Thermoplastic polyurethane elastomer composite material, preparation method and application thereof

A technology of thermoplastic polyurethane and composite materials, which is applied in the field of 3D printing of melt molding and elastomer materials, and can solve the problems of complicated preparation methods, inability to obtain excellent elasticity of thermoplastic polyurethane, and increased operation complexity and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Mix silane coupling agent KH550, which accounts for 0.1% of the total mass of the filler, with absolute ethanol at a mass ratio of 1:6, add it to the filler, mix and stir evenly, and dry it in an oven at 80°C to obtain a surface-treated filler .

[0045] 30 copies of Wanhua 1180 polyester TPU, 0.1 part of mica with a layer spacing of 0.5nm and a thickness of 0.9nm and 1 part of TiO with an average particle size of 2um 2 Particles, primary antioxidant 0.01 part triethylene glycol bis[β-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate], auxiliary antioxidant 0.01 part triphosphite (2.4-Di-tert-butylphenyl) ester, 0.02 parts of polyethylene with a number average molecular weight of 2000 and 1 part of colorant silver white pearl powder were added to a high mixer and mixed evenly. The mixed material is extruded and granulated in a twin-screw extruder.

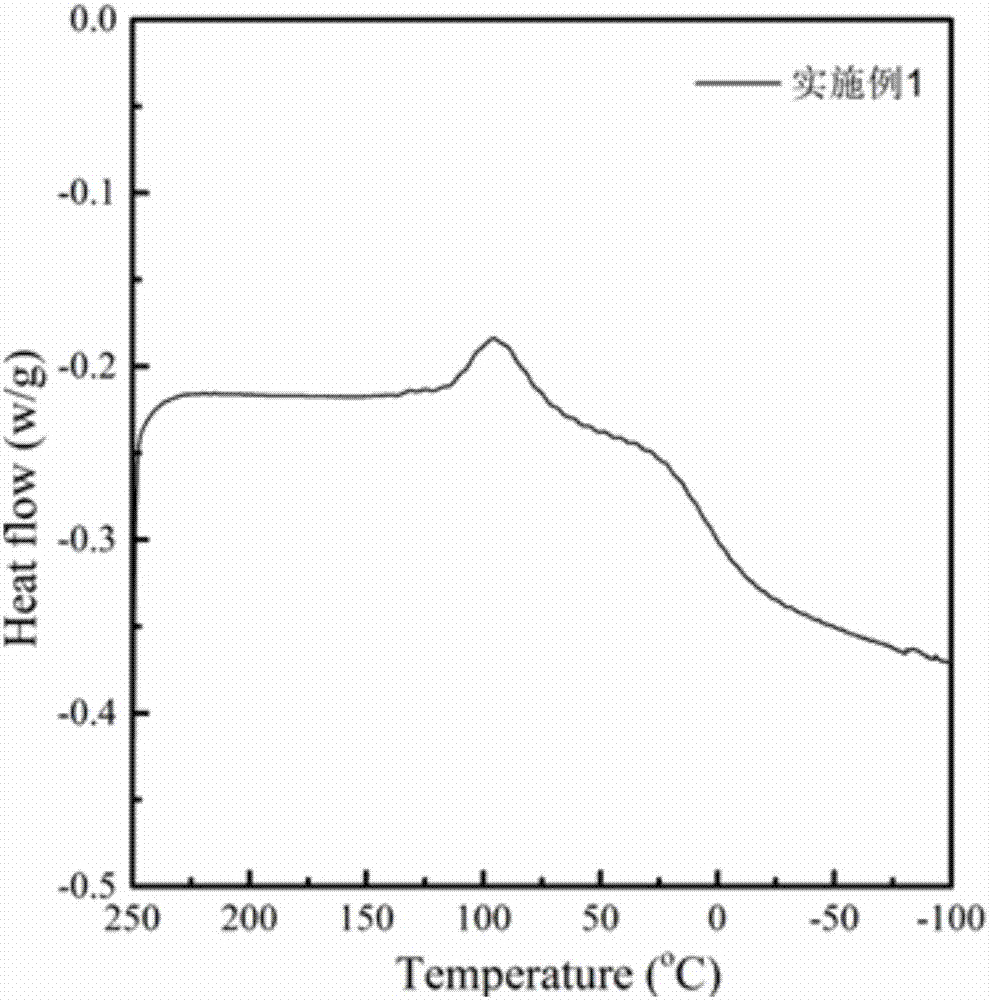

[0046] For differential scanning calorimetry data, see figure 1 , the crystallization start temperature is 122°C, t...

