C60 fullerene modified abrasion-resistant polyethylene composite material and preparation method thereof

A composite material and fullerene technology, which is applied in the field of C60 fullerene modified wear-resistant polyethylene composite material and its preparation, can solve the problems of poor fluidity, poor bending strength and creep performance, poor abrasive wear resistance, etc. problems, to achieve the effect of improving dispersibility and product performance, increasing tensile yield strength, and excellent lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

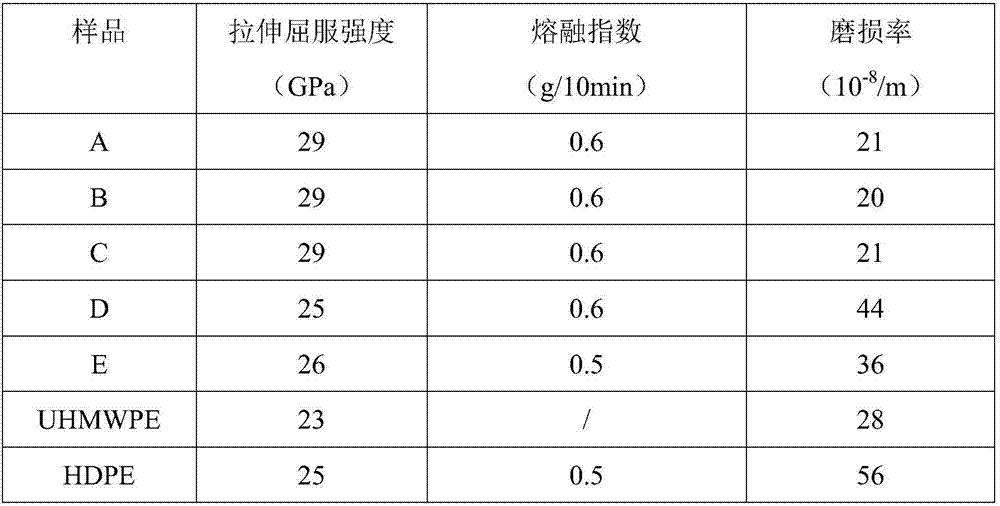

Examples

Embodiment 1

[0016] 1g of C60 fullerene was mixed with 4g of coupling agent KH550, and ultrasonically dispersed in 100ml of deionized water for 4 hours. The above mixture was centrifuged at 7200 rpm to remove the deionized water in the upper layer. Slowly remove all solvents in the solid product in the lower layer in the centrifugation step under vacuum in an oven at 50° C. to constant weight (TGA test confirmed that the grafted amount of KH550 is about 3.7 wt%). The resulting mixture was mixed with 90g high-density polyethylene, 6g maleic anhydride grafted polyethylene, 2g PE-b-PEO, 1g antioxidant 1076 and 1g heat stabilizer (dimethyl tin: dioctyl tin: tetraphenyl tin =3:10:7, mass ratio), feed into a twin-screw extruder (L / D=40), and melt blend at 210°C and 200rpm to obtain product A.

Embodiment 2

[0018] Mix 4g of C60 fullerene with 1g of coupling agent A-151, and ultrasonically disperse in 1000ml of deionized water for 3 hours. The above mixture was centrifuged at 7200 rpm to remove the deionized water in the upper layer. All solvent in the lower solid product from the centrifugation step was slowly removed under vacuum in a 50°C oven to constant weight. Mix the obtained mixture with 80g high-density polyethylene, 5g maleic anhydride grafted polyethylene, 6g PE-b-PEO, 1g antioxidant 168 and 1g heat stabilizer (dimethyl tin: dioctyl tin = 1: 1, mass ratio), into a twin-screw extruder (L / D=40), melt blending under the conditions of 185° C. and 230 rpm to obtain product B.

Embodiment 3

[0020] Mix 5g of C60 fullerene with 5g of coupling agent KH791, emulsify and disperse in 200ml of deionized water for 5 hours. The above mixture was centrifuged at 7200 rpm to remove the deionized water in the upper layer. All solvent in the lower solid product from the centrifugation step was slowly removed under vacuum in a 50°C oven to constant weight. The resulting mixture and 100g high-density polyethylene, 6g maleic anhydride grafted polyethylene, 8g PE-b-PEO, 1g antioxidant DLTDP and 1g tetraphenyl tin add twin-screw extruder (L / D= 40), melt blending under the conditions of 240° C. and 180 rpm to obtain product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com