Preparation method for active carbon loaded tungsten carbide nanometer composite powder used as electrocatalyst

A tungsten carbide nano-composite powder technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high cost and long preparation time, and achieve low cost and high specific surface area , the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

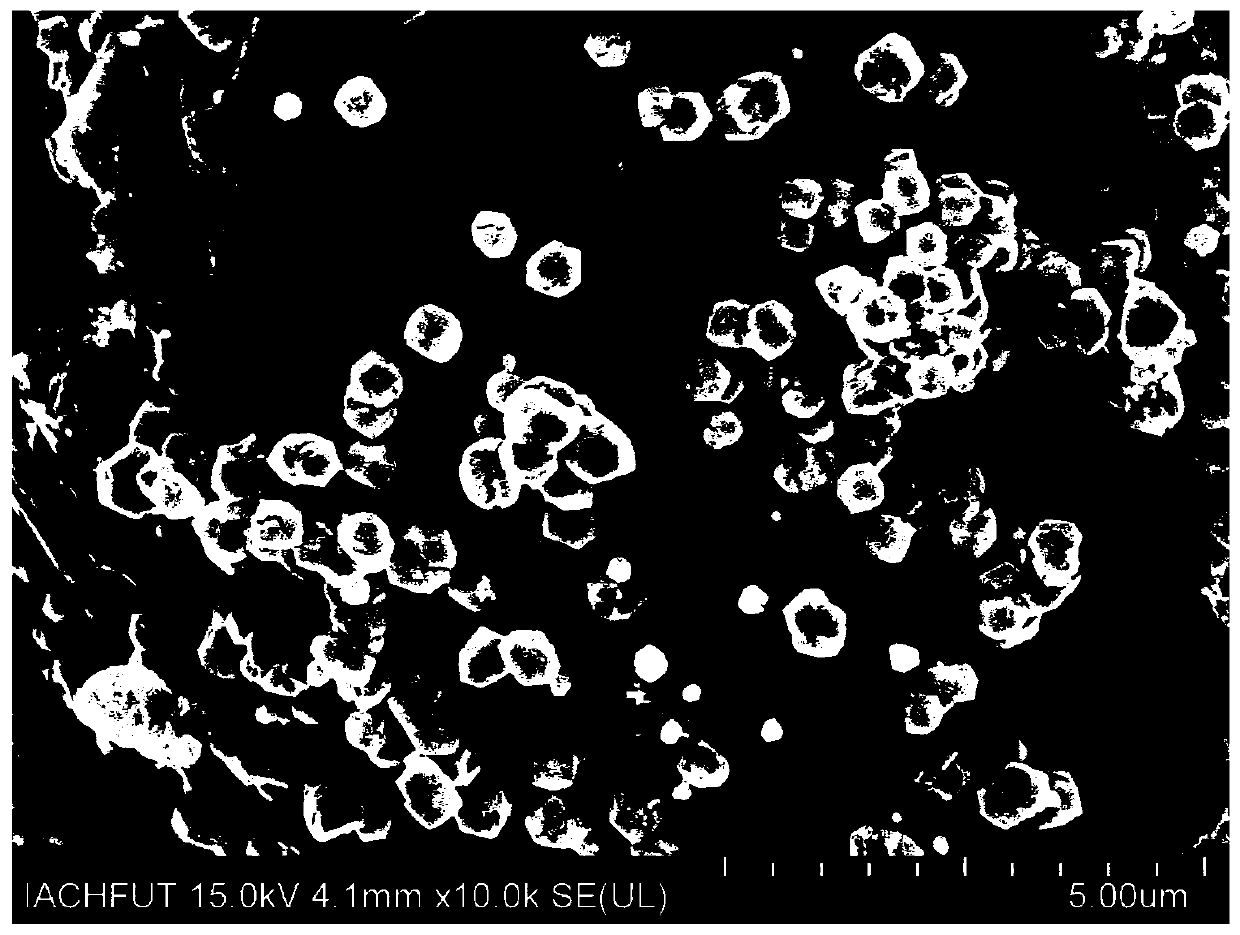

[0032] (1) Activated carbon is ball-milled and passed through a 200-mesh sieve; the sieved activated carbon is placed in nitric acid with a concentration of 1mol / L, and activated for 4 hours in an oil bath at 85°C, filtered after cooling, and washed until neutral, 120 Dry at ℃ for 5h to obtain activated carbon.

