Yttrium oxide powder and preparation method thereof

A technology of yttrium oxide and powder, which is applied in the field of yttrium oxide powder and its preparation, can solve the problems of inability and small contact surface of alloy, and achieve the effects of wide application, strong binding ability and fine grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the present embodiment yttrium oxide powder comprises the following steps:

[0030] 1) Weigh 5 g of yttrium nitrate hexahydrate, add 10 mL of glycerol, and then add 45 mL of deionized water to obtain solution A, drop ammonia water into solution A to adjust pH=8, and obtain mixed solution B;

[0031] 2) Put the mixed solution B obtained in step 1) into a 100mL polytetrafluoroethylene-lined autoclave, react in an oven at 170°C for 15h, vacuum filter the precipitate obtained from the reaction, and wash it with deionized water for 5 h Second, vacuum-dry at 60°C for 4 hours in a drying oven to obtain the precursor powder;

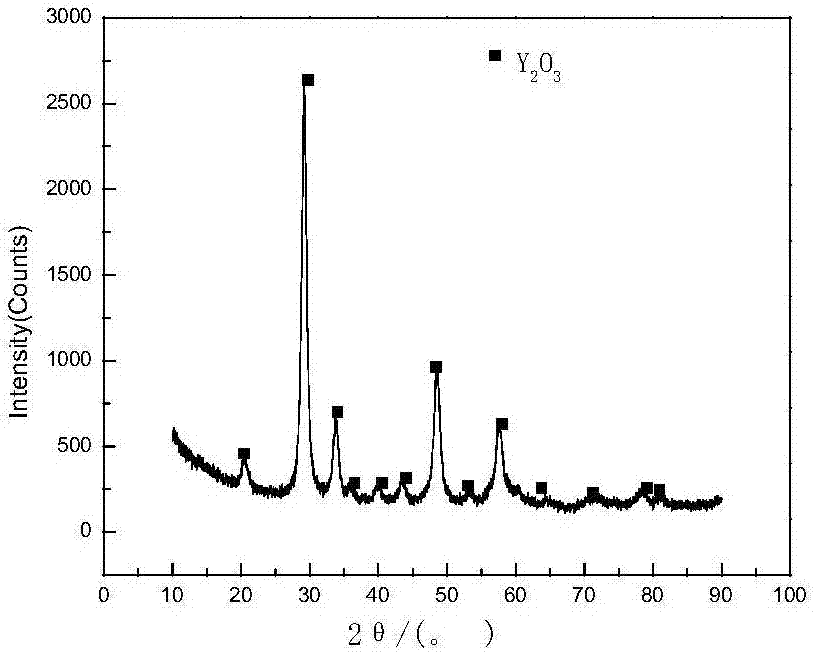

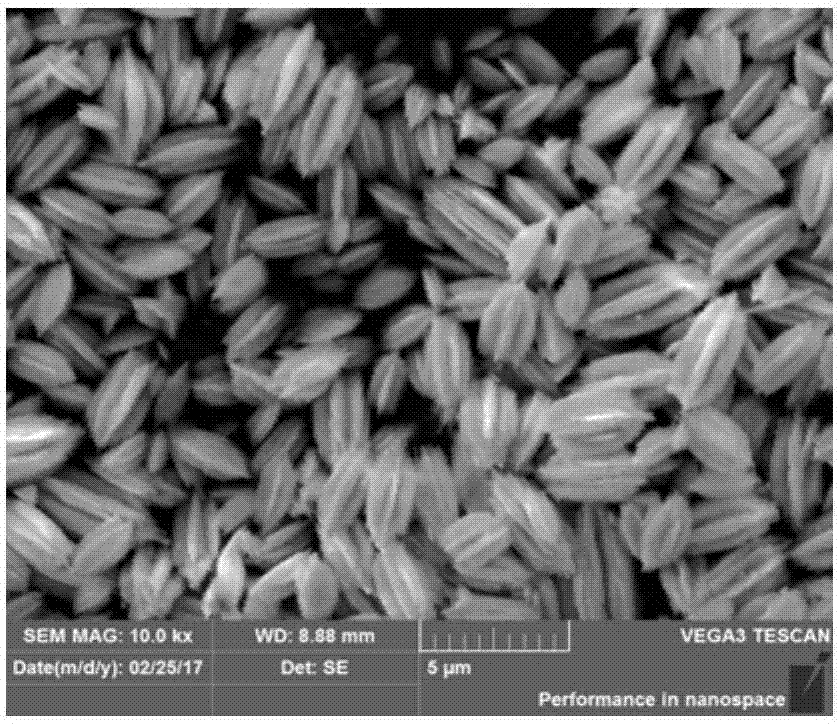

[0032] 3) The precursor powder obtained in step 2) was ground, then calcined in a muffle furnace at 600° C. for 3 h, and air-cooled to room temperature to obtain carambola-like yttrium oxide powder.

Embodiment 2

[0034] The preparation method of the present embodiment yttrium oxide powder comprises the following steps:

[0035] 1) Weigh 5 g of yttrium nitrate hexahydrate, add 15 mL of glycerol, and then add 40 mL of deionized water to obtain solution A, drop ammonia water into solution A to adjust the pH to 9, and obtain mixed solution B;

[0036] 2) Put the mixed solution B obtained in step 1) into a 100mL polytetrafluoroethylene-lined autoclave, react in an oven at 160°C for 14h, vacuum filter the precipitate obtained from the reaction, wash it with deionized water for 5 Second, dry in vacuum at 70°C for 5 hours in a drying oven to obtain precursor powder;

[0037] 3) The precursor powder obtained in step 2) was ground, then calcined in a muffle furnace at 700° C. for 2 h, and air-cooled to room temperature to obtain carambola-like yttrium oxide powder.

Embodiment 3

[0039] The preparation method of the present embodiment yttrium oxide powder comprises the following steps:

[0040] 1) Weigh 5 g of yttrium nitrate hexahydrate, add 12 mL of glycerol, and then add 42 mL of deionized water to obtain solution A, drop ammonia water into solution A to adjust pH=10, and obtain mixed solution B;

[0041] 2) Put the mixed solution B obtained in step 1) into a 100mL polytetrafluoroethylene-lined autoclave, react in an oven at 170°C for 16h, vacuum filter the precipitate obtained from the reaction, and wash it with deionized water for 6 hours. Second, vacuum-dry at 60°C for 4 hours in a drying oven to obtain the precursor powder;

[0042] 3) The precursor powder obtained in step 2) was ground, then calcined in a muffle furnace at 600° C. for 2 h, and air-cooled to room temperature to obtain carambola-shaped yttrium oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com