Carbon quantum dot loaded cobalt-ruthenium alloy composite material, preparation method and application thereof

A technology of carbon quantum dots and composite materials, applied in the field of ammonia borane hydrolysis, can solve the problem of high cost of metal nanoparticle agglomeration catalyst, and achieve the effects of improving activity and cycle stability, improving stability and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

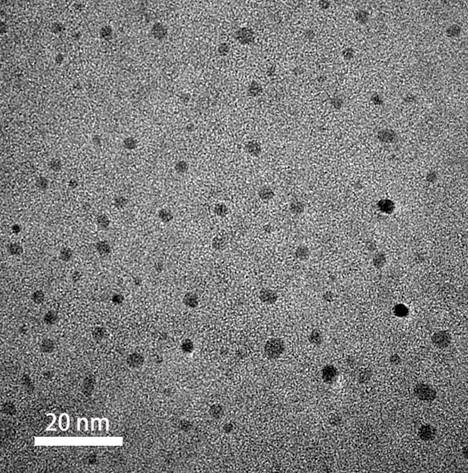

[0033] Preparation of a carbon quantum dot-supported cobalt-ruthenium alloy composite material:

[0034] (a) Weigh 2 g of shredded tobacco, put it into a 150 mL hydrothermal reaction kettle, add 100 mL of deionized water, heat it at 180 °C for 4 h, cool to room temperature, and filter to obtain 4 g / L yellow Brown carbon dot solution;

[0035] (b) Weigh Co(NO 3 ) 2 ·6H 2 O 291 mg was added to the above solution, stirred for 30 min, and then RuCl was added according to the molar ratio Co:Ru=1:1 3 ·3H 2 O, stirred for 1.5 h, then transferred the obtained black solution to a 150 mL hydrothermal reactor, heated it in water at 200 °C for 8 h, cooled to room temperature, centrifuged the product at 10000 rpm for 10 min, and obtained The precipitate was vacuum dried at 60 °C to obtain the precursor powder;

[0036] (c) Finally, the above precursor powder was calcined at 600 °C for 6 h in a nitrogen atmosphere to obtain a carbon quantum dot-supported cobalt-ruthenium alloy composi...

Embodiment 2

[0038] Preparation of a carbon quantum dot-supported cobalt-ruthenium alloy composite material:

[0039] (a), with embodiment 1;

[0040] (b) Weigh Co(NO 3 ) 2 ·6H 2 O 291 mg was added to the above solution, stirred for 30 min, and then RuCl was added according to the molar ratio Co:Ru=1:0.5 3 ·3H 2 O, stirred for 1.5 h, then transferred the obtained black solution to a 150 mL hydrothermal reactor, heated it in water at 200 °C for 8 h, cooled to room temperature, centrifuged the product at 10000 rpm for 10 min, and obtained The precipitate was vacuum dried at 60 °C to obtain the precursor powder;

[0041] (c), as in Example 1, the obtained carbon quantum dot-supported cobalt-ruthenium alloy composite material is marked as CoRu0.5 / CQDs composite material.

Embodiment 3

[0043] Preparation of a carbon quantum dot-supported cobalt-ruthenium alloy composite material:

[0044] (a), with embodiment 1;

[0045] (b) Weigh Co(NO 3 ) 2 ·6H 2 O 145.5 mg was added to the above solution, stirred for 30 min, and then RuCl was added according to the molar ratio Co:Ru=1:0.3 3 ·3H 2 O, stirred for 1.5 h, then transferred the obtained black solution to a 150 mL hydrothermal reactor, heated it in water at 200 °C for 8 h, cooled to room temperature, centrifuged the product at 10000 rpm for 10 min, and obtained The precipitate was vacuum dried at 60 °C to obtain the precursor powder;

[0046] (c), as in Example 1, the obtained carbon quantum dot-supported cobalt-ruthenium alloy composite material is marked as CoRu0.3 / CQDs composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com