Lithium ion battery graphite negative electrode material and preparation method thereof

A lithium-ion battery, graphite negative electrode technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem that low temperature performance needs to be further improved, and achieve the effect of reducing charge transfer resistance, shortening transmission distance, and accelerating diffusion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

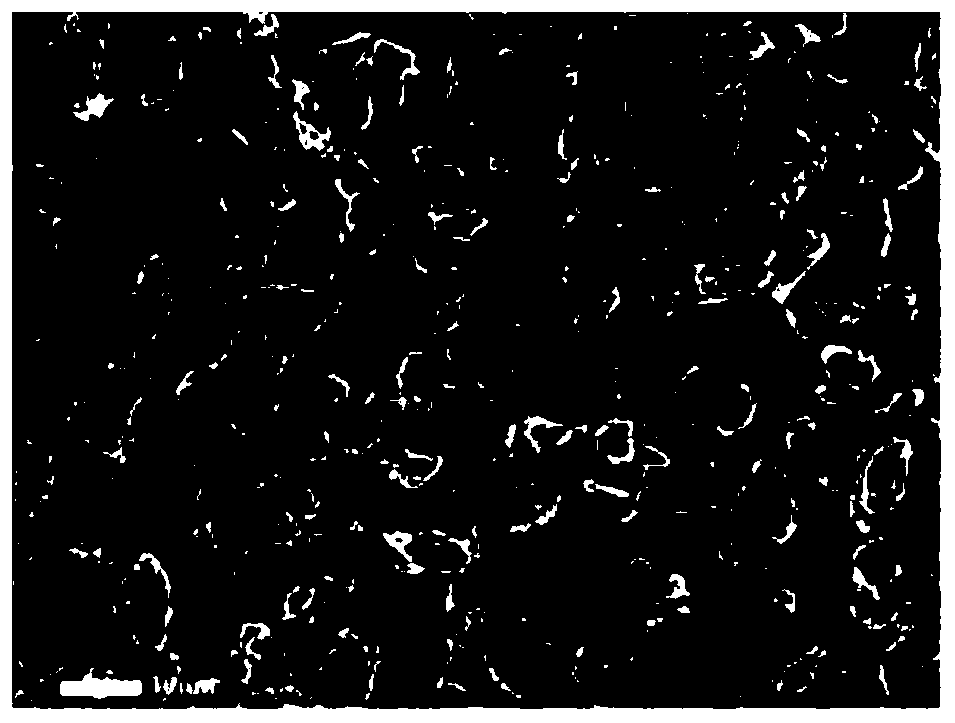

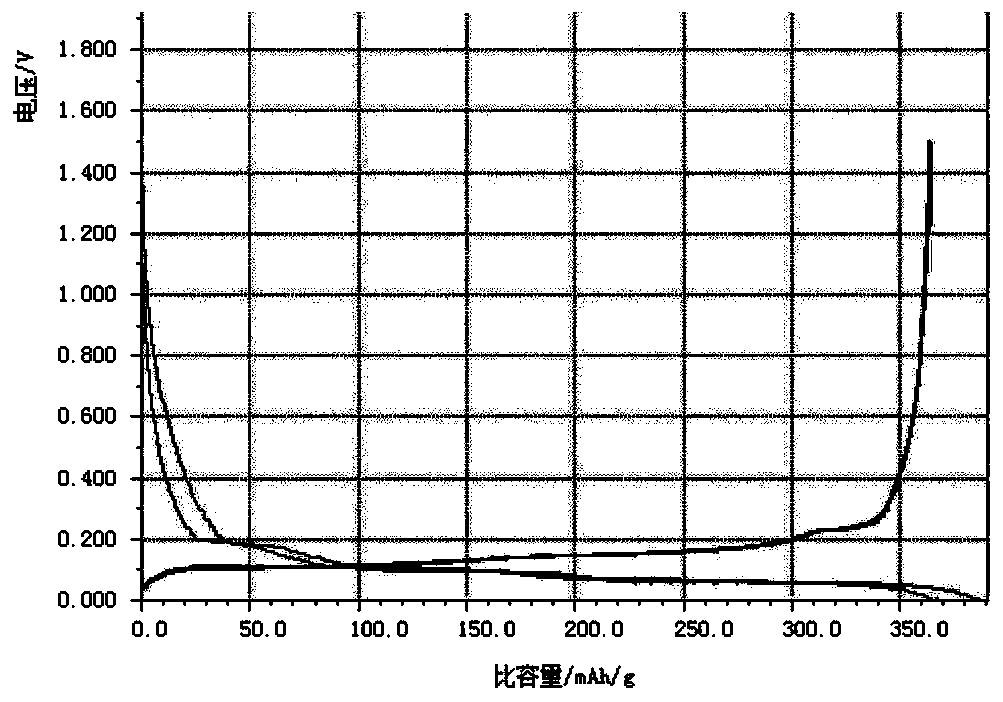

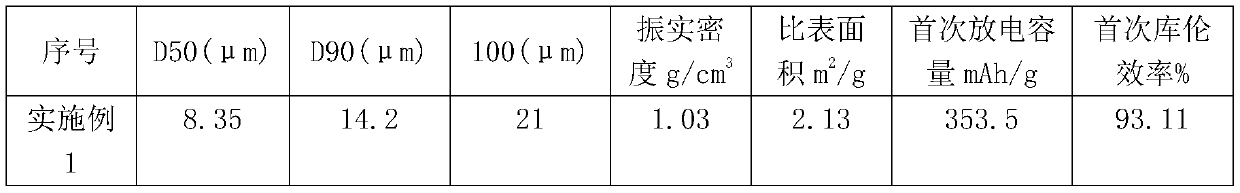

[0037] The needle coke raw material is crushed and shaped by a pulverizer and a shaping machine. After shaping, the particle size D50 is 3.5 μm, D90 is 8.1 μm, and D100 is 17.2 μm. Weigh 10 kg of needle coke shaping raw material and 22 g of copper powder , 10g of nano-conductive carbon and 900g of high-temperature pitch. After fully mixing the three materials, put them into the bedroom reactor, heat the reactor to 550°C, keep it warm for 3 hours, and take it out after it cools down to room temperature. Take 300g of phenolic resin and fully mix it with the material from the reactor, then heat it at 1200°C for 3 hours for high-temperature coating, and finally hold it at 3000°C for 12 hours for graphitization treatment to obtain a lithium-ion battery with excellent low temperature and rate performance Graphite anode material.

Embodiment 2