Embodiment 2

[0049] Mix silane coupling agent KH560 accounting for 1.0% of the total mass of the filling with anhydrous methanol at a mass ratio of 1:6, add it to the filling, mix and stir evenly, and dry in an oven at 80°C to obtain a surface-treated filling .

[0050] 65 copies of Wanhua 1185 polyester TPU, 7.5 parts of montmorillonite with a layer spacing of 1nm and a thickness of 2nm, 2.5 parts of glass microspheres with an average particle size of 10um, and 0.08 parts of four-[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionate] pentaerythritol ester, 0.12 part of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide and 0.8 part of stearamide are added into the high mixer and mixed evenly. The mixed material is extruded and granulated in a twin-screw extruder.

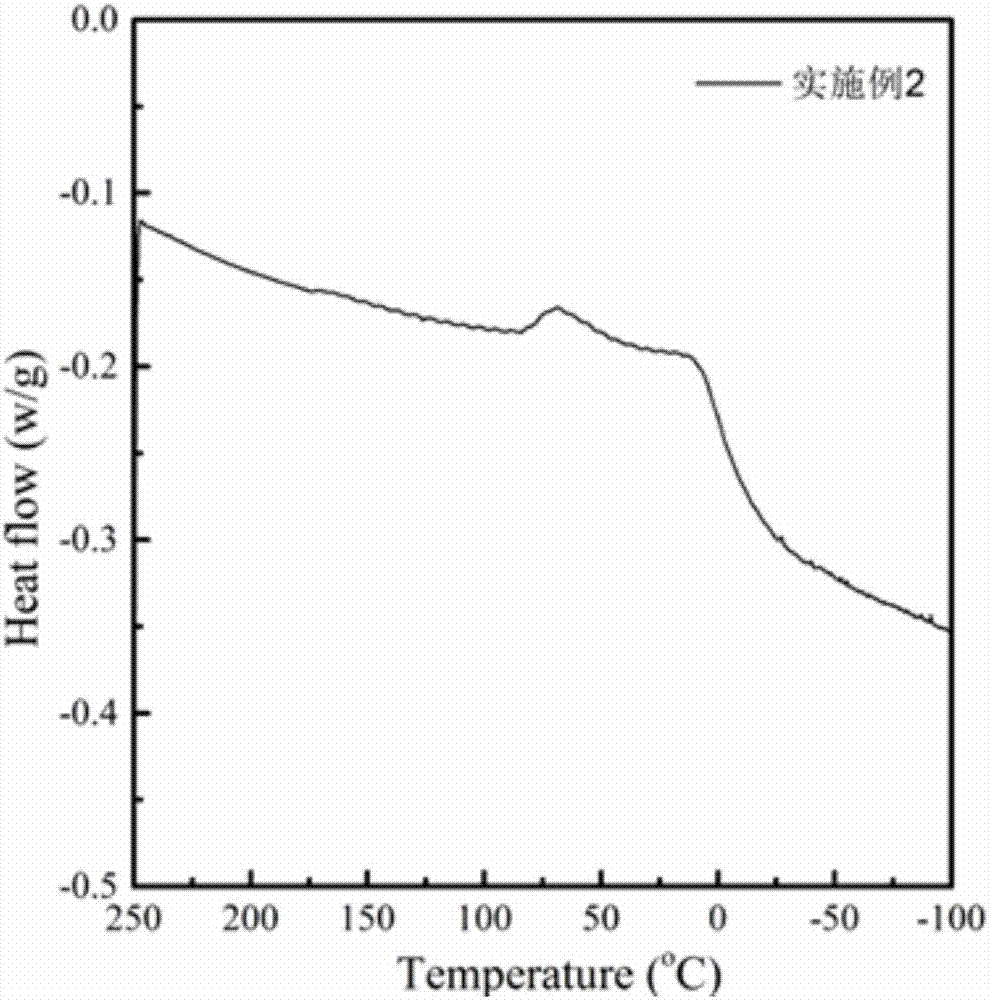

[0051] For differential scanning calorimetry data, see figure 2 , the crystallization start temperature is 85.7°C, the maximum crystallization enthalpy temperature is 68.5°C, and the crystallization end temperature is 34.7°C. T...

