Device and method for comprehensively utilizing construction waste

A construction waste and directly below technology, which is applied in the field of comprehensive utilization of construction waste devices, can solve the problems of time-consuming, labor-intensive, low recycling efficiency, etc., and achieve the effect of ensuring normal power on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

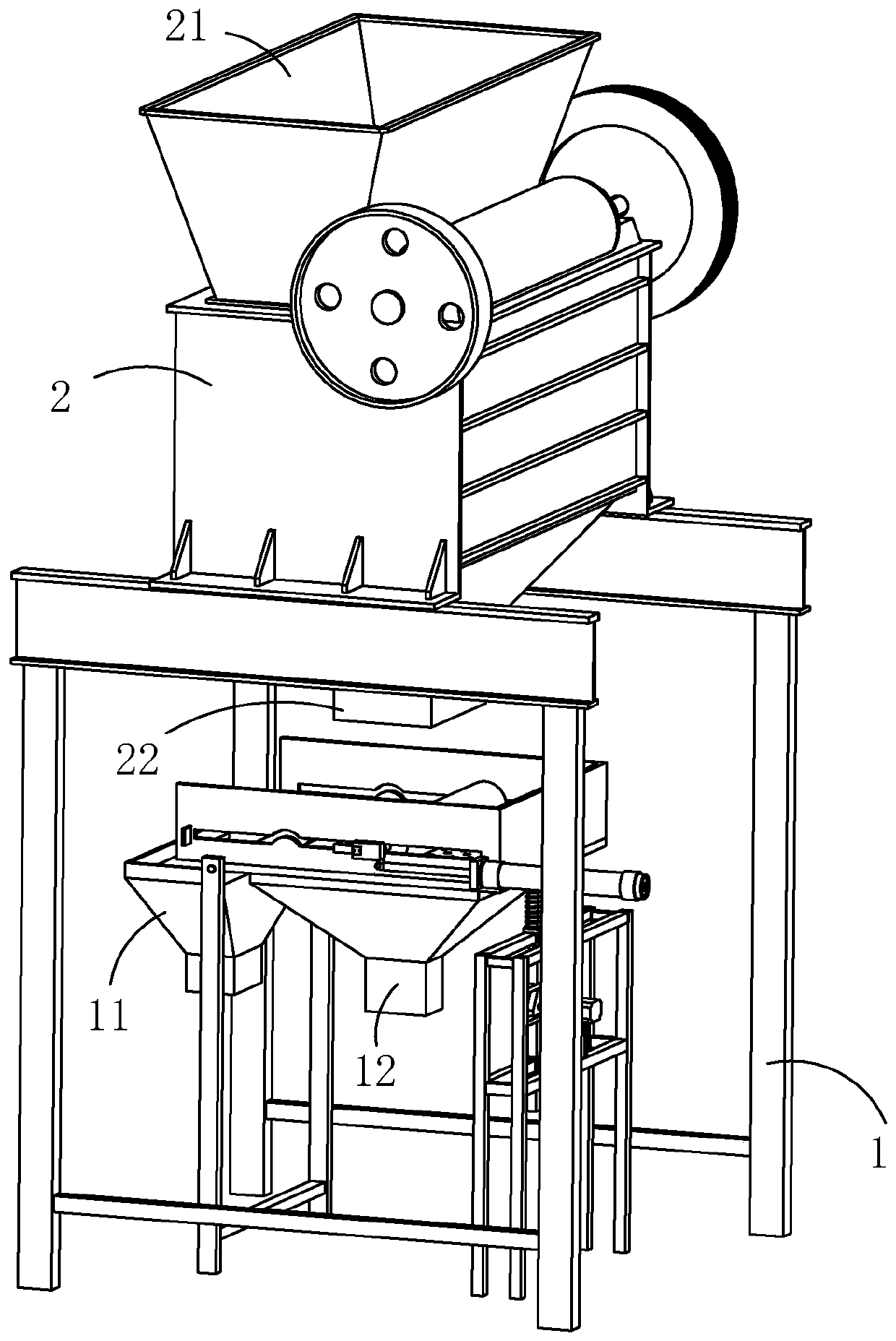

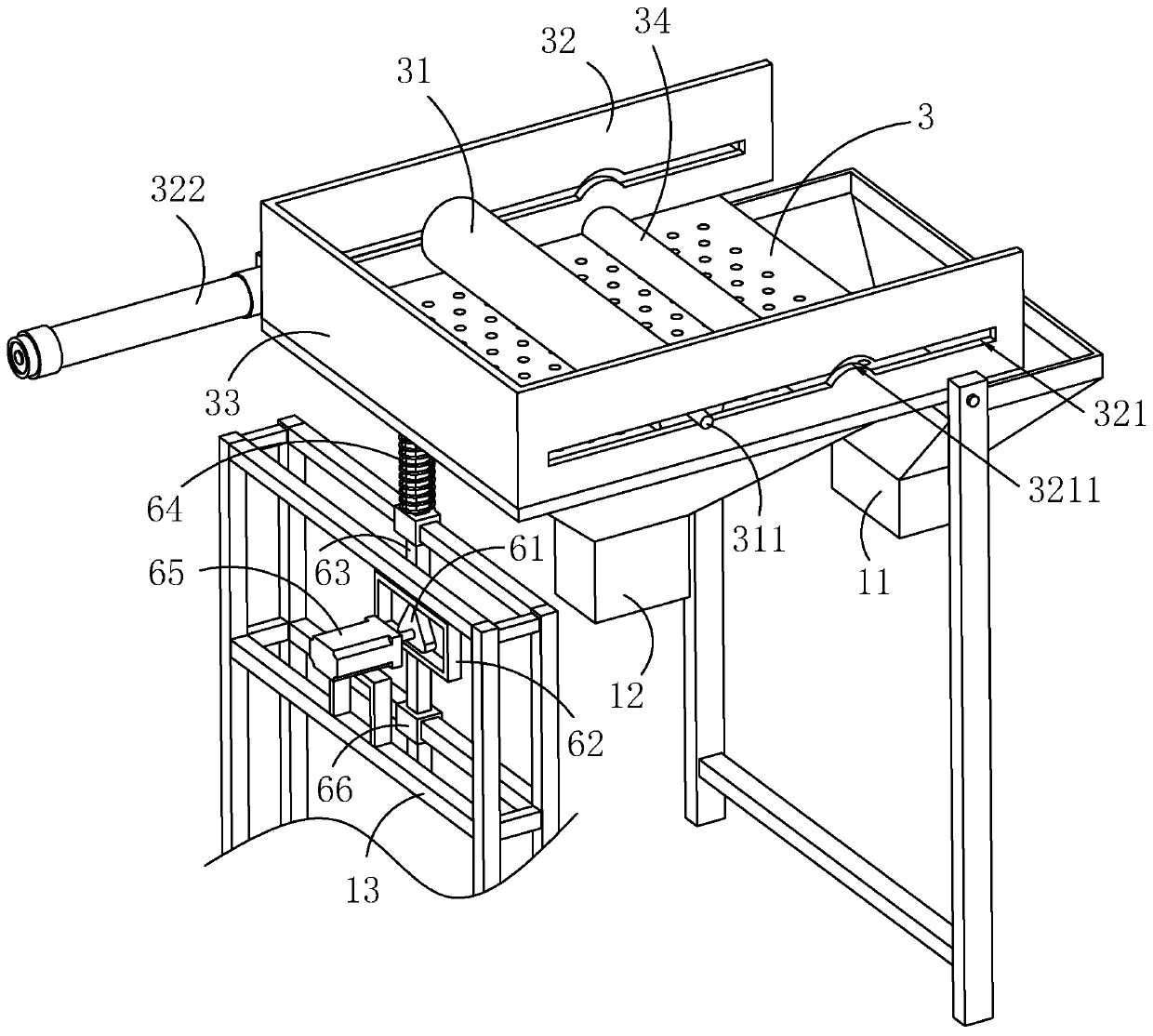

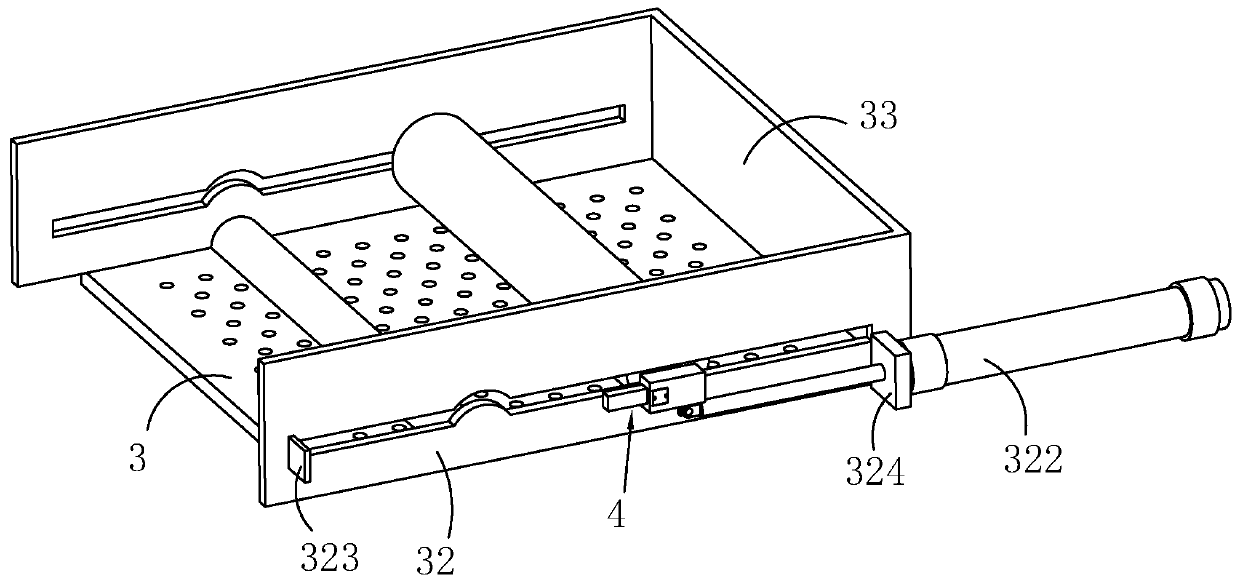

[0043] Such as figure 1 , 2 As shown, a device for comprehensive utilization of construction waste includes a frame 1 on which a pulverizer 2 for pulverizing construction waste is arranged. The pulverizer 2 includes a feed port 21 and a discharge port 22 . A screening plate 3 is arranged on the frame 1, and the screening plate 3 is made of a mesh plate, and the screening plate 3 is located directly below the discharge port 22.

