Method for preparing black titanium dioxide powder by pulse laser sputtering deposition under negative-pressure environment

A black titanium dioxide, pulsed laser sputtering technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide and other directions, can solve the problems of low preparation efficiency, complex preparation method of black titanium dioxide, etc., achieve simple operation, widen light Response range, risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

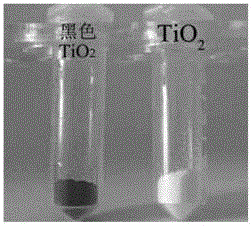

[0018] Embodiment 1: the preparation of black titanium dioxide powder, step is:

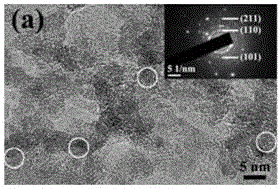

[0019] Use a tablet press to press the purchased anatase-type white titanium dioxide into a circular target with a diameter of 2 cm and a thickness of 2 mm, with a pressure of 200 MPa; place the circular target in a vacuum tank, and vacuumize the vacuum tank. The internal pressure is 1×10 3 Pa; adjust the angle between the incident laser beam of the pulse laser and the circular target to be 10°, the substrate of the pulse laser is selected as a high temperature resistant quartz substrate or K9 glass substrate, adjust the substrate base and the circular target The distance between the materials is 25mm to ensure that the product can be deposited on the substrate by sputtering; turn on the pulse laser, adjust the laser pulse width of the pulse laser to 8ns, the wavelength to 1064nm, the energy to 950mJ, and the frequency to 10Hz; the laser focus is 2mm in diameter The light spot irradiates the whi...

Embodiment 2

[0021] Embodiment 2: the preparation of black titanium dioxide powder, step is:

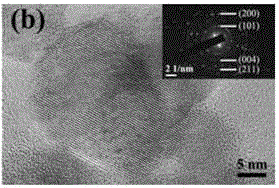

[0022] Use a tablet press to press the purchased anatase-type white titanium dioxide into a circular target with a diameter of 2 cm and a thickness of 1 mm, with a pressure of 160 MPa; place the circular target in a vacuum tank, and vacuumize the vacuum tank. The internal pressure is 1×10 -3 Pa; adjust the angle between the incident laser beam of the pulse laser and the circular target to be 45°, the substrate of the pulse laser is selected as a high temperature resistant quartz substrate or K9 glass substrate, adjust the substrate base and the circular target The distance between the materials is 40mm to ensure that the product can be deposited on the substrate by sputtering; turn on the pulse laser, adjust the laser pulse width of the pulse laser to 10ns, the wavelength to 1064nm, the energy to 500mJ, and the frequency to 15Hz; the laser focus is 1mm in diameter The light spot irradiates the w...

Embodiment 3

[0023] Embodiment 3: the preparation of black titanium dioxide powder, step is:

[0024] Use a tablet press to press the purchased anatase-type white titanium dioxide into a circular target with a diameter of 3cm and a thickness of 3mm, and the pressure is 140MPa; place the circular target in a vacuum tank, and vacuumize the vacuum tank. The internal pressure is 1×10 -6 Pa; adjust the angle between the incident laser beam of the pulse laser and the circular target to be 15°, the substrate of the pulse laser is a quartz substrate, and adjust the distance between the substrate base and the circular target to be 15mm to ensure that the product can Sputtering deposition on the substrate; turn on the pulse laser, adjust the pulse width of the pulse laser to 50ns, the wavelength to 532nm, the energy to 450mJ, and the frequency to be 10Hz; the laser is focused to a spot with a diameter of 1mm to irradiate the white titanium dioxide in the vacuum tank. For a circular target, the irra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| laser pulse width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com