Polylactic acid resin composition, and method for producing molded article and polylactic acid resin composition

A technology of polylactic acid resin and composition, applied in the field of polylactic acid resin composition, can solve the problems of small crystallization temperature and crystallization enthalpy, decrease in crystallization characteristics, etc., and achieve the effect of maintaining crystallinity, high crystallinity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

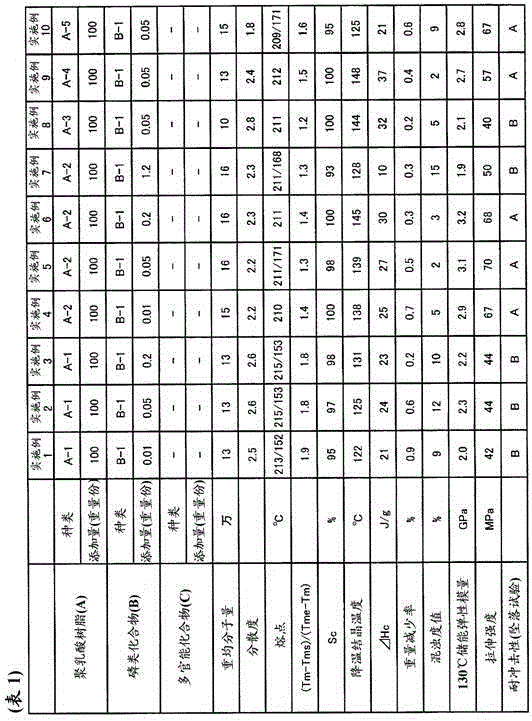

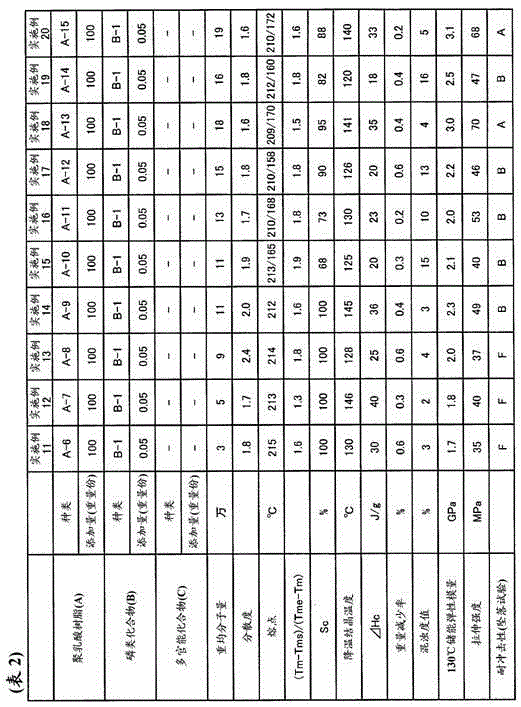

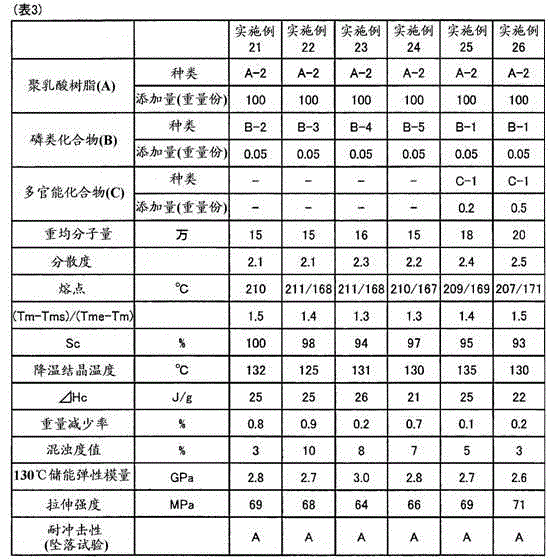

Examples

preparation example Construction

[0123]

[0124] The method for preparing the polylactic acid block copolymer is not particularly limited, and a general method for preparing polylactic acid can be used. Specifically, there is a method in which either L-lactide or D-lactide, which is a cyclic dimer produced from lactic acid as a raw material, is subjected to ring-opening polymerization in the presence of a catalyst, and then added as the polylactic acid Lactide of the optical isomer and ring-opening polymerization to obtain the lactide method of polylactic acid block copolymer (preparation method 1); the raw material is obtained by direct polymerization or via ring-opening polymerization of lactide A method in which poly-L-lactic acid and poly-D-lactic acid are polymerized separately, followed by solid phase polymerization after mixing the obtained poly-L-lactic acid and poly-D-lactic acid to obtain a polylactic acid block copolymer (manufacturing method 2); by carrying out long-term melting and kneading of ...

Embodiment

[0289] Examples and the like are given below to illustrate the present invention, but the present invention is not limited by these examples. Here, the parts in the examples represent parts by weight. The measurement methods of physical properties and the like are as follows. In addition, the same part was selected and measured as the measurement site|part of a molded object.

[0290] (1) Molecular weight

[0291] The weight average molecular weight and degree of dispersion are values in terms of standard polymethyl methacrylate measured by gel permeation chromatography (GPC). The GPC measurement was performed as follows: a differential refractometer WATERS410 manufactured by WATERS Co., Ltd. was used as a detector, MODEL510 manufactured by WATERS Co., Ltd. was used as a pump, and Shodex (registered trademark) GPC HFIP-806M and Shodex (registered trademark) GPC manufactured by Showa Denko Co., Ltd. were used as columns. Columns of HFIP-LG connected in series. The measure...

reference example 1

[0334] 50 parts of 90% L-lactic acid aqueous solution was put into the reaction container equipped with the stirring device and the reflux device, and after making temperature into 150 degreeC, it was made to react for 3.5 hours, decompressing slowly and distilling off water. Then, after returning to normal pressure under a nitrogen atmosphere and adding 0.02 parts of tin(II) acetate, the polymerization reaction was performed for 7 hours while gradually reducing the pressure to 13 Pa at 170°C. Next, the obtained poly-L-lactic acid was subjected to crystallization treatment at 110° C. for 1 hour under a nitrogen atmosphere, and then solid-phase polymerization at 140° C. for 3 hours under a pressure of 60 Pa, and solid-state polymerization at 150° C. for 3 hours. Phase polymerization was performed at 160° C. for 5 hours to obtain poly-L-lactic acid (PLA1). The weight average molecular weight of PLA1 is 43,000, the degree of dispersion is 1.8, and the melting point is 159°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com