Method for refining grain structure of nickel-based alloy forging by regulating and controlling deformation temperature

A nickel-based alloy, deformation temperature technology, applied in the field of forging, can solve problems such as high cost and high energy consumption, and achieve the effect of inhibiting grain growth and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

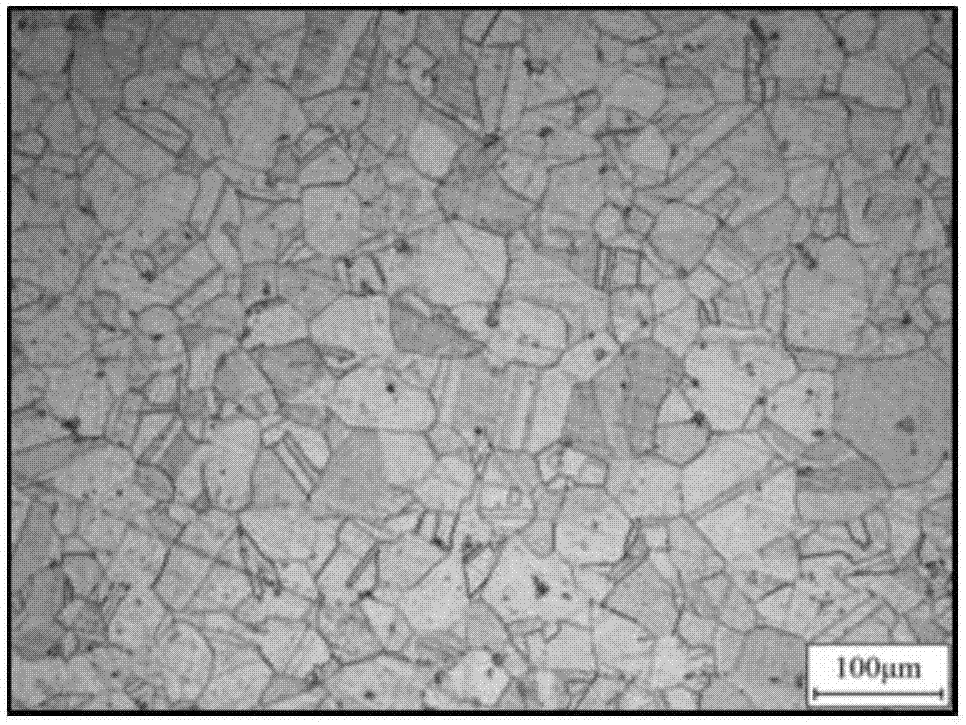

[0022] Step 1: The nickel-based alloy forging billet is subjected to solution treatment, the solution temperature is 1040°C, the solution time is 45 minutes, and then quenched in water, the obtained grain structure is as follows figure 1 shown;

