Graphitized active carbon-based composite additive, preparation method and applications thereof

A composite additive and activated carbon technology, applied in the direction of lead-acid battery electrodes, battery electrodes, hybrid capacitor electrodes, etc., can solve the problem that the electronic conduction ability of activated carbon particles cannot be changed, so as to improve speed and reversibility, reduce internal resistance, and prevent The effect of sulfation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

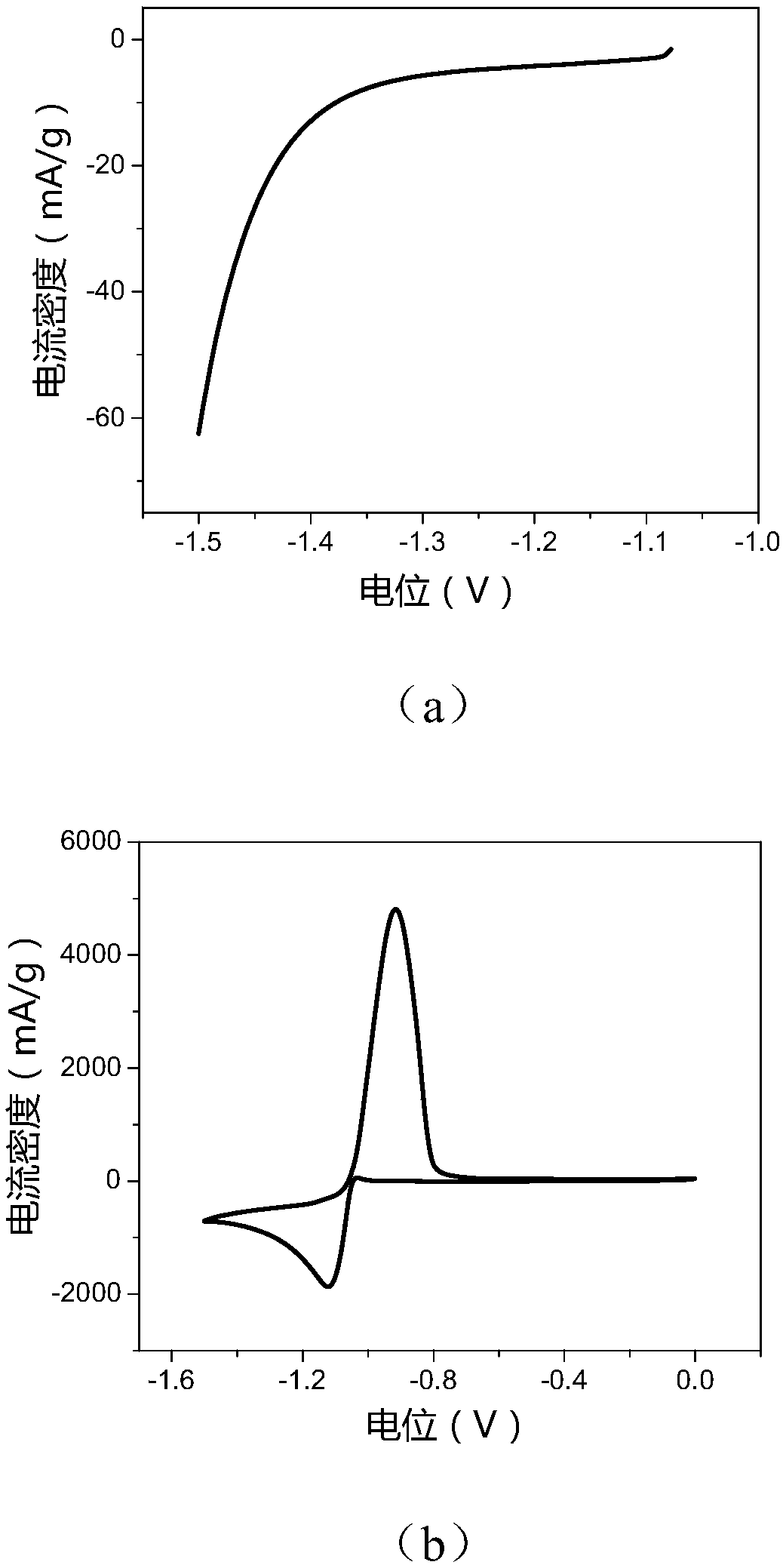

Embodiment 1

[0048] Weigh 0.2 g of analytically pure nickel nitrate, add it to 10 mL of deionized water, and fully stir until completely dissolved to obtain a nickel nitrate solution. Weigh 0.2816 g of analytically pure disodium ethylenediaminetetraacetic acid (EDTA), add it to 20 mL of deionized water, and stir well until it is completely dissolved to obtain an EDTA solution. The prepared nickel nitrate solution was added to the EDTA solution and stirred for 30 min to make the nickel ions fully complexed by EDTA. Then 10g of activated carbon was added to the above solution, stirred for 30min, the obtained slurry was dried at 85°C for 20h, and the powder obtained by drying was dried in N 2 The partially graphitized activated carbon was obtained by calcining at 800 °C for 2 h in a protective atmosphere. Take 1.5g of partially graphitized activated carbon, add it to 150ml of dilute nitric acid solution with a concentration of 1mol / L, stir for 16h, and carry out pickling. After the stirring...