[0044] Such as figure 1 , 2 As shown, a pressing roller 31 is arranged on the screening plate 3, an electromagnet (not shown in the figure) is arranged inside the pressing roller 31, a recovery bucket 11 is arranged on one side of the screening plate 3, and a There is a discharge hopper 12; the frame 1 is provided with a driving member for driving the pressure roller 31 to move closer to or away from the recovery hopper 11, and the driving member is an air cylinder 322.

[0045] Such as figure 1 , 2 As shown, the frame 1 is provided with a driving ...

Embodiment 2

[0059] A method for comprehensively utilizing construction waste, comprising the following steps:

[0060] S1. Sorting construction waste and removing plastic waste;

[0061] S2. Put the construction waste into the shredder 2 for crushing, the scrap iron is discharged through the recovery hopper 11, and other construction waste is discharged through the discharge hopper 12;

[0062] S3. The construction waste discharged from the discharge hopper 12 is used to make building materials such as building blocks, paving bricks, and lattice bricks.

[0063] The construction waste after preliminary classification is crushed by the shredder 2, and the crushed construction waste is discharged through the discharge hopper 12, and the scrap iron is discharged through the recovery hopper 11, which is convenient for recycling scrap iron; while other construction waste is used to make masonry Blocks, paving bricks, checkered bricks and other building material products to improve resource ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com