Preparation method for zinc sulfide-graphene nanocomposite

A nano-composite material, zinc sulfide technology, applied in zinc sulfide, nanotechnology, nanotechnology and other directions, can solve the problems of complex process, many influencing factors, not suitable for scaled production, etc., to achieve short synthesis cycle, avoid agglomeration, good quality The effect of fluorescence quenching properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of zinc sulfide-graphene nanocomposite material is characterized in that, comprises the following steps:

[0029] (1) Preparation of zinc-mercapto complexes: the molar ratio of the sulfur-containing ligand and the zinc salt substance is 2:1, dissolved in an appropriate amount of deionized water or an organic solvent and mixed for reaction, and the sulfur-containing ligand is mercaptobenzo One of thiazole, mercaptoethanol, dodecyl mercaptan, the zinc salt is ZnCl 2 , Zn(NO 3 ) 2 , ZnSO 4 , Zn(CH 3 COO) 2 One of the above, the organic solvent is one of methanol, ethanol, ethylene glycol, isopropanol, ether, dimethylformamide, magnetically stirred for 30-60min, and then centrifuged with organic solvent and deionized water Wash 1 to 3 times, collect milky white precipitate, and vacuum dry for 10 to 30 hours to obtain zinc-mercapto complex;

[0030] (2) Preparation of sintered body: Weigh a certain amount of zinc-mercapto complex, spread it...

Embodiment 1

[0033] Weigh 5mmolZnCl 2 Dissolve in 30mL ethanol, take another 10mmol mercaptobenzothiazole (HMBT) and dissolve it in 50mL ethanol, then mix the two solutions thoroughly to obtain milky white precipitate Zn(MBT) 2 , after magnetic stirring for 30min, wash with ethanol and deionized water for 3 times, collect the milky white precipitate, and dry it in vacuum for 24h to obtain Zn(MBT) 2 .