Embodiment 2

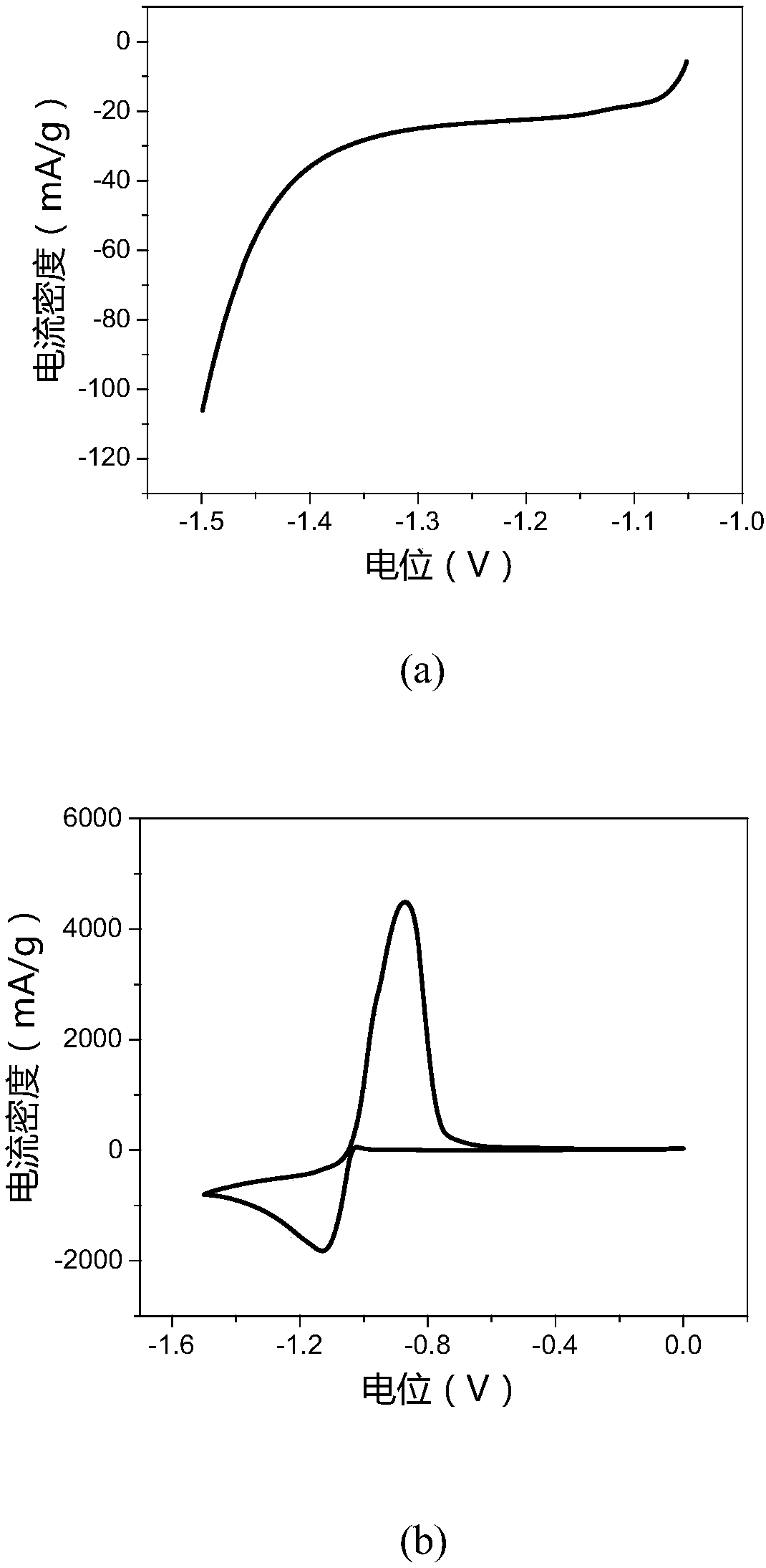

[0050] Weigh 0.2 g of analytically pure nickel nitrate, add it to 10 mL of deionized water, and fully stir until completely dissolved to obtain a nickel nitrate solution. Weigh 0.2816 g of analytically pure disodium ethylenediaminetetraacetic acid (EDTA), add it to 20 mL of deionized water, and stir well until it is completely dissolved to obtain an EDTA solution. The prepared nickel nitrate solution was added to the EDTA solution and stirred for 30 min to make the nickel ions fully complexed by EDTA. Then 10g of activated carbon was added to the above solution, stirred for 30min, the obtained slurry was dried at 85°C for 20h, and the powder obtained by drying was dried in N 2 The partially graphitized activated carbon was obtained by calcining at 900 °C for 2 h in a protective atmosphere. Take 1.5g part of graphitized activated carbon, add it to 150ml of dilute nitric acid solution with a concentration of 1mol / L, stir for 16h, and carry out acid washing. The pH value reache...