Embodiment 3

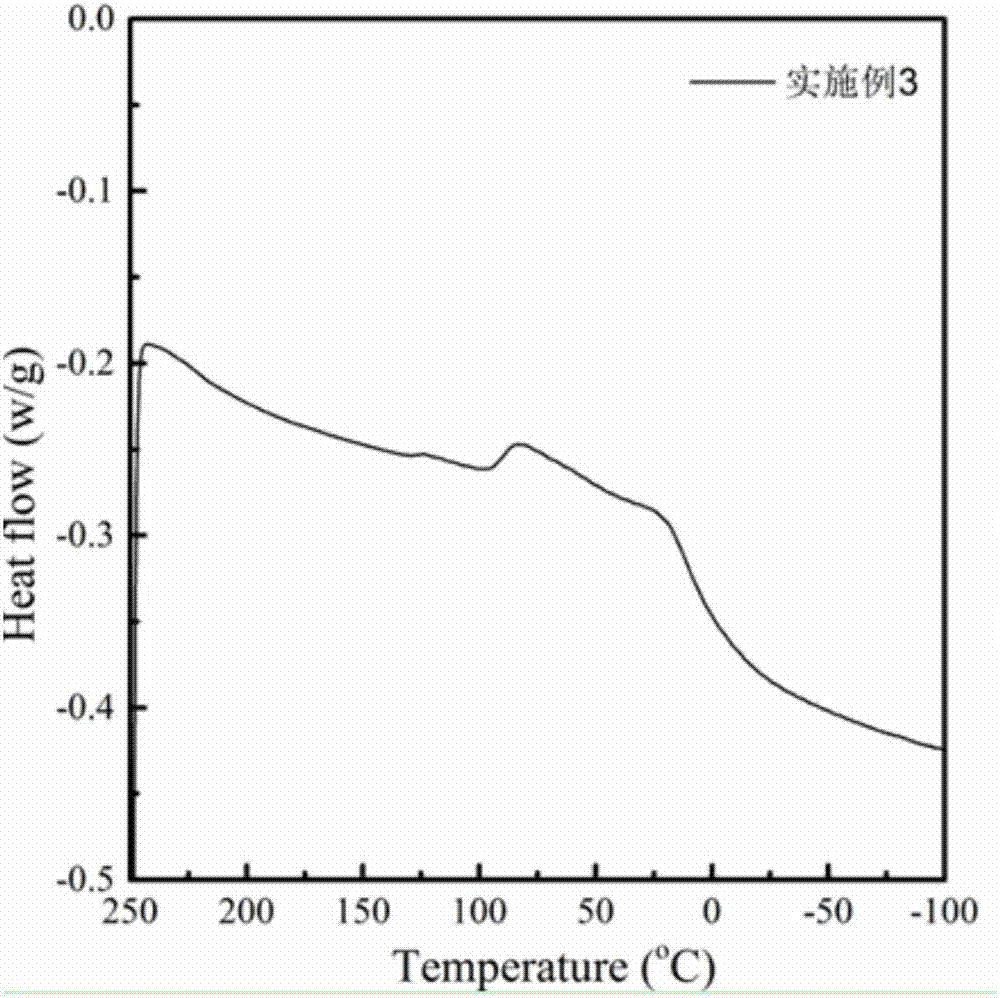

[0054] Mix silane coupling agent KH550 accounting for 1.5% of the total mass of the filling with isopropanol at a mass ratio of 1:6, add it to the filling, mix and stir evenly, and dry in an oven at 80°C to obtain a surface-treated filling . 70 copies of Wanhua 1295 polyester TPU, 11.8 parts of talc powder with a layer spacing of 1.5nm and a thickness of 10nm, and 3.2 parts of Al with an average particle size of 10um 2 o 3 , 0.13 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate as main antioxidant, 0.26 parts of β,β'-thiodipropionic acid as auxiliary antioxidant Dilauryl ester and 0.2 part of ethylenediamine bis stearylamide are added into a high mixer and mixed evenly. The mixed material is extruded and granulated in a twin-screw extruder. For differential scanning calorimetry data, see image 3 , the crystallization start temperature is 96°C, the maximum crystallization enthalpy temperature is 83.2°C, and the crystallization end temperature is 36.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com