Method for preparing and controlling second phase homogenization in high-aluminum-content cast-rolled magnesium alloy plate

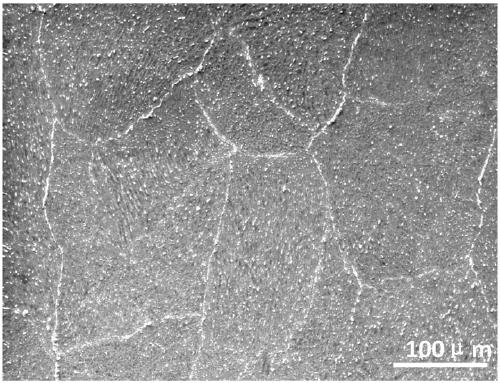

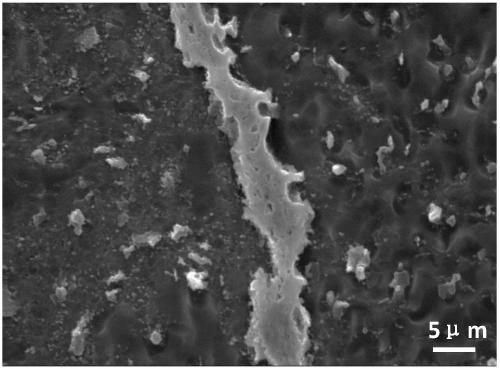

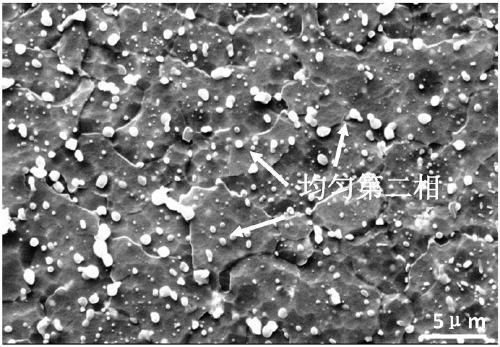

A magnesium alloy and homogenization technology is applied in the field of second phase homogenization control and preparation in cast-rolled magnesium alloy sheets with high aluminum content, which can solve the problems of difficulty in plastic processing and forming of cast-rolled magnesium alloy sheets with high aluminum content, and achieve microstructure. The effect of uniformity, avoiding tiny cracks and strong docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Heating step solution treatment: the casting and rolling ATZ821 magnesium alloy billet is subjected to stage one solid solution, the solution temperature of stage one is 400°C, the holding time is 24h, and then the temperature is raised to carry out stage two solid solution, and the stage two solid solution The temperature is 430°C, the holding time is 16h, and the second phase is fully solid-dissolved;

[0027] (2) High-temperature multi-pass rolling deformation: carry out 10 high-temperature rolling deformations to the second-phase fully solid-solution billet described in step (1), and the reduction of each pass is 11%. Insulate for 10 minutes at a temperature of 350°C for a short time, and then roll to obtain a magnesium alloy plate;

[0028] (3) Multi-pass rolling deformation at lower temperature: the magnesium alloy plate described in step (2) is subjected to 2-pass cooling rolling deformation, the reduction of each pass is 13%, and the temperature of 300° C. ...

Embodiment 2

[0031] (1) Heating step solution treatment: the casting and rolling ATZ821 magnesium alloy billet is subjected to stage one solid solution, the solution temperature of stage one is 380°C, the holding time is 26h, and then the temperature is raised to carry out stage two solid solution, and the stage two solid solution The temperature is 400°C, the holding time is 18h, and the second phase is fully solid-dissolved;

[0032] (2) High temperature multi-pass rolling deformation: carry out 8 high-temperature rolling deformations to the second phase fully solid-solution billet described in step (1), the reduction of each pass is 15%, and each pass Hold the temperature for 9 minutes at 380°C for a short time, and roll to obtain magnesium alloy plates;

[0033] (3) Multi-pass rolling deformation with cooling: the magnesium alloy plate described in step (2) is subjected to 2-pass cooling rolling deformation, the reduction of each pass is 13%, and the temperature of 330° C. Under short...

Embodiment 3

[0036] (1) Heating step solution treatment: the casting and rolling ATZ821 magnesium alloy billet is subjected to stage one solid solution, the solution temperature of stage one is 350°C, the holding time is 28h, and then the temperature is raised to carry out stage two solid solution, and the stage two solid solution The temperature is 450°C, the holding time is 12h, and the second phase is fully solid-dissolved;

[0037] (2) High-temperature multi-pass rolling deformation: carry out 9 high-temperature rolling deformations to the second-phase fully solid-solution billet described in step (1), the reduction of each pass is 12%, and each pass Hold the temperature for 20 minutes at 300°C for a short time, and roll to obtain magnesium alloy plates;

[0038] (3) Multi-pass rolling deformation with cooling: the magnesium alloy plate described in step (2) is subjected to 3 passes of cooling rolling deformation, the reduction in each pass is 12%, and the temperature is 275°C before e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com