Fruit wine distillation equipment and method using secondary steam purification and packing fractionation

A secondary steam and steam technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of turbidity and loss of luster in the appearance of fruit wine, affecting product quality, and excessive methanol content, so as to avoid the appearance of turbidity and luster, avoid iron ion pollution, The effect of improving the wine yield of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

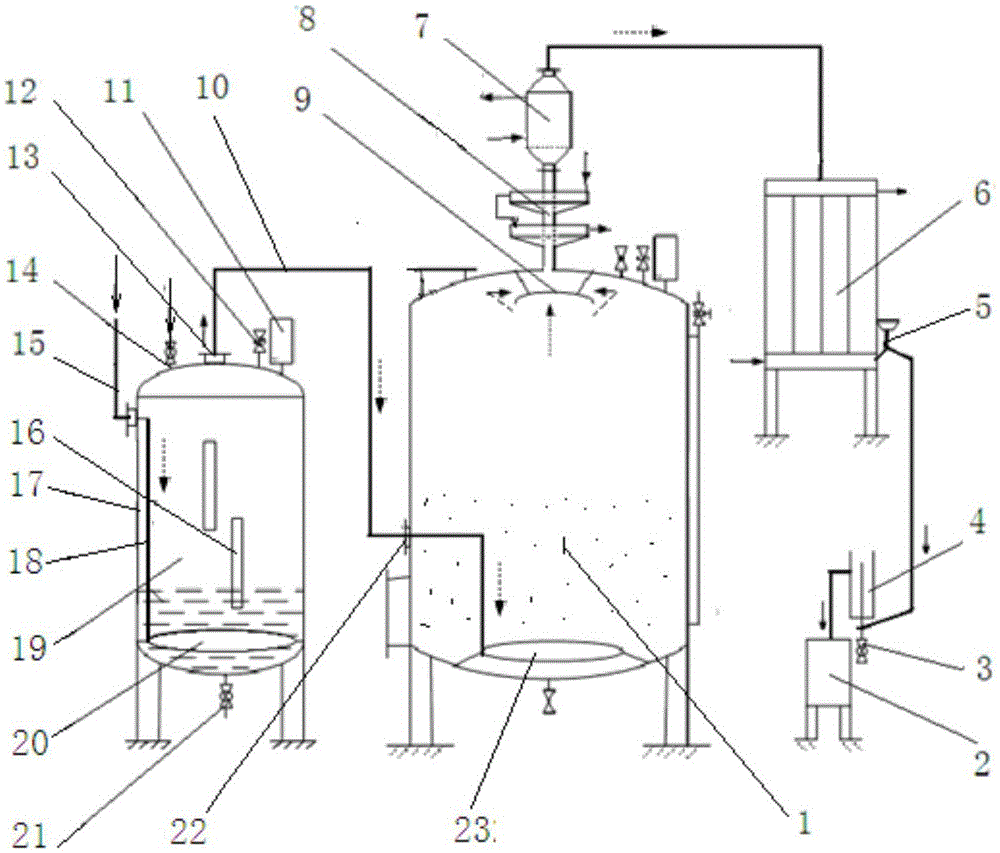

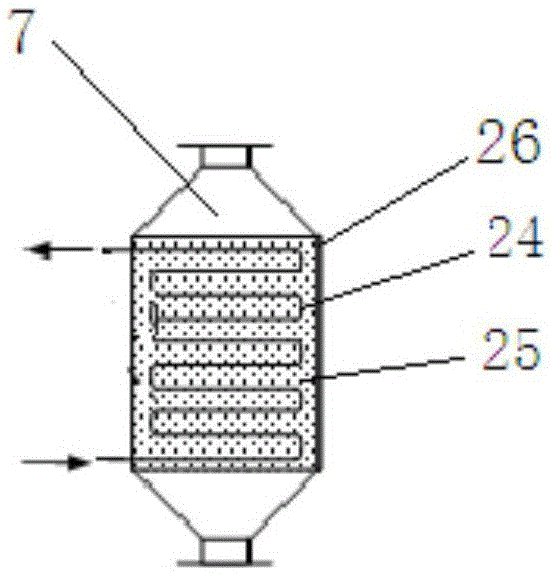

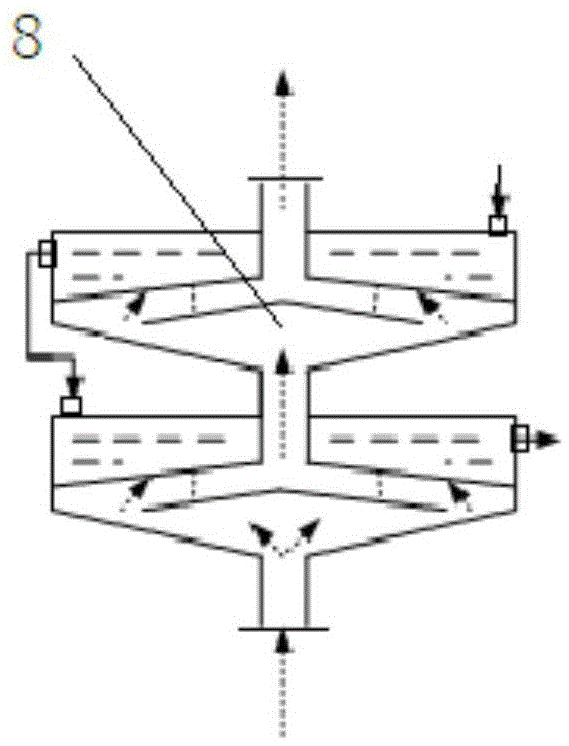

[0039] Such as figure 1 Shown, a kind of fruit wine distillation equipment of secondary steam purification, filler fractionation, technical scheme is: it comprises a secondary steam generator 19 and a batch type distillation tank 1, and batch type distillation tank 1 top is provided with two vertical External cooling umbrella fractionator 8 in direct series (see image 3 ), the alcohol vapor outlet of the external cooling umbrella fractionator 8 is connected with a water circulation cooling packing tank 7, and the alcohol vapor outlet of the water circulation cooling packing tank 7 is connected with the jacket cooler 6 alcohol vapor inlets, and the jacket cooler 6 The wine outlet is provided with a vertical methanol discharge pipe 5; the bottom of the methanol discharge pipe 5 is provided with an overflow wine dispenser 4, and the bottom of the overflow wine dispenser 4 is provided with a head wine valve 3, and the overflow wine dispenser The top of 4 is connected with wine b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com