Valve with adjustable opening and closing frequency

An adjustable and frequency technology, applied in the field of regulating valve, can solve the problem of low spool moving speed when the spool is opened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

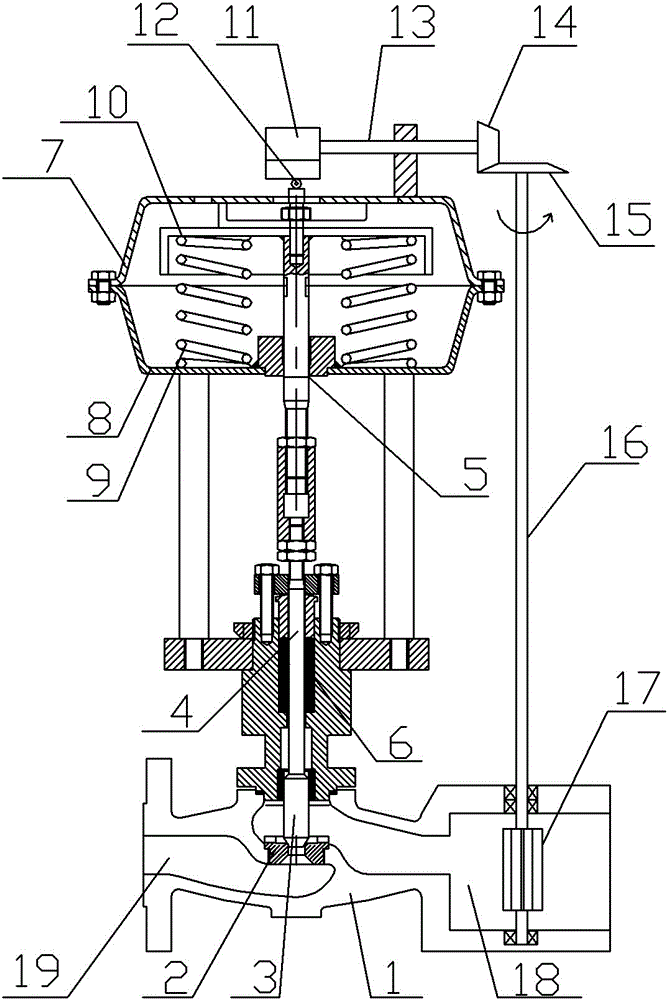

[0014] The reference signs in the drawings of the specification include: valve body 1, valve seat 2, valve core 3, valve stem 4, actuator rod 5, sealing stuffing box 6, upper cover 7, lower cover 8, return spring 9, pressure plate 10 , Cam 11, roller 12, cross bar 13, bevel gear 14, bevel gear 15, rotating shaft 16, impeller 17, water inlet cavity 18, water outlet cavity 19.

[0015] Embodiment The valve with adjustable opening and closing frequency is basically as attached figure 1 Shown:

[0016] The valve with adjustable opening and closing frequency is divided into three parts: feedback mechanism, actuator and valve body 1 from top to bottom.

[0017] A water inlet chamber 18 and a water outlet chamber 19 are arranged in the valve body, and the water inlet chamber 18 and the water outlet chamber 19 are communicated through the valve port, and the water flow flows fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com