Phosphate positive electrode material and preparation method and application thereof

A cathode material, phosphate technology, applied in the field of phosphate cathode material and its preparation, can solve the problems of large amount of metal vanadium, poor conductivity, cumbersome process, etc., and achieves the improvement of conductivity, rate performance, and discharge voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a phosphate cathode material, and the specific preparation steps are as follows:

[0064] Add manganese acetate, vanadium acetylacetonate, aluminum isopropoxide, sodium acetate and phosphoric acid with a molar composition ratio of 1:0.8:0.2:4:3 to the ethanol solution containing citric acid, wherein the substance of citric acid and aluminum isopropoxide The volume ratio is 2:1. Then the mixed solution was placed in a water bath at 100°C with magnetic stirring until the ethanol evaporated completely. Grind the obtained precursor to a powder state, place it in a tube furnace with an argon atmosphere and sinter at 800 °C for 12 h to obtain Na 4 V 0.8 al0.2 Mn(PO 4 ) 3 Cathode material.

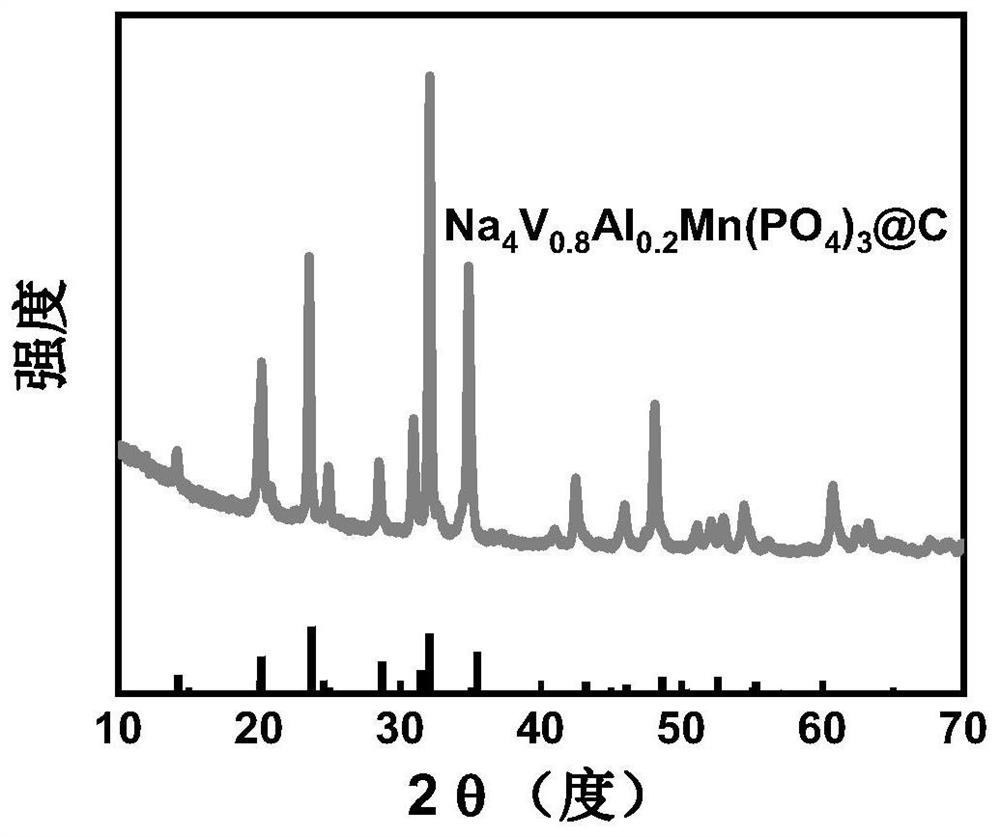

[0065] The Na coated with carbon coating layer 4 V 0.8 Al 0.2 Mn(PO 4 ) 3 The XRD pattern of the positive electrode material is as follows figure 1 shown by figure 1 It can be seen that the diffraction peaks of the prepared material correspond to the st...

Embodiment 2

[0072] This embodiment provides a kind of preparation steps of phosphate cathode material as follows:

[0073] Add manganese acetate, ammonium metavanadate, magnesium acetate, sodium carbonate and phosphoric acid with a composition ratio of 1:0.9:0.1:4.1:3 to the solution containing glucose, wherein the substance ratio of the total content of glucose and metal ions is 1.5: 1. Then the mixed solution was placed in a water bath at 120° C. and magnetically stirred until the water evaporated completely. Grind the obtained precursor to a powder state, place it in a tube furnace with an argon atmosphere and sinter at 700°C for 10 hours to obtain a carbon-coated Na 4.1 V 0.9 Mg 0.1 Mn(PO 4 ) 3 Cathode material.

[0074] The Na coated with carbon coating layer 4.1 V 0.9 Mg 0.1 Mn(PO 4 ) 3 The first charge and discharge curve of the positive electrode material at 0.2C is as follows: Figure 7 shown.

Embodiment 3

[0076] This embodiment provides a kind of preparation steps of phosphate cathode material as follows:

[0077] Add manganese acetate, vanadium acetylacetonate, ferrous acetylacetonate, sodium carbonate and ammonium dihydrogen phosphate with a composition ratio of 1:0.6:0.4:0.2:4.4:3 to the solution containing citric acid, wherein the total of citric acid and transition metal The quantity ratio of quantity to substance is 1.2:1. Then the mixed solution was placed in a water bath at 110°C with magnetic stirring until the water evaporated completely. Grind the obtained precursor to a powder state, place it in a tube furnace with an argon atmosphere and sinter at 650°C for 10 hours to obtain a carbon-coated Na 4.4 V 0.6 Fe 0.4 Mn(PO 4 ) 3 Cathode material.

[0078] The Na coated with carbon coating layer 4.4 V 0.6 Fe 0.4 Mn(PO 4 ) 3 The first charge and discharge curve of the positive electrode material at 0.2C is as follows: Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com