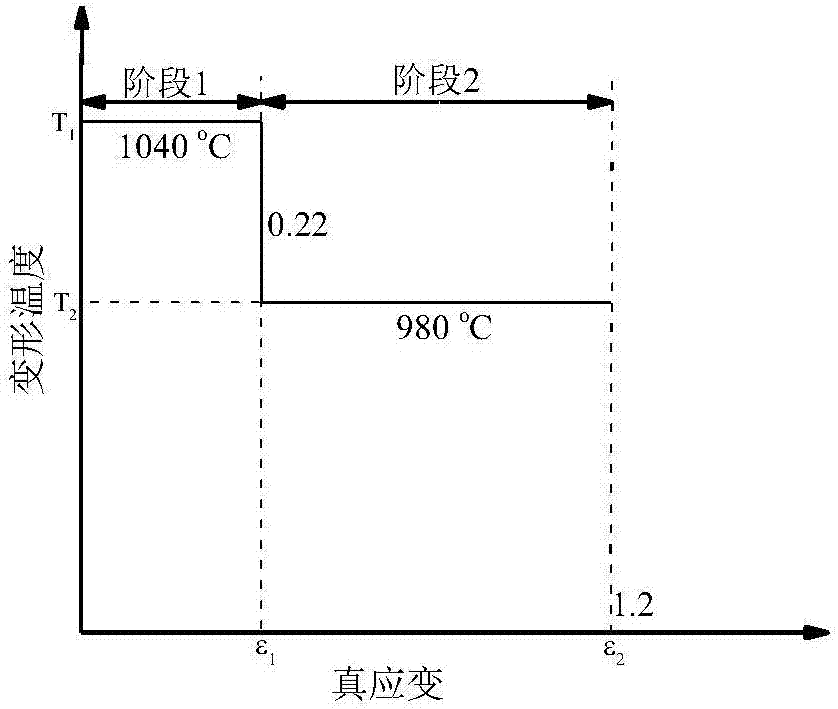

[0023] Step 2: Plastic deformation of the solution-treated nickel-based alloy forging billet with a strain rate of 0.01s -1 , first heat the forging billet to the deformation temperature of 1040°C, and wait until the temperature of the forging billet is uniform and then start to deform. The deformation process includes two stages. The cooling rate of 5°C / s reduces the deformation temperature to 980°C, and the second stage of deformation begins after the temperature of the forging billet is kept uniform. The total deformation of the forging billet in the two stages is 70% (true strain 1.2). Example The relationship between deformation temperature and strain of 1 is as follows figure 2 shown;

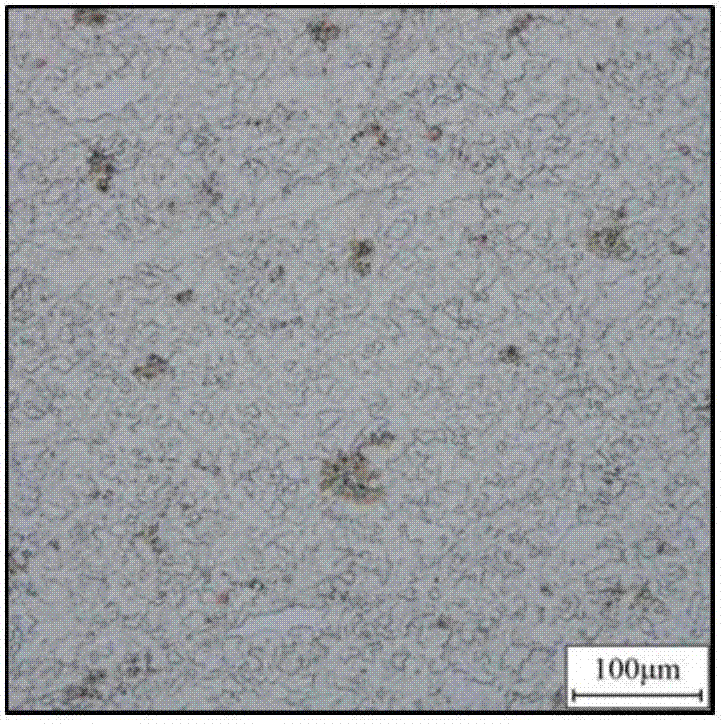

[0024] Step 3: Immediately after the d...

Embodiment 2

[0027] Step 1: The nickel-based alloy forging billet is solution treated, the solution temperature is 1040°C, the solution time is 45min, and then quenched, the obtained grain structure is as follows figure 1 shown;

[0028] Step 2: Plastic deformation of the solution-treated nickel-based alloy forging billet with a strain rate of 0.01s -1 , first heat the forging billet to the deformation temperature of 1040°C, and wait until the temperature of the forging billet is uniform and then start to deform. The deformation process is divided into two stages. The deformation amount of the first stage is 40% (true strain 0.51). Reduce the deformation temperature to 980°C at a cooling rate of 5°C / s, and start the second stage of deformation after the heat preservation until the temperature of the forging billet is uniform. The total deformation of the forging billet in the two stages is 70% (true strain 1.2), implement The relationship between deformation temperature and strain of Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com