Embodiment 3

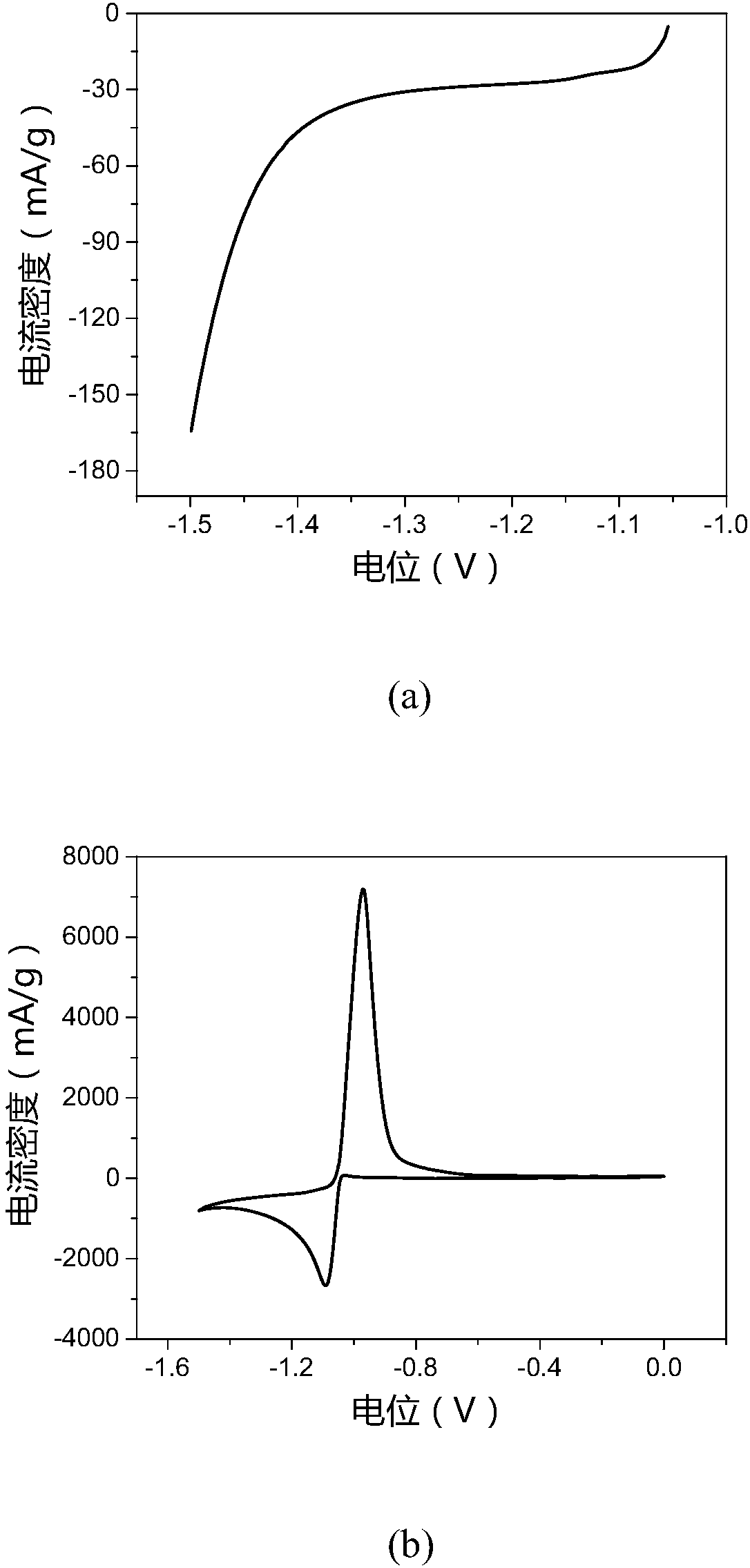

[0052] Weigh 0.2 g of analytically pure nickel nitrate, add it to 10 mL of deionized water, and fully stir until completely dissolved to obtain a nickel nitrate solution. Weigh 0.2816 g of analytically pure disodium ethylenediaminetetraacetic acid (EDTA), add it to 20 mL of deionized water, and stir well until it is completely dissolved to obtain an EDTA solution. The prepared nickel nitrate solution was added to the EDTA solution and stirred for 30 min to make the nickel ions fully complexed by EDTA. Then 10g of activated carbon was added to the above solution, stirred for 30min, the obtained slurry was dried at 85°C for 20h, and the powder obtained by drying was dried in N 2 The partially graphitized activated carbon was obtained by calcining at 800 °C for 5 h in a protective atmosphere. Take 1.5g part of graphitized activated carbon, add it to 150ml of dilute nitric acid solution with a concentration of 1mol / L, stir for 16h, and carry out acid washing. The pH value reache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com