Pyramid rapid texturing solution and texturing method and silicon wafer product thereof

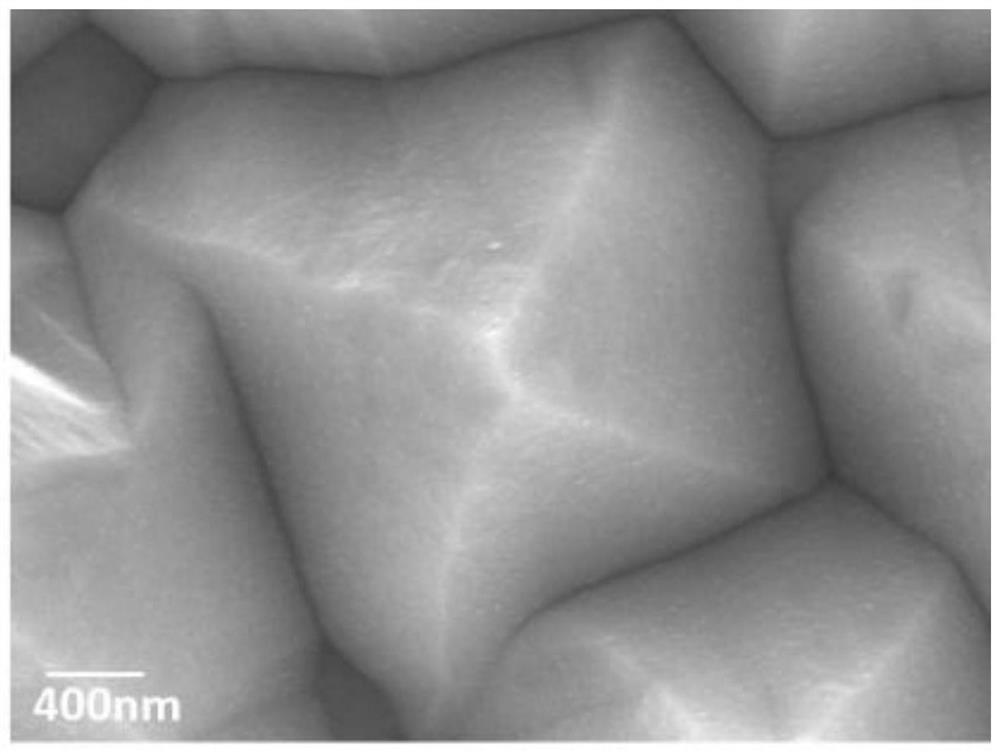

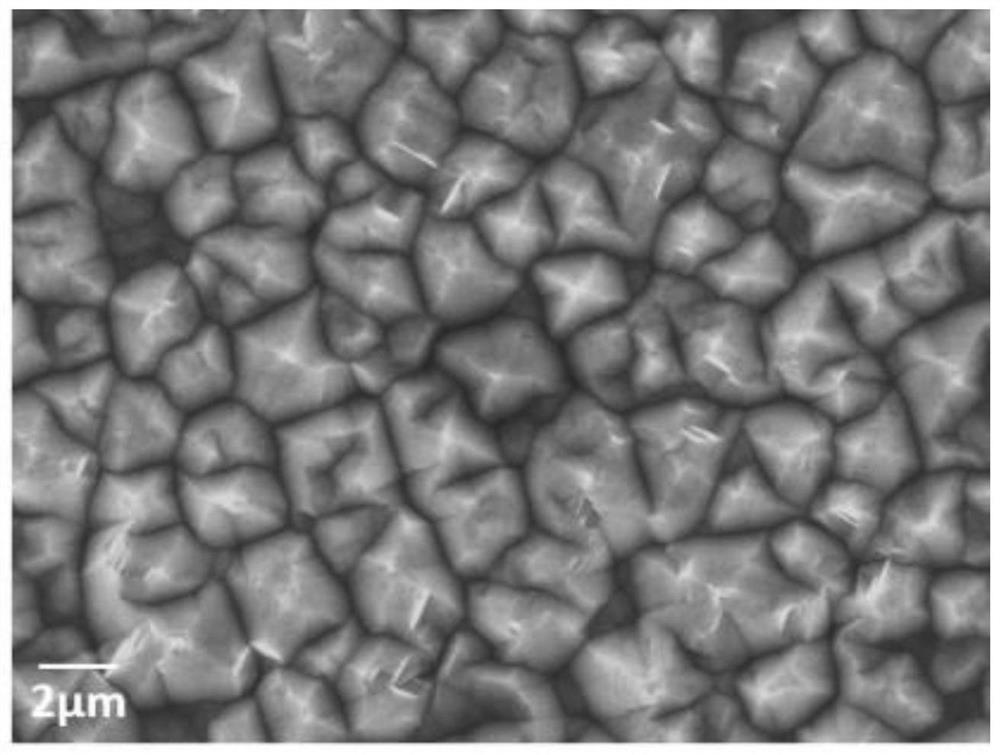

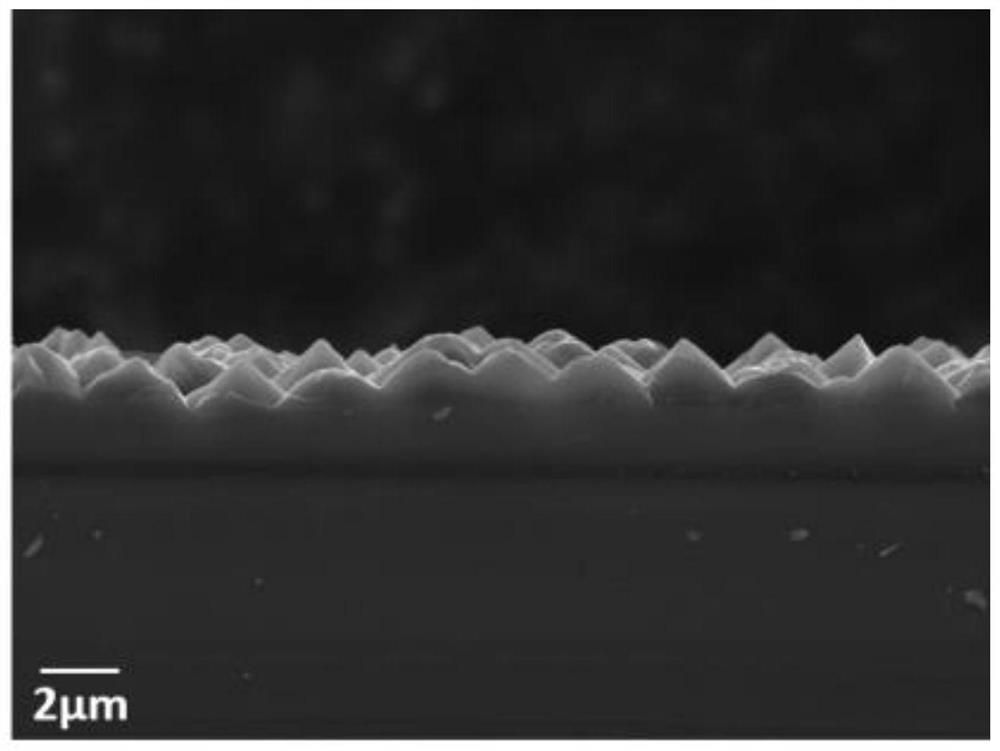

A pyramid and texturing liquid technology, applied in the field of solar cells, can solve the problems of affecting the efficiency of the cells, requiring high temperature, loss of optical properties, etc., and achieves the effect of uniform structure distribution, uniformity, and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Silicon wafer pre-cleaning

[0053] Soak the silicon chip in a mixed solution of lye and hydrogen peroxide at a temperature of 45-60°C for 120s, and then wash it with water for 120s; put the washed silicon chip in a dilute acid solution and soak it for 120s at room temperature ; Then wash with water, the washing time is 180s.

[0054] 2) Texturing

[0055] Put the pre-cleaned and water-washed silicon wafers in step 1) into the pyramid rapid texturing solution, the pyramid rapid texturing solution is composed of silver nitrate, copper nitrate, hydrofluoric acid, hydrogen peroxide and deionized water. Wherein, the concentration of silver nitrate is 0.01mmol / L, the concentration of copper nitrate is 100mmol / L, the concentration of hydrofluoric acid is 4.8mol / L; The concentration of hydrogen peroxide is 3.6mol / L; Reaction temperature is 30 ℃, reaction time is 240s.

[0056] 3) After cleaning

[0057] Take out the textured silicon wafer in step 2), place it in nitric ...

Embodiment 2

[0059] 1) Silicon wafer pre-cleaning

[0060] The silicon wafer pre-cleaning step in this embodiment is basically the same as the step 1) silicon wafer pre-cleaning step in Embodiment 1, and will not be repeated here.

[0061] 2) Texturing

