Special air conditioner wind wheel material with high rigidity, high heat resistance and low shrinkage, and preparation method of special air conditioner wind wheel material

A technology with high heat resistance and shrinkage, applied in the field of patented materials for air-conditioning wind wheels and their preparation, can solve the problems of inability to meet the use requirements of air-conditioning wind wheels, poor dimensional stability of products, and easy warping and deformation, and achieve recycling and repeatability. Easy to use, less machine wear, and the effect of overcoming the difficulty of mold adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

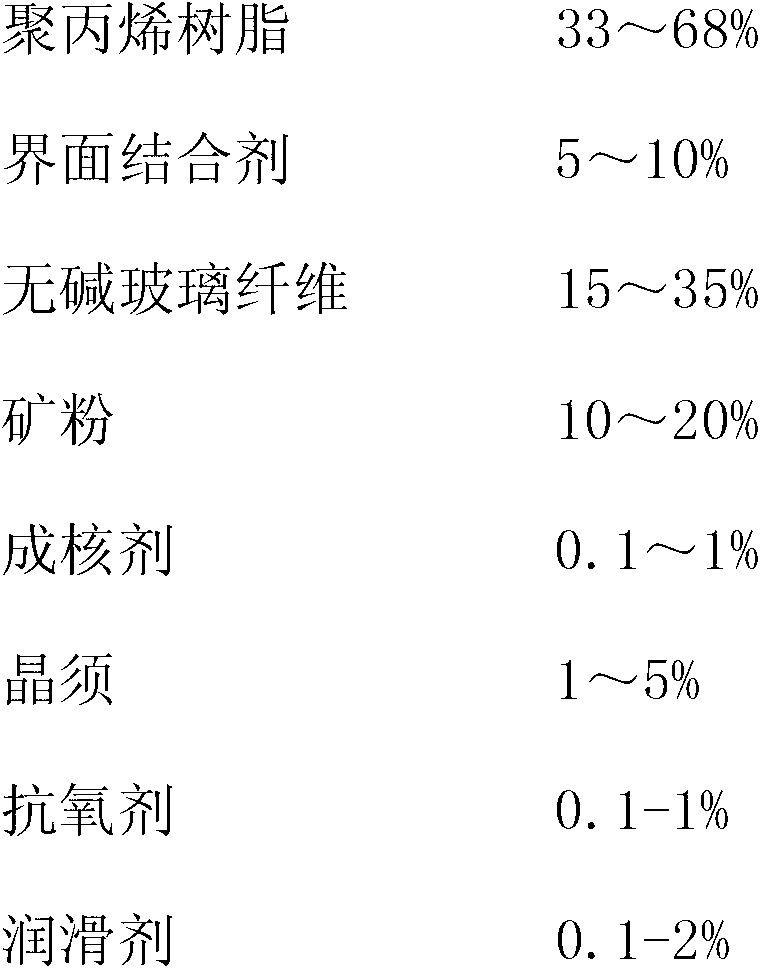

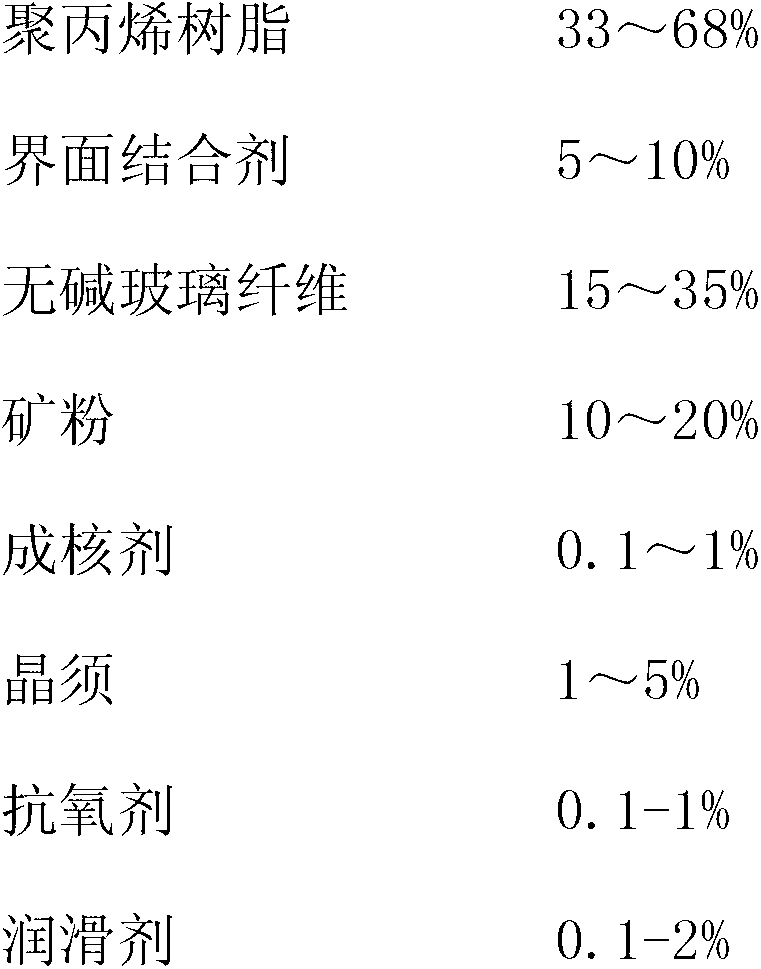

Method used

Image

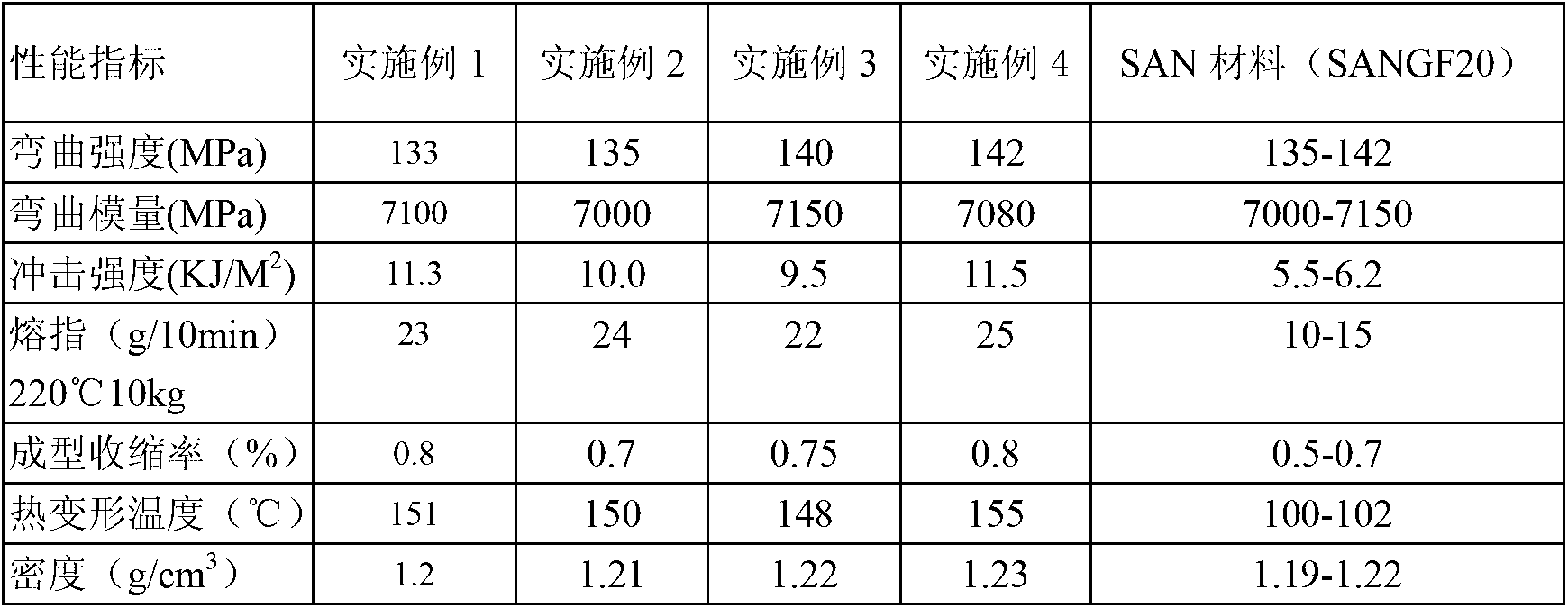

Examples

Embodiment 1

[0024] Embodiment 1 (preparation of 100Kg special material for air conditioner wind wheel of the present invention):

[0025] In this embodiment, a high-rigidity, high-heat-resistant, low-shrinkage air-conditioning wind wheel special material and its preparation method use polypropylene resin as the base material, alkali-free glass fiber as the stiffener, PE-g-MAH as the interface binder, crystal Whiskers and nucleating agents are compounded as auxiliary stiffening and heat-resistant agents. 