Preparation method for preparing nano network structure electrode materials of manganese dioxide/conductive polymers applied to super capacitor

A conductive polymer, supercapacitor technology, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve poor conductivity, affect the electrochemical performance and structure of supercapacitors Stability and other issues, to achieve the effect of improving electrical conductivity, conducive to popularization and application, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

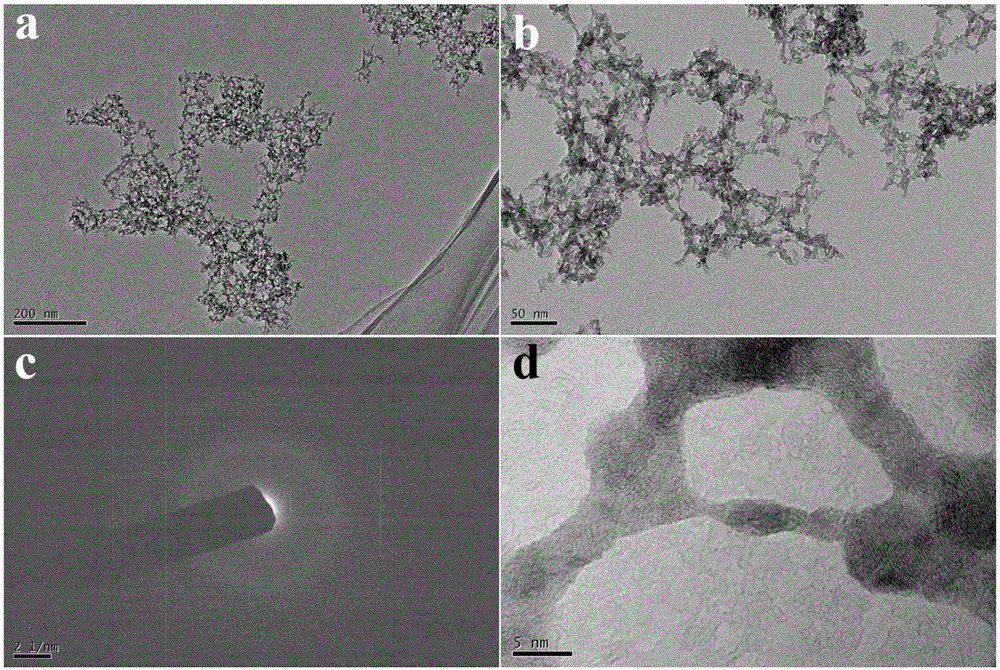

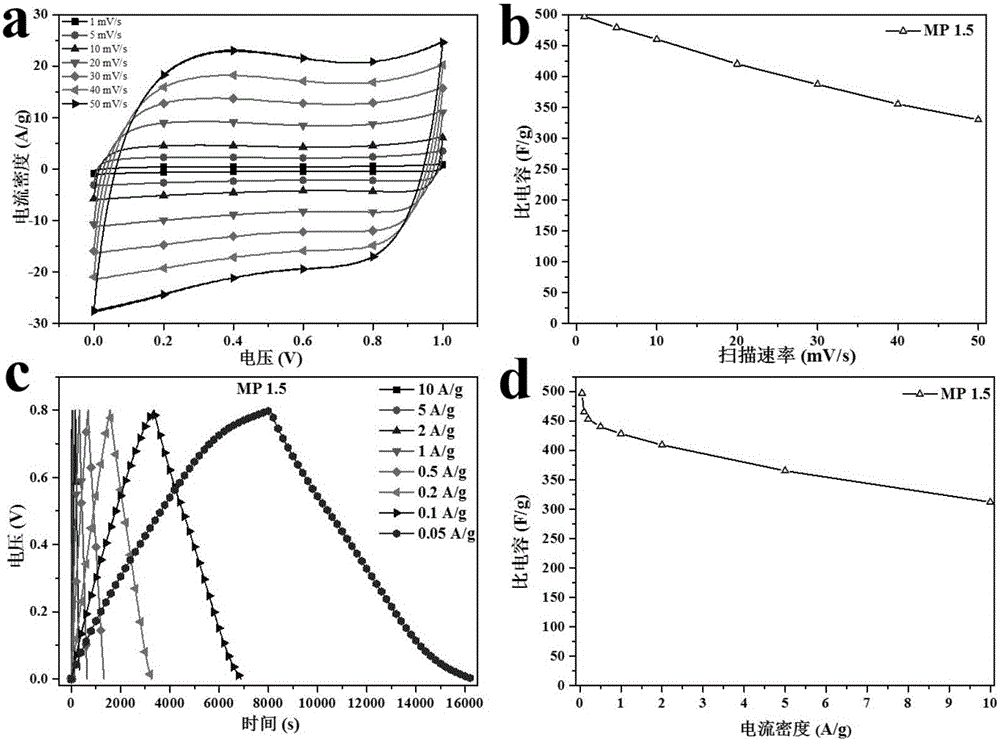

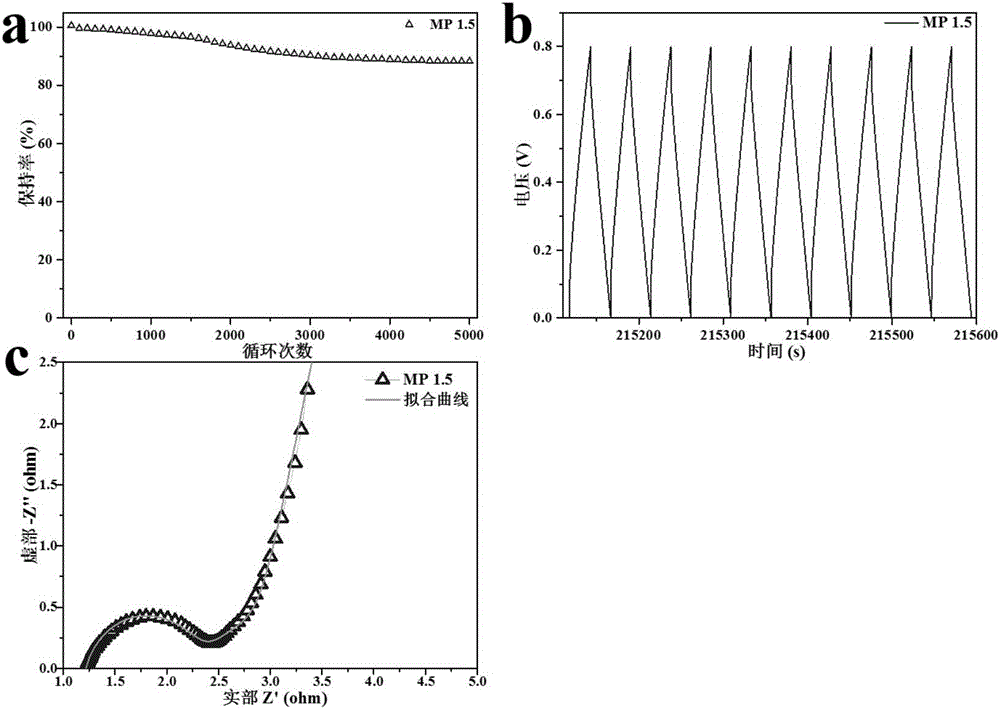

[0022] Weigh 2.08g KMnO 4 , dissolved in 150mL deionized water, and stirred at a certain speed until the solid was completely dissolved to form a transparent and clear solution. According to KMnO 4 Ratio of 1.5wt% of the raw material, weigh the polycarboxylate sodium salt dispersant, and add it to the above KMnO 4 in solution. Measure 0.5ml of aniline monomer solution and slowly add it to KMnO at a speed of 50ul / min 4 In the solution, the stirring rate was maintained at 1000r / min, and the stirring was continued for 1h. The resulting suspension was centrifuged at 8000r / min to achieve solid-liquid separation. Then the obtained solid was washed three times with deionized water and absolute ethanol in sequence, and a solid sample was obtained by separation. Put the solid sample into a 100ml beaker and freeze-dry it at -50°C and 10Pa for 10 hours to obtain the final black powder sample of the manganese dioxide / polyaniline three-dimensional nano-network composite material. The...

Embodiment 2