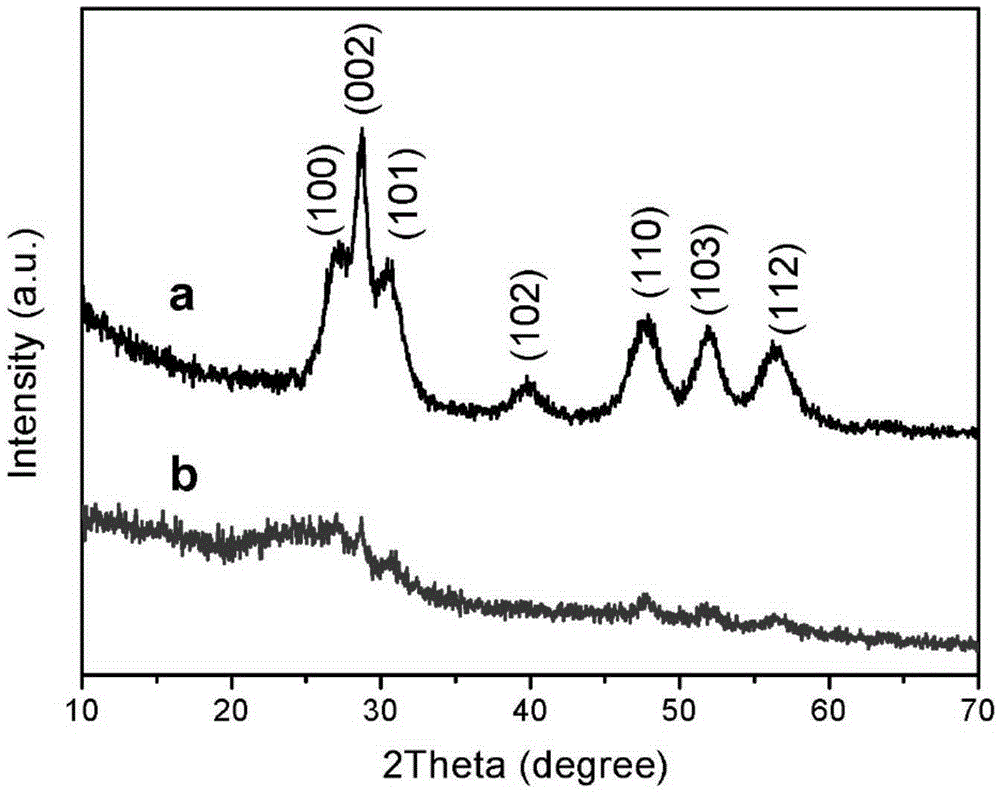

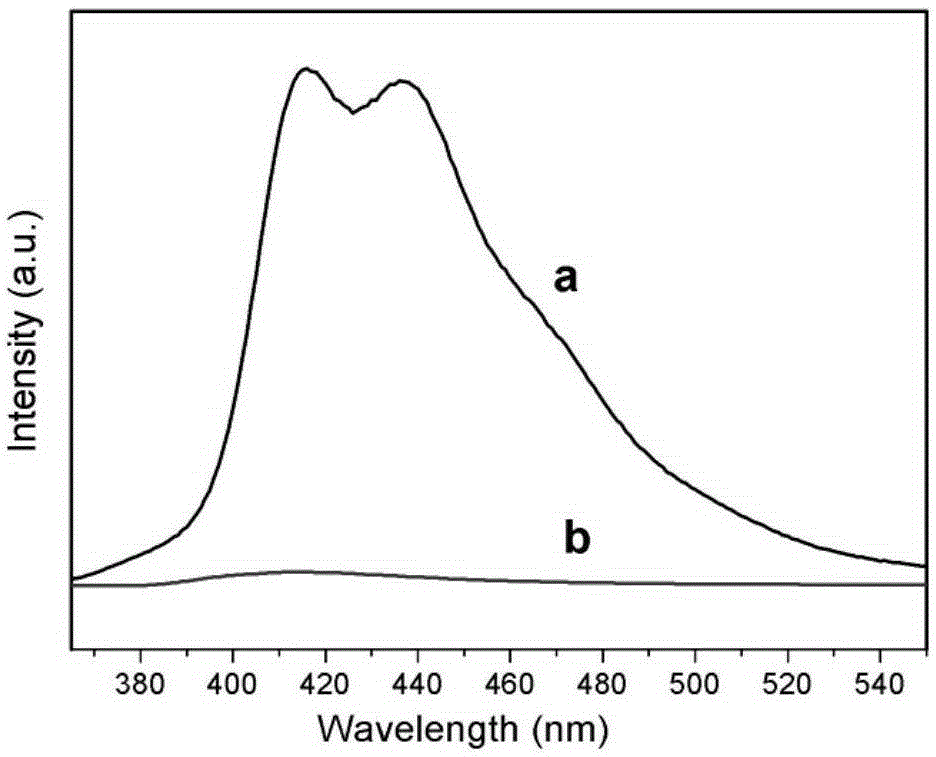

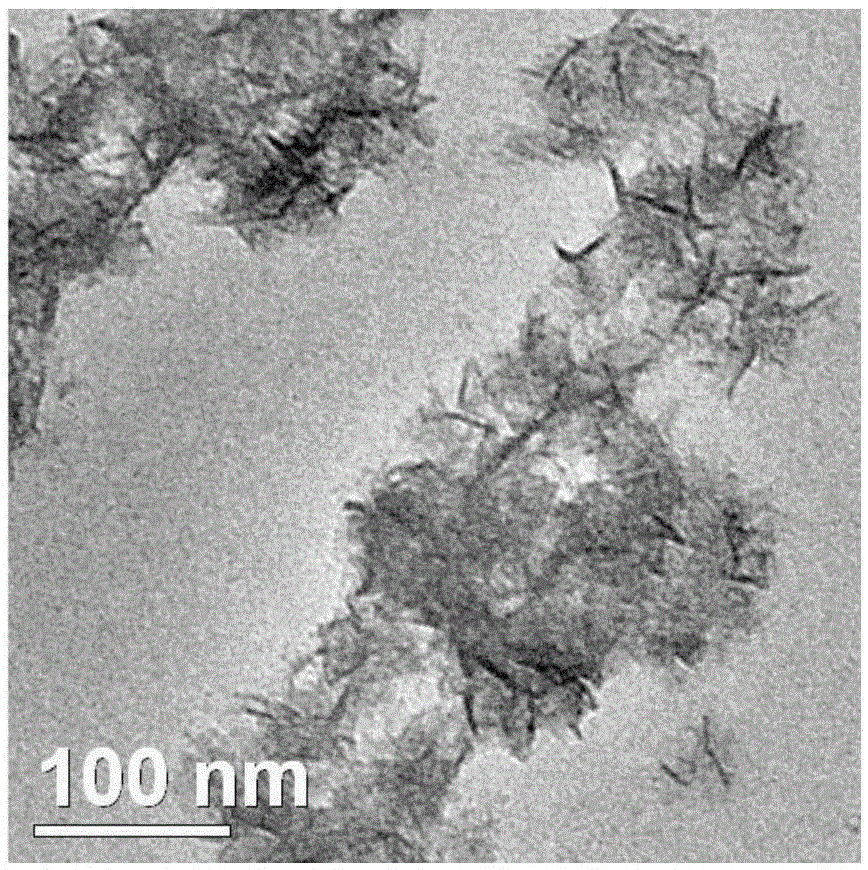

[0034] Weigh a certain amount of Zn(MBT) 2, lay flat on the bottom of the magnetic boat, and then place it in a horizontal vacuum sintering furnace. Under the protection of nitrogen, control the temperature at 550 ° C, heat for 2 hours, and naturally cool to room temperature to obtain white powder (uncoated vulcanized Zinc crystal) is a black solid, which is called a sintered body. The sintered body is dissolved in a dilute hydrochloric acid solution with a volume fraction of 12%, soaked for 30 minutes, and filtered to obtain a black powder. This material is called an acid-treated sample. ...

Embodiment 2

[0040] Weigh 5mmolZnCl 2 Dissolve in 30mL of ethanol, another 10mmol of mercaptoethanol (HMCE) was dissolved in 50mL of ethanol, and then the two solutions were fully mixed to obtain a milky white precipitate Zn(MCE) 2 , after magnetic stirring for 30min, centrifuge washing with ethanol and deionized water for 3 times in turn, collect the milky white precipitate, and dry it in vacuum for 24h to obtain Zn(MCE) 2 .

[0041] Weigh a certain amount of Zn(MCE) 2 , lay flat on the bottom of the magnetic boat, and then place it in a horizontal vacuum sintering furnace. Under the protection of nitrogen, control the temperature at 550 ° C, heat for 2 hours, and naturally cool to room temperature to obtain white powder (uncoated ZnS Crystal) black solid, this substance is called a sintered body, the sintered body is dissolved in a dilute hydrochloric acid solution with a volume fraction of 12%, soaked for 30min, and then filtered to obtain a black powder, which is called an acid-treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com