Pole piece of negative electrode and preparation method of pole piece as well as lithium-ion battery using negative electrode

A negative electrode sheet and negative electrode technology, which is applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of increased cost and complicated process, and achieve the effects of improving compaction density, simple and easy preparation method, and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

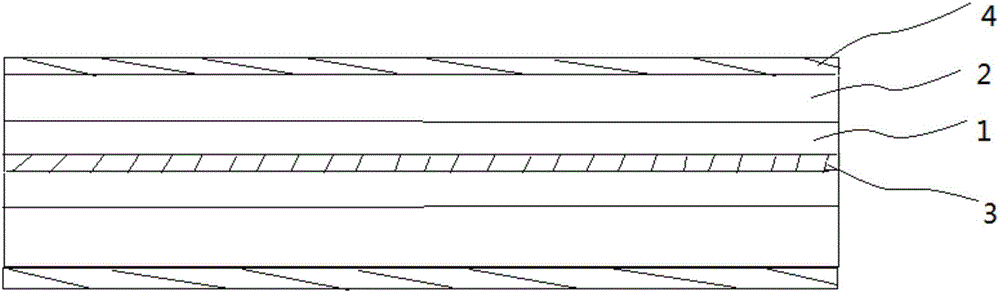

[0047] The present application also relates to the preparation method of the negative electrode sheet, which method selects any one of the following methods:

[0048] 1) One layer of graphite coating slurry is coated on one side of the negative electrode current collector, and dried to obtain a graphite coating; a layer of hard carbon coating slurry is coated on the graphite coating, and dried to obtain a hard carbon coating; Prepare graphite coating and hard carbon coating successively in the same manner and order on the other side of the negative electrode current collector;

[0049] 2) One layer of hard carbon coating slurry is coated on one side of the negative electrode current collector, and dried to obtain a hard carbon coating; a layer of graphite coating slurry is coated on the hard carbon coating, and dried to obtain a graphite coating; On the other side of the negative electrode collector, prepare a hard carbon coating and a graphite coating in the same manner and i...

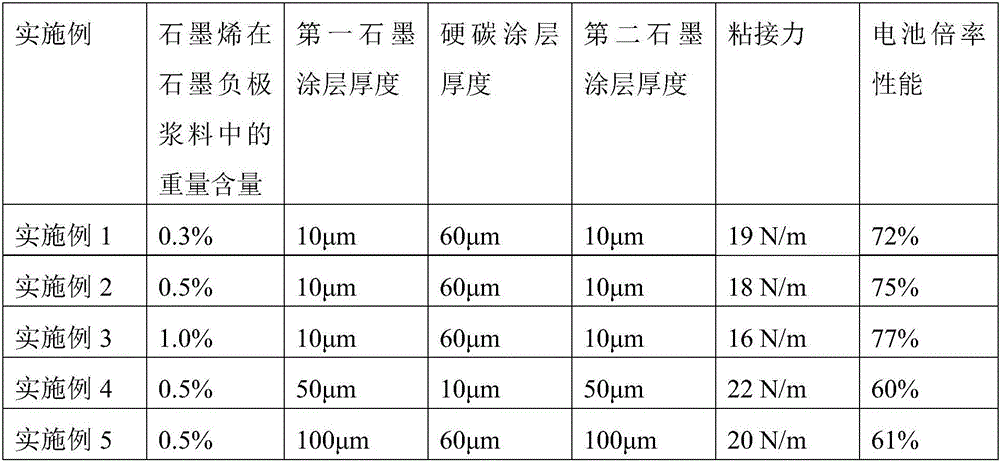

Embodiment 1~5

[0056] LiCoO 2 As the positive electrode material, it is mixed with the conductive agent Super P and the binder polyvinylidene fluoride (PVDF) at a mass ratio of 90:5:5, and the solvent N-methylpyrrolidone is added, and the positive electrode slurry is obtained after mixing and stirring. Coating, cold pressing, slitting, and cutting into pieces to obtain positive pole pieces.

[0057] Mix and stir graphite, conductive agent (mixture of Super P and graphene), binder PVDF and solvent N-methylpyrrolidone to obtain graphite negative electrode slurry. The hard carbon negative electrode slurry is obtained after mixing and stirring polyacrylonitrile-based hard carbon powder, conductive agent Super P, binder PVDF and solvent N-methylpyrrolidone. Wherein in the graphite negative electrode slurry, the mass ratio of graphite, conductive agent and binder is 97:1.5:1.5, and the weight content of graphene in the graphite negative electrode slurry is 0.3-1.0%. In the hard carbon negative e...

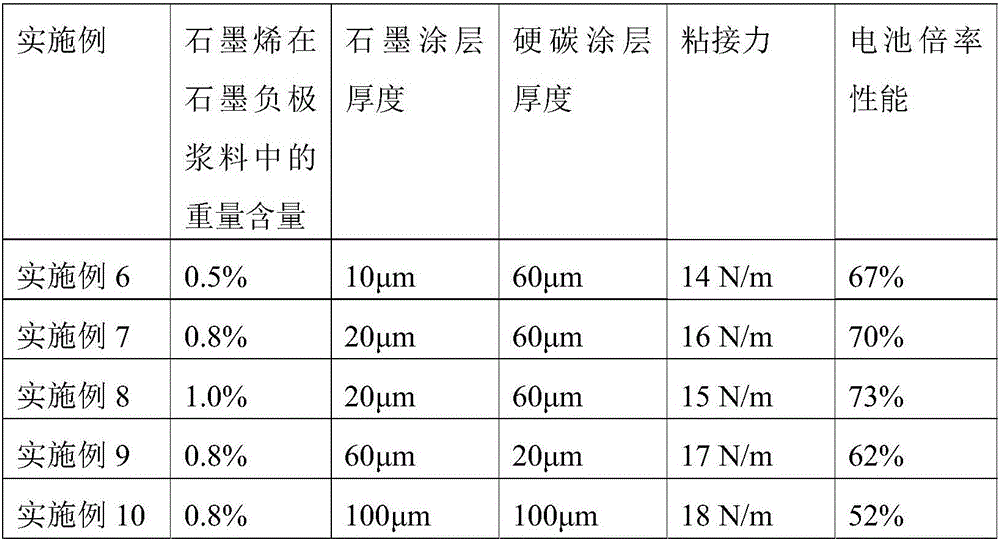

Embodiment 6~10

[0067] The preparation methods of the positive electrode sheet, the graphite negative electrode slurry, and the hard carbon negative electrode slurry are the same as in Example 1. First coat the above-mentioned graphite negative electrode slurry on the copper foil of the negative electrode current collector, and the thickness of the coating film is 10-100 μm to obtain a graphite coating; after drying at 110°C for 2-3 hours, then coat the hard carbon negative electrode slurry, and the thickness of the coating film is 10-100 μm to obtain a hard carbon coating, and dry at 110°C for 2-3 hours. On the other side of the copper foil, apply the graphite negative electrode slurry and the hard carbon negative electrode slurry respectively in the same method and order as above. The above pole pieces were cold-pressed, stripped, and cut into pieces to obtain the negative pole pieces of Examples 6-10, the structure of which was graphite / hard carbon. The coating thicknesses of the negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com