Cathode additive, preparation method thereof, cathode sheet and lithium battery

A technology of additives and cathode sheets, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electronic conductivity and ion conductivity, harsh humidity and oxygen content, unstable results, etc., and achieve high cycle performance and rate performance, low charge transfer resistance, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Next, the preparation method of the cathode additive according to the second aspect of the present invention is described, which is used to prepare the cathode additive described in the first aspect of the present invention, including the steps of: making lithium-containing compounds, compounds containing M elements, and compounds containing N elements by Li , the molar ratio of M and N is x:a:b dissolved in the solvent, stirred to obtain a uniform mixed solution, then evaporated the solvent and dried to obtain the precursor of the inorganic lithium salt, wherein, 2≤x≤8, 0x m a N b o y ; ultrasonically disperse the inorganic lithium salt particles in a solution containing a conductive agent, evaporate the solvent, and dry to obtain a composite material formed of the inorganic lithium salt and the conductive agent, which is to complete the preparation of the cathode additive.

[0027] In the preparation method of the cathode additive according to the second aspect of th...

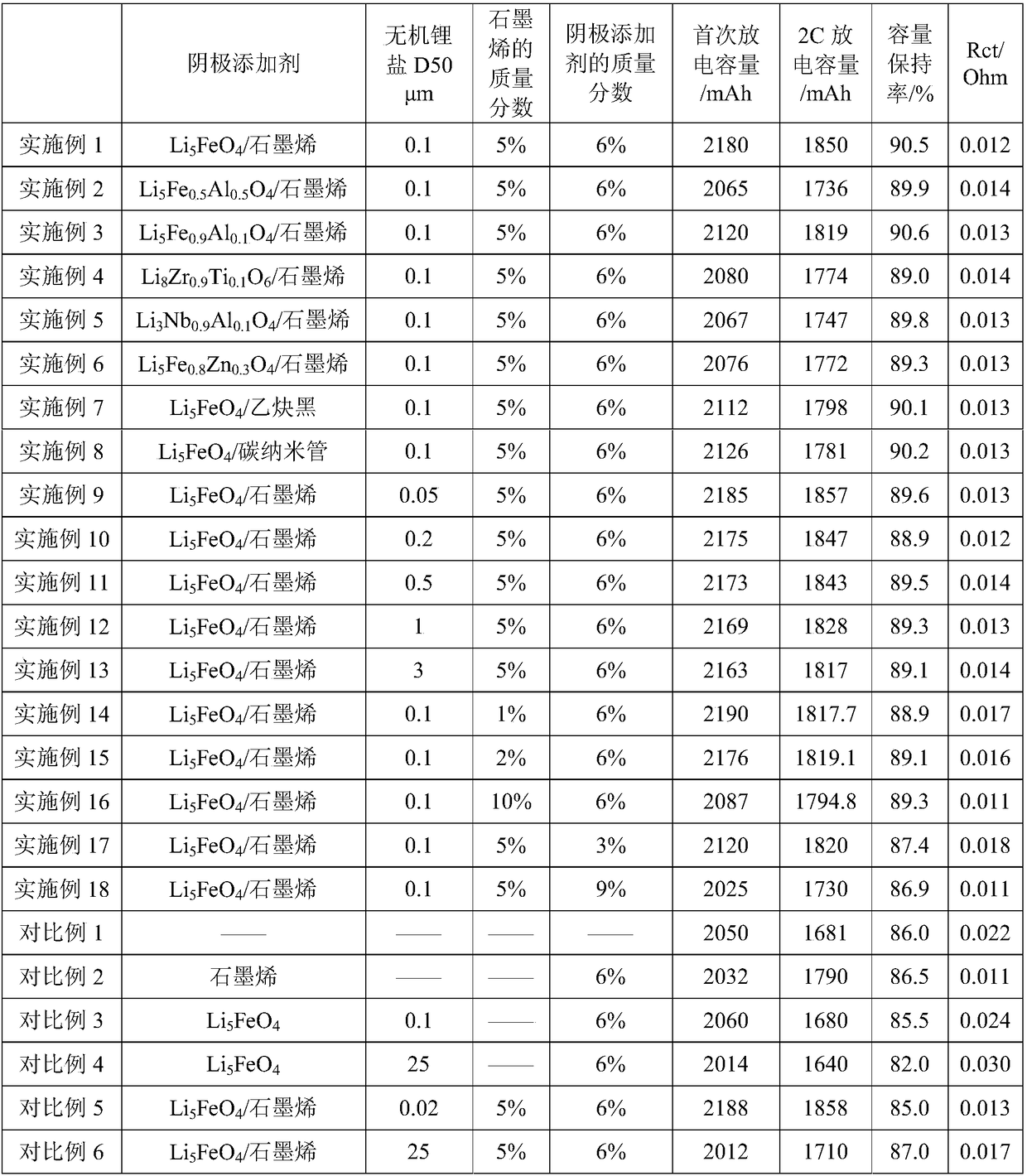

Embodiment 1

[0047] (1) Preparation of cathode additive

[0048] Dissolve the lithium-containing compound lithium acetate and the Fe-containing compound iron nitrate in absolute ethanol at a molar ratio of Li and Fe of 5:1, stir to obtain a uniform mixed solution, heat the above mixed solution while stirring, evaporate the solvent, and dry , to obtain the inorganic lithium salt Li 5 FeO 4 Precursors; Li will be obtained 5 FeO 4 The precursor was calcined twice under a nitrogen atmosphere. The temperature of the first calcination was 550°C for 8 hours, and the temperature of the second calcination was 900°C for 30 hours. After that, it was naturally cooled, ground and sieved, and then The particle size D50 of 0.1 μm Li was obtained by ball milling with a sand mill. 5 FeO 4 Particles; Li 5 FeO 4Particles are ultrasonically dispersed in NMP solution containing conductive agent graphene, the solvent is evaporated and dried to obtain Li 5 FeO 4 / graphene composite material, complete t...

Embodiment 2

[0057] The preparation process of the lithium-ion battery is the same as in Example 1, except that: when preparing the cathode additive, the inorganic lithium salt Li 5 FeO 4 Replaced with Li 5 Fe 0.5 Al 0.5 o 4 , the cathode additive uses Li 5 Fe 0.5 Al 0.5 o 4 / graphene composite, in the cathode membrane, LiCoO 2 , Li 5 Fe 0.5 Al 0.5 o 4 / graphene composite material (Li 5 Fe 0.5 Al 0.5 o 4 The particle size D50 is 0.1 μm, the mass fraction of graphene is 5%), and the mass ratio of Super P and PVDF is 91:6:1.4:1.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Electronic conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com