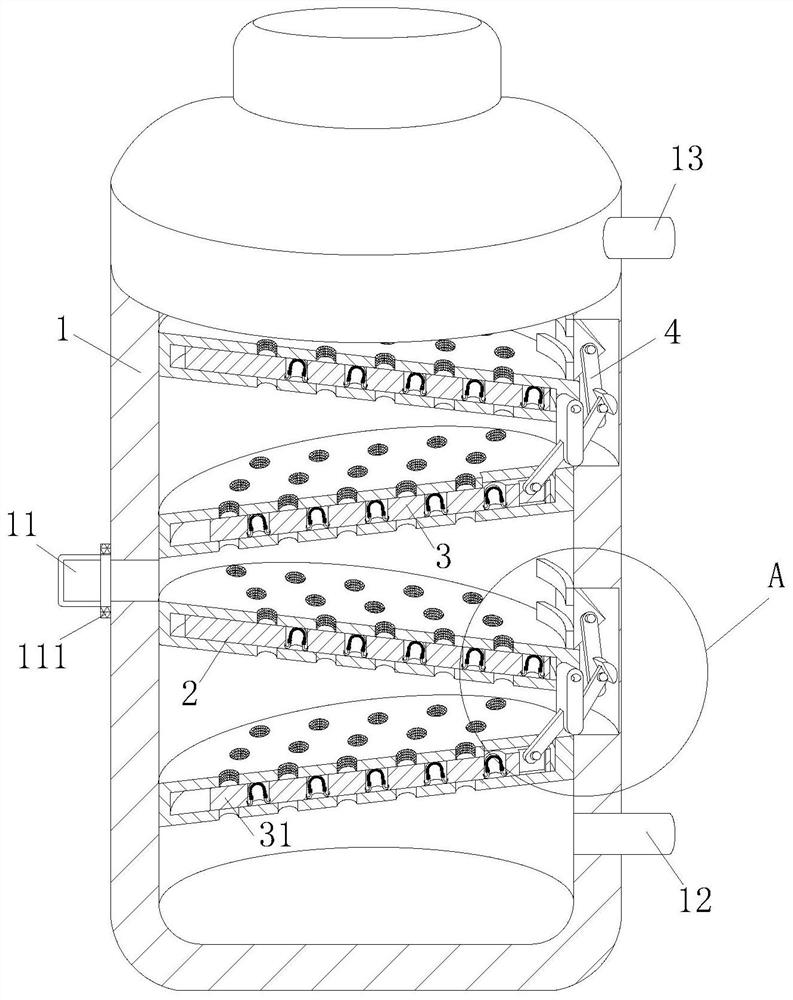

Plate-type fractionating tower

A fractionation tower and plate-type technology, applied in the field of plate-type fractionation towers, can solve the problems of reducing gas back-mixing, reducing liquid load, and not being able to fit completely, so as to achieve the effect of improving the fractionation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

