc acetate in deionized water to form a 1mol / L zinc acetate solution, put it in a beaker, and under the action of magnetic force or electric stirring, add concentrated ammonia water dropwise to control the pH of the solution to 8, Zn 2+ Gradually converted to Zn(OH) 2 Precipitation, vacuum filtration, while suction filtration was repeatedly washed with a large amount of deionized water to remove excess anions (CH 3 COO - , NO 3 - , Cl - and other impurities), dry, weigh 5g of precipitate, add 30ml of deionized water and 10ml of methanol, add 10ml of ammonia water, dissolve the precipitate, and form a pH of 11, [(Zn(NH 3 ) 4 ] 2+ A transparent ammonium zinc solution with a concentration of 0.1mol / L was used as a precursor.

[0039] (2) Thin film deposition

[0040] Put the glass fiber reinfor...

Embodiment 2

[0045] A method for preparing ZnO electronic thin film by low temperature spray pyrolysis, same as embodiment 1, wherein:

[0046] In step (1), zinc nitrate is used as the raw material for the preparation of the precursor solution, and 25ml of deionized water and 15ml of methanol are added to the precipitate.

[0047] In step (2), the heating temperature of the substrate is 150°C.

[0048] In step (3), the prepared ZnO thin film and substrate are heated to 250° C., kept for 2 hours, and then cooled naturally.

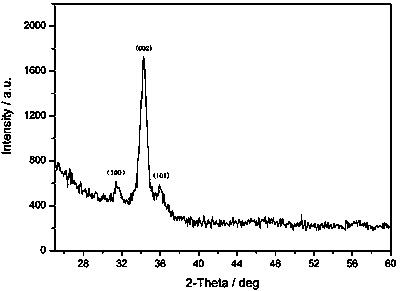

[0049] The prepared ZnO thin film: the average transmittance in the visible light range reaches more than 85%, the surface roughness is less than 10nm, and does not contain residual solvents, the impurity content is less than 1%, the C axis is preferentially oriented, and the average particle size of the microscopic particles is about 10nm ~20nm, good uniformity.

Embodiment 3

[0051] A method for preparing ZnO electronic thin film by low temperature spray pyrolysis, same as embodiment 1, wherein:

[0052] In step (2), adjust the distance between the nozzle and the substrate to 200mm, take 30ml of the precursor solution into the conical flask, connect the peristaltic pump to the nozzle, control the flow rate of the precursor solution to 0.5ml / min, and adjust the air pressure through the pressure regulating valve. The control is 2atm, and the deposition time is 30min.

[0053] The prepared ZnO thin film: the average transmittance in the visible light range reaches more than 85%, the surface roughness is less than 10nm, and does not contain residual solvents, the impurity content is less than 1%, the C axis is preferentially oriented, and the average particle size of the microscopic particles is about 10nm ~20nm, good uniformity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com