[0024] Weigh 3.58g KMnO 4 , dissolved in 150mL deionized water, and stirred at a certain speed until the solid was completely dissolved to form a transparent and clear solution. According to KMnO 4 Ratio of 3.2wt% of raw material, weigh cetyltrimethylammonium bromide dispersant, under stirring state, add to above KMnO 4 in solution. Measure 2.0ml of thiophene monomer solution, slowly add to KMnO at a rate of 75ul / min 4 In the solution, the stirring rate was maintained at 500r / min, and the stirring was continued for 4h. The resulting suspension was centrifuged at 5000 r / min to achieve solid-liquid separation. Then the obtained solid was washed three times with deionized water and absolute ethanol in sequence, and a solid sample was obtained by separation. Put the solid sample into a 100ml beaker and freeze-dry at -30°C and 10Pa for 8 hours to obtain the final black powder sample of the manganese dioxide / polythiophene three-dimensional nano-network composite material. The ...

Embodiment 3

[0026]Weigh 5.25g KMnO 4 , dissolved in 150mL deionized water, and stirred at a certain speed until the solid was completely dissolved to form a transparent and clear solution. According to KMnO 4 Ratio of 5.0wt% of raw material, weigh cetyltrimethylammonium bromide dispersant, under stirring state, add to above KMnO 4 in solution. Measure 3.5ml of pyrrole monomer solution, slowly add to KMnO at a rate of 100ul / min 4 In the solution, the stirring rate was maintained at 800r / min, and the stirring was continued for 3h. The resulting suspension was centrifuged at 2000r / min to achieve solid-liquid separation. Then the obtained solid was washed three times with deionized water and absolute ethanol in sequence, and a solid sample was obtained by separation. Put the solid sample into a 100ml beaker and freeze-dry at -80°C and 10Pa for 12 hours to obtain the final black powder sample of the manganese dioxide / polypyrrole three-dimensional nano-network composite. The measured powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com