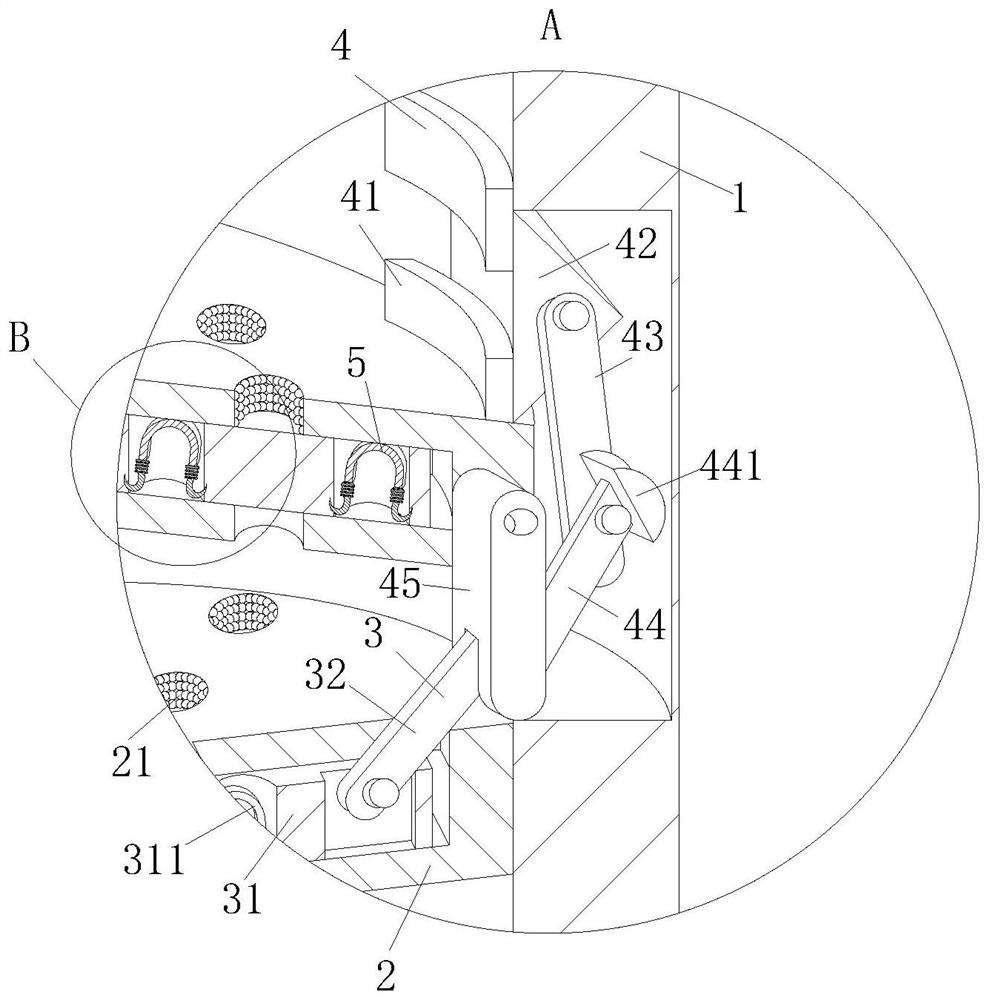

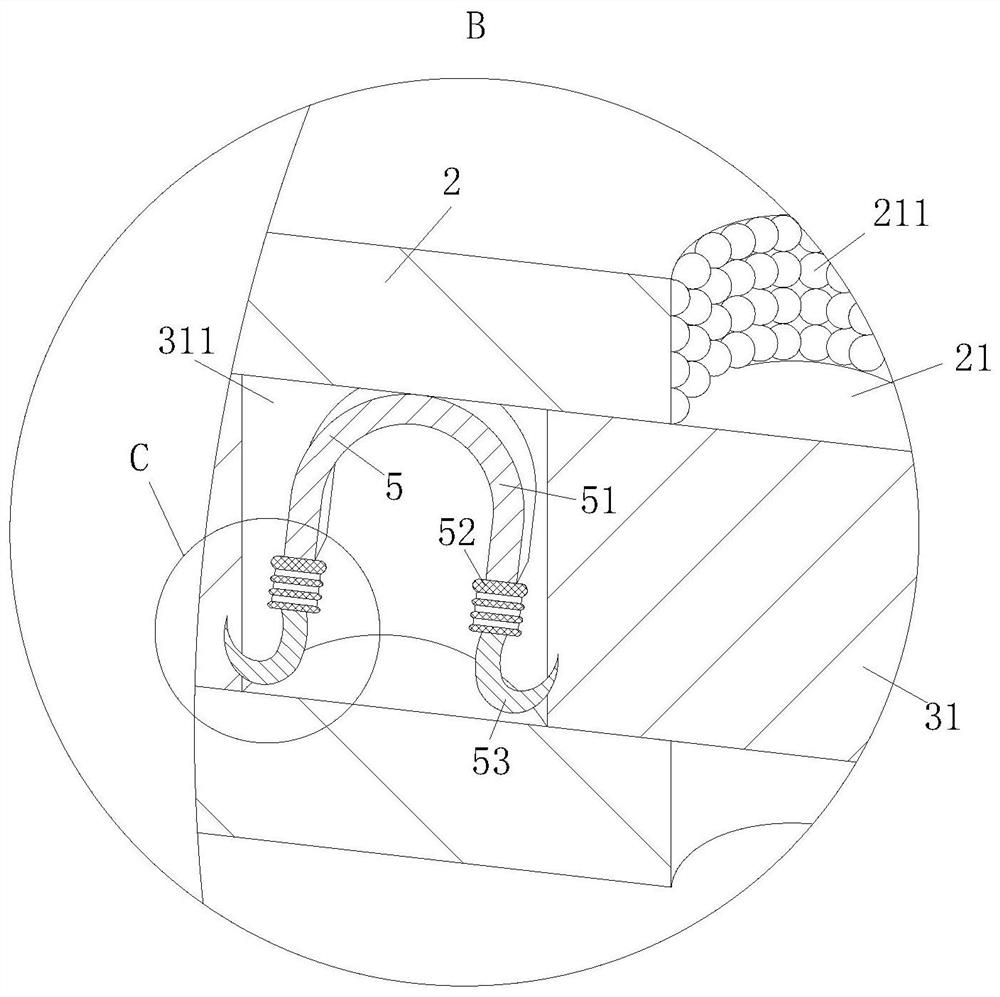

[0028] As a specific embodiment of the present invention, the control unit 3 includes a No. 2 plate 31 and a No. 3 rod 32; a group of No. 2 holes 311 are evenly arranged on the No. 2 plate 31, and the No. 2 plate 31 is placed in the groove In the channel, in the initial state, there is no communication between the No. 2 hole 311 and the No. 1 hole 21; one end of the No. 3 rod 32 is rotated and installed on the No. 1 plate 45, and the other end is hinged with the No. 2 plate 31, and each tray 2 There is an avoidance groove corresponding to the movement of No. 3 rod 32 on the top, through the mutual cooperation between No. 1 plate 45 and No. 3 rod 32, the communication between No. 1 hole 21 and No. 2 hole 311 is realized; when No. 1 plate 45 moves away from When one side of the groove moves, the No. 1 plate 45 pushes the No. 3 rod 32, so that the No. 2 plate 31 moves in the channel, and then realizes the communication between the No. 1 hole 21 and the No. 2 hole 311, so that two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com