Oil storage barrel

A technology for oil storage barrels and oil barrels, applied in the field of oil storage containers, can solve problems such as oil oxidation and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

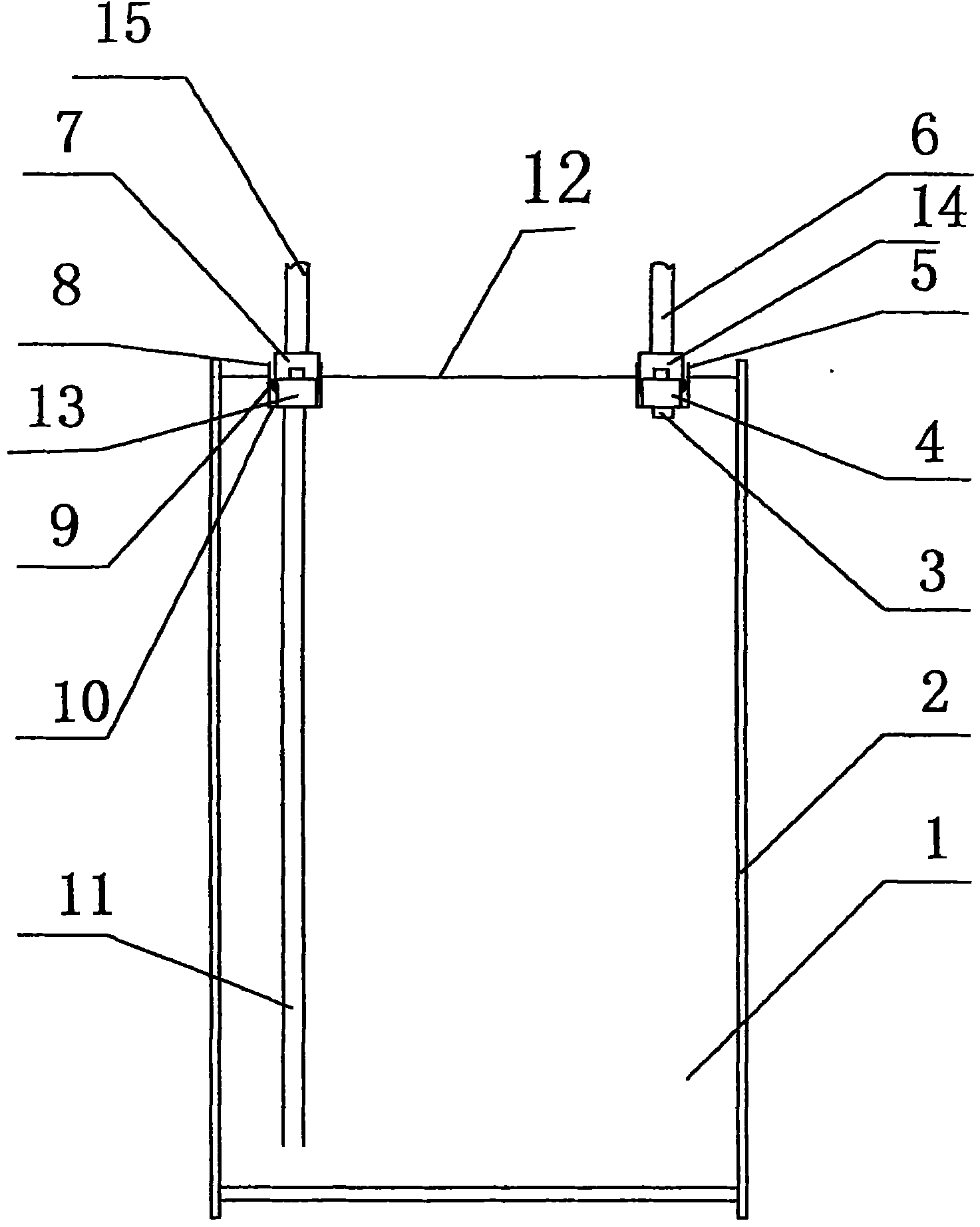

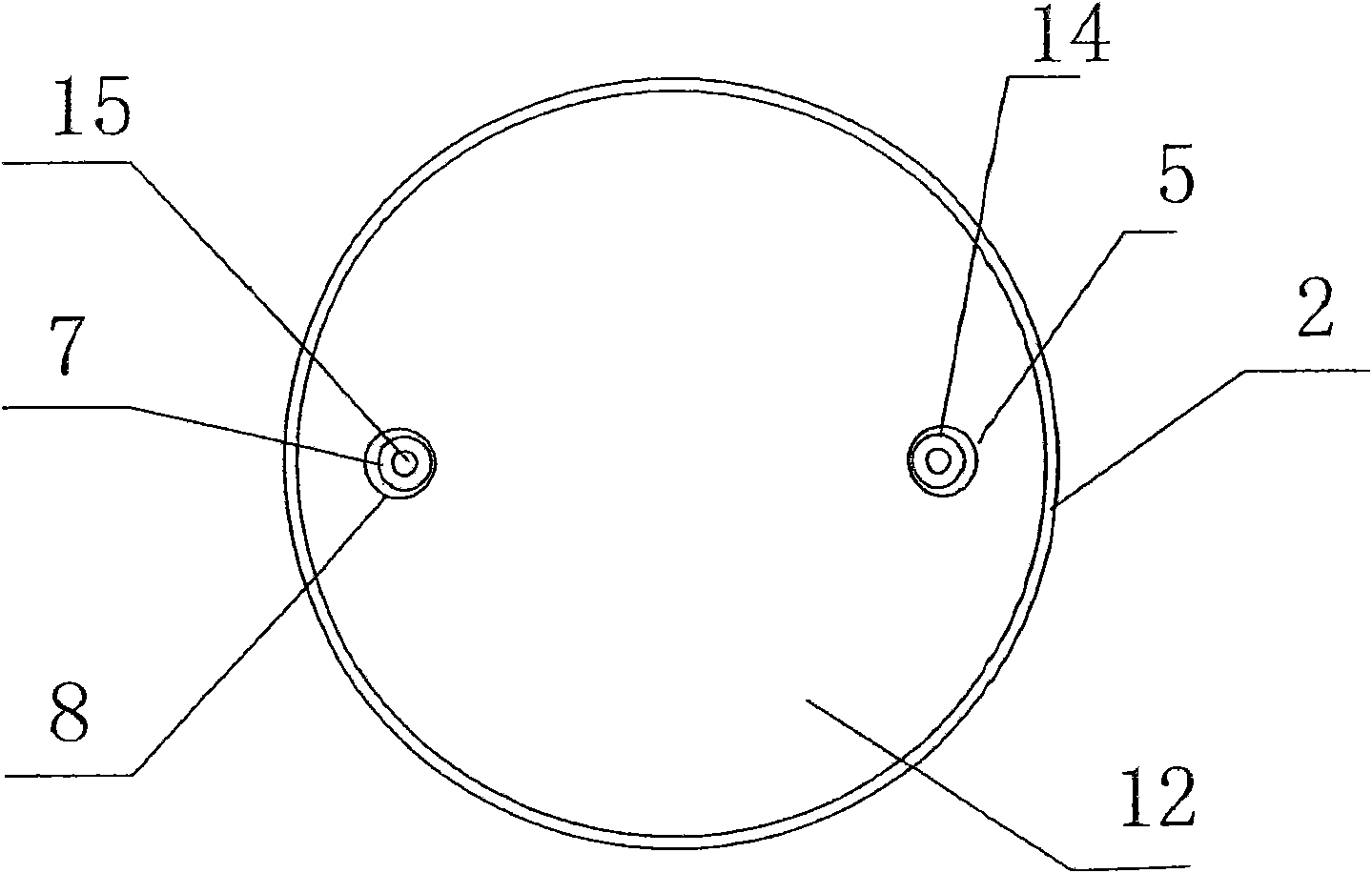

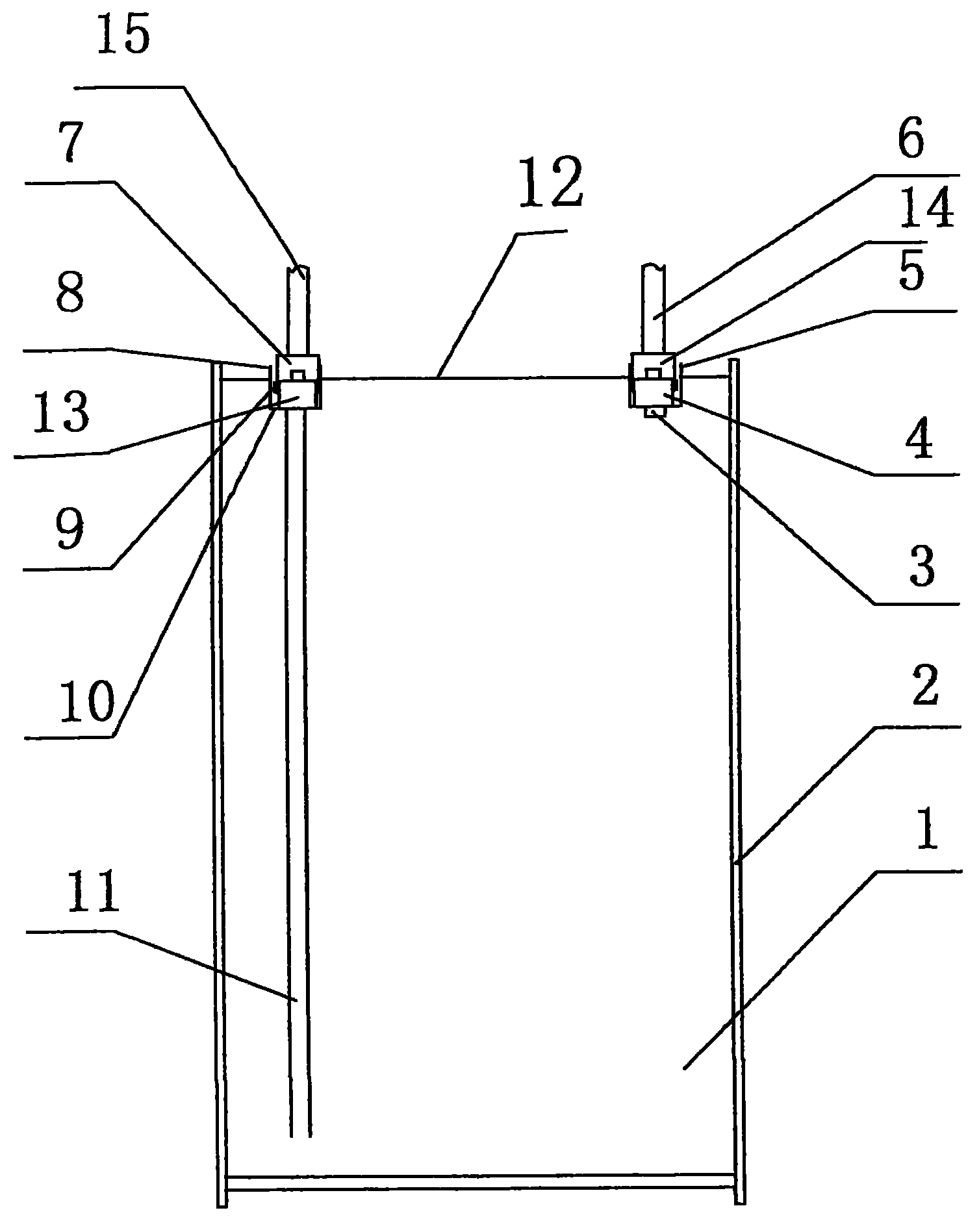

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0014] Such as figure 1 , figure 2 As shown, two oil-taking through holes are arranged on the top cover surface 12 of the barrel body 1, which are symmetrically distributed on both sides of the cover surface 12. The connection is fixed, and the upper and lower edges of the barrel wall 2 of the oil storage barrel are slightly higher than the cover surfaces of the top and bottom respectively, forming a certain height difference to facilitate the stacking and transportation of the oil storage barrels.

[0015] The oil drum covers 5, 8 are composed of two parts, the outer structure of the cylinder 10 with a concave cavity and the inner CPC joint, wherein the CPC joint is composed of inner joints 4, 13 and outer joints 7, 14, which are switched through joints 9 are detachably plugged and connected. The cylinders 10 of the oil drum covers 5, 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com