Method for improving frost resistance of edible fat

A technology of edible oil and antifreeze, which is applied in the fields of edible oil/fat, application, food science, etc. It can solve the problems of non-fractionation treatment and poor frost resistance, so as to improve the effect of fractionation and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

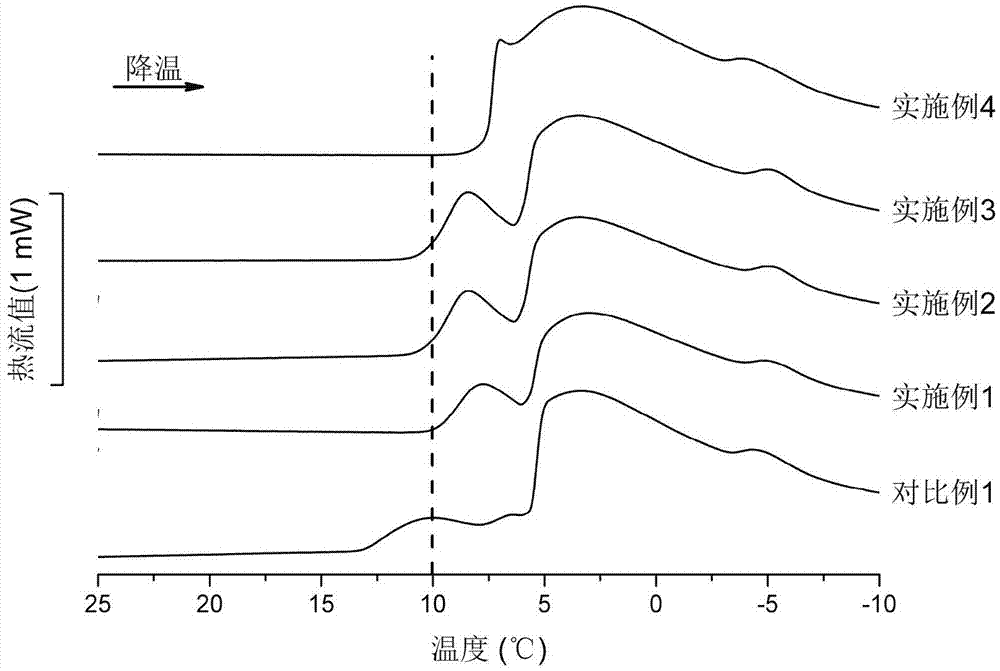

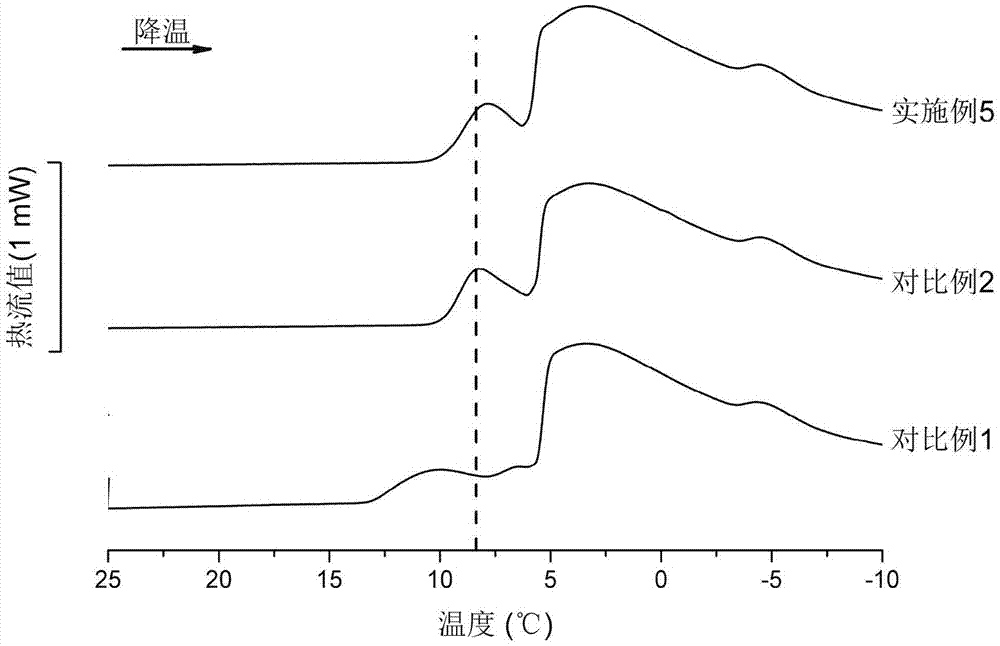

Embodiment 1

[0061] Decolorized palm olein is carried out to deodorization and refining: add 0.05% citric acid (mass fraction, add with the solution form that mass concentration is 20%, the same below) to decolorized palm olein and mix well, pass into nitrogen (serve as stirring and deodorization medium), the vacuum degree is about 10-20mBar, heated to 250°C and kept for 90 minutes, then removed the heating jacket, and when the temperature dropped below 50°C, the vacuum was broken and nitrogen gas was stopped to obtain secondary refined palm olein.

Embodiment 2

[0063] Deodorize and refine the decolorized palm olein: add 0.2% citric acid to the decolorized palm olein and pass nitrogen gas to make it evenly mixed, the vacuum degree is about 10-20mBar, heat to 250°C and keep it for 90 minutes, then remove the heating jacket , when the temperature drops below 50°C, the vacuum is broken and nitrogen gas is stopped to obtain secondary refined palm olein.

Embodiment 3

[0065] Deodorize and refine the decolorized palm olein: add 0.2% citric acid to the decolorized palm olein and pass nitrogen gas to make it evenly mixed, the vacuum degree is about 10-20mBar, heat to 270°C and keep it for 90 minutes, then remove the heating jacket , when the temperature drops below 50°C, the vacuum is broken and nitrogen gas is stopped to obtain secondary refined palm olein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com