1010 / 168 and calcium stearate are anti-oxidant lubrication systems. They are prepared by melt blending technology using twin-screw extruder equipment. The process: Weigh 42kg of polypropylene resin, 10kg of interface binder PE-g-MAH, 1kg of calcium stearate, mix in a high-speed mixer for 1 minute, then add 5kg of calcium carbonate whiskers, 0.5kg of sorbitol, anti-oxidant Agent 1010 / 168 (mass ratio 1:1.5) 0.5kg in total, stir at high speed for 2 minutes, then add 11kg of muscovite powder, ...

Embodiment 2

[0026] Embodiment 2 (preparation of 100Kg special material for air conditioner wind wheel of the present invention):

[0027] In this embodiment, polypropylene resin is used as base material, alkali-free glass fiber is used as stiffening agent, PP-g-MAH is used as interface binder, whiskers and nucleating agent are compounded as auxiliary stiffening and heat-resistant agent, 1076, hard Magnesium fatty acid is an anti-oxidant lubrication system, which is prepared by melt blending technology using twin-screw extruder equipment. The process: Weigh 55kg of polypropylene resin, 5kg of interface binder PP-g-MAH, 2kg of magnesium stearate, mix in a high-speed mixer for 1 minute, then add 1kg of calcium sulfate whiskers, 1kg of sorbitol derivatives, 1kg Antioxidant 1076, stir at high speed for 2 minutes, then add sericite powder / muscovite powder (mass ratio 1:1) in total 20kg, after stirring at high speed for 5 minutes, discharge the compound evenly, and add the compound to the twin-s...

Embodiment 3

[0028] Embodiment 3 (preparation of 100Kg special material for air conditioner wind wheel of the present invention):

[0029] In this example, polypropylene resin is used as the base material, alkali-free glass fiber is used as the stiffening agent, POE-g-MAH / POE-g-GMA is used as the interface binder, and whiskers and nucleating agents are compounded to assist stiffening and resistance. Thermal agent, 1010, EBS is an anti-oxidation lubrication system, which is prepared by melt blending technology using twin-screw extruder equipment. The process: Weigh 43.7kg of polypropylene resin, 8kg of interface binder POE-g-MAH / POE-g-GMA (mass ratio 1:0.5), 0.1kg of EBS, mix in a high-speed mixer for 1 minute, and then add Magnesium oxide whiskers 3kg, carboxylic acid metal salt nucleating agent 0.1kg, 0.1kg antioxidant 1010, after stirring at high speed for 2 minutes, add barite powder 10kg again, after stirring at high speed for 5 minutes, evenly discharge the compounding material, Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com