[0033] (2) Take ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, activated carbon 12g, ammonium nitrate (NH 4 NO 3 ) 0.24mol, ethylenediaminetetraacetic acid 0.0072mol, and glycine 0.072mol; each raw material powder was dissolved in 50mL deionized water, and magnetically stirred for 8 hours at room temperature to obtain a mixed solution;

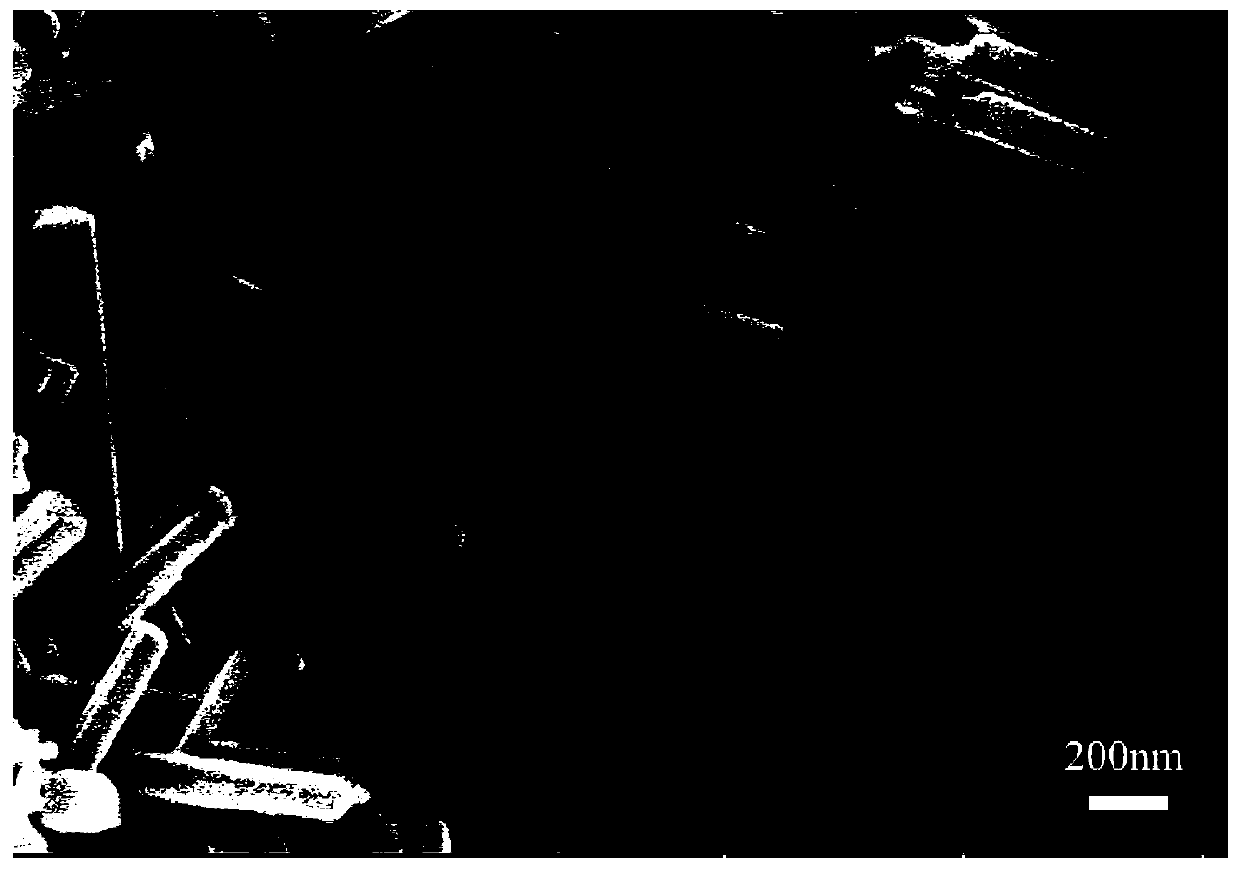

[0034] (3) Heating the mixed solution in a muffle furnace at a constant temperature of 200°C for 3 hours to obtain a porous nanoacicular activated carbon-supported violet tungsten precursor powder;

[0035] (4) Place the precursor powder in a tube furnace, and carbonize it at 850°C for 4h in a mixed atmosphere of met...

Embodiment 2

[0038] (1) Activated carbon is ball milled and passed through a 250-mesh sieve; the sieved activated carbon is placed in nitric acid with a concentration of 1 mol / L, and activated for 4 hours in an oil bath at 85°C, filtered after cooling, and washed until neutral, 120 Dry at ℃ for 5h to obtain activated carbon.

[0039] (2) Take ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, activated carbon 4g, ammonium nitrate (NH 4 NO 3 ) 0.24mol, ethylenediaminetetraacetic acid 0.0072mol, and glycine 0.072mol; each raw material powder was dissolved in 50mL deionized water, and magnetically stirred for 8 hours at room temperature to obtain a mixed solution;

[0040] (3) Heating the mixed solution in a muffle furnace at a constant temperature of 200°C for 3 hours to obtain a porous nanoacicular activated carbon-supported violet tungsten precursor powder;

[0041] (4) Place the precursor powder in a tube furnace, and carbonize it at 800°C for 4h in a mixed atmosphere of met...