[0039] The needle coke raw material is pulverized and shaped by a pulverizer and a shaping machine. After shaping, the particle size D50 is 4.1 μm, D90 is 8.6 μm, and D100 is 16.8 μm. Weigh 10 kg of needle coke shaping raw material and 50 g of copper powder , 10g of nano-conductive carbon and 930g of high-temperature pitch. After fully mixing the three materials, put them into the bedroom reactor, heat the reactor to 550°C, keep it warm for 3 hours, and take it out after it cools down to room temperature. Take 280g of phenolic resin and fully mix it with the material from the reactor, then heat it at 1200°C for 3 hours for high-temperature coating, and finally hold it at 3000°C for 12 hours for graphitization treatment to obtain a lithium-ion battery with excellent low temperature and rate performance Graphite anode material.

Embodiment 3

[0041]The needle coke raw material is crushed and shaped by a pulverizer and a shaping machine. After shaping, the particle size D50 is 4.5 μm, D90 is 9.2 μm, and D100 is 18.5 μm. Weigh 10 kg of needle coke shaping raw material and 18 g of copper powder , 2.5g of nano-conductive carbon and 480g of high-temperature pitch. After fully mixing the three materials, put them into the bedroom reactor, heat the reactor to 550°C, keep it warm for 3 hours, and take it out after it cools down to room temperature. Take 450g of phenolic resin and fully mix it with the material from the reactor, then heat it at 1200°C for 3 hours for high-temperature coating, and finally heat it at 3000°C for 12 hours for graphitization treatment to obtain a lithium-ion battery with excellent low temperature and rate performance Graphite anode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com