[0062] Put the pre-cleaned and water-washed silicon wafers in step 1) into the pyramid rapid texturing solution, the pyramid rapid texturing solution is composed of silver nitrate, copper nitrate, hydrofluoric acid, hydrogen peroxide and deionized water. Wherein, the concentration of silver nitrate is 0.001mmol / L, the concentration of copper nitrate is 100mmol / L, the concentration of hydrofluoric acid is 7.0mol / L; the concentration of hydrogen peroxide is 1.3mol / L; the reaction temperature is 30 ℃, and the reaction time is 240s.

[0063] 3) After cleaning

[0064] The post-cleaning step of the silicon wafer in this embodiment is basically the same as the post-cleaning step in step 3) in Embodiment 1, and will not be repeated here.

[0...

Embodiment 3

[0067] 1) Silicon wafer pre-cleaning

[0068] The silicon wafer pre-cleaning step in this embodiment is basically the same as the step 1) silicon wafer pre-cleaning step in Embodiment 1, and will not be repeated here.

[0069] 2) Texturing

[0070] Put the pre-cleaned and water-washed silicon wafers in step 1) into the pyramid rapid texturing solution, the pyramid rapid texturing solution is composed of silver nitrate, copper nitrate, hydrofluoric acid, hydrogen peroxide and deionized water. Wherein, the concentration of silver nitrate is 0.1mmol / L, the concentration of copper nitrate is 150mmol / L, the concentration of hydrofluoric acid is 4.8mol / L; The concentration of hydrogen peroxide is 5.0mol / L; Reaction temperature is 30 ℃, reaction time is 240s.

[0071] 3) After cleaning

[0072] The post-cleaning step of the silicon wafer in this embodiment is basically the same as the post-cleaning step in step 3) in Embodiment 1, and will not be repeated here.

[0073] Compared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com