Embodiment 3

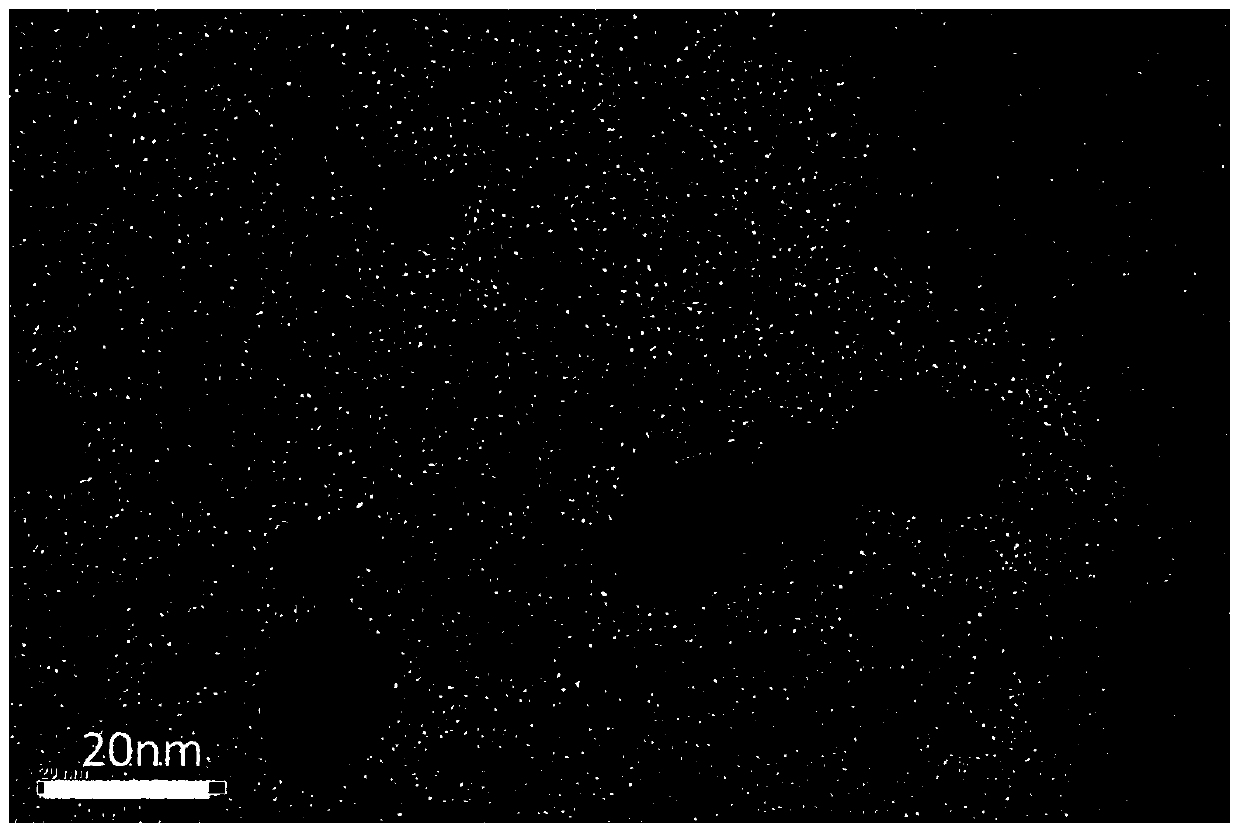

[0044] (1) Activated carbon is ball milled and passed through a 400-mesh sieve; the sieved activated carbon is placed in nitric acid with a concentration of 1mol / L, and activated for 4 hours in an oil bath at 85°C, filtered after cooling, and washed until neutral, 120 Dry at ℃ for 5h to obtain activated carbon.

[0045] (2) Take ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, activated carbon 3g, ammonium nitrate (NH 4 NO 3 ) 0.24mol, ethylenediaminetetraacetic acid 0.0072mol, citric acid 0.1mol; each raw material powder was dissolved in 50mL deionized water, and magnetically stirred at room temperature for 8h to obtain a mixed solution;

[0046] (3) Heating the mixed solution in a muffle furnace at a constant temperature of 200°C for 3 hours to obtain a porous nanoacicular activated carbon-supported violet tungsten precursor powder;

[0047] (4) Place the precursor powder in a tube furnace, and carbonize it at 800°C for 3h in a mixed atmosphere of methane and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com