Metal / ceramic microlaminate material and preparation thereof

A laminated material and ceramic microtechnology, applied in the field of material science, can solve the problems of low strength of metal sheets, brittle fracture of columnar grain boundaries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

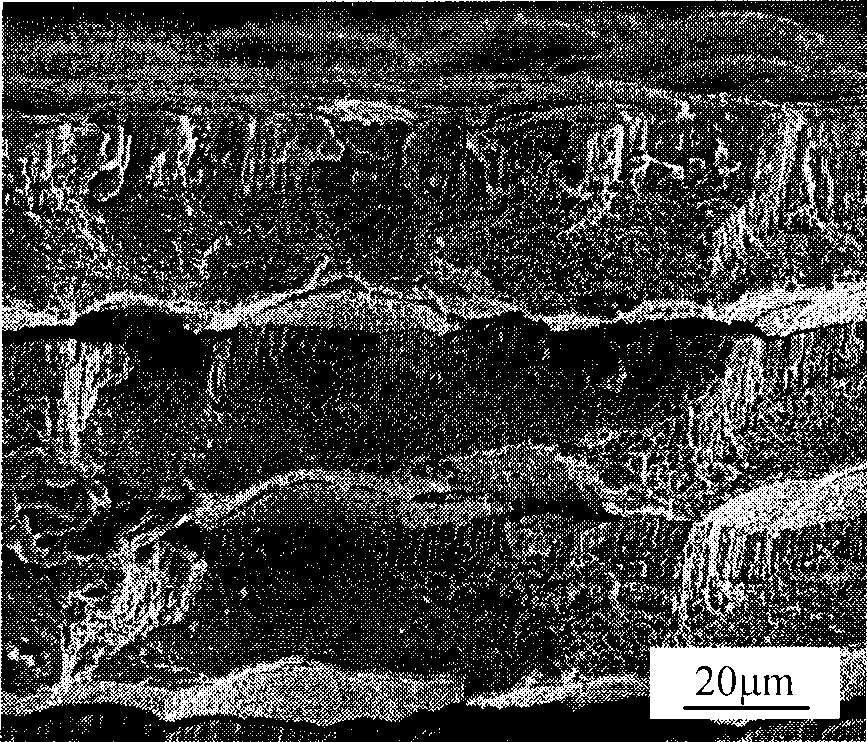

[0015] Embodiment 1, combining figure 1 , figure 2 , the preparation method of the metal / ceramic micro-laminated material of the present invention, one of the process:

[0016] (1) Vacuuming: Polish the surface of the φ1000mm substrate, and ultrasonically clean it in acetone for 10 minutes, dry it and connect it to the vertical rotating shaft at the top of the working chamber. Place the NiCoCrAl target and the YSZ target in two crucibles respectively. After placing them properly, evacuate to 10 -3 Pa.

[0017] (2) Heating the substrate: use a radiant heater to heat the substrate to above 500°C, and discharge the gas adsorbed on the substrate. Then the temperature of the substrate and the degree of vacuum are adjusted by means of intermittent heating. The vacuum is stable at 10 -3 ~10 -2 After Pa, stabilize the substrate temperature within the range of 650±20°C. At the same time, the rotation speed of the substrate is controlled by the motor to be 6 rpm.

[0018] (3) D...

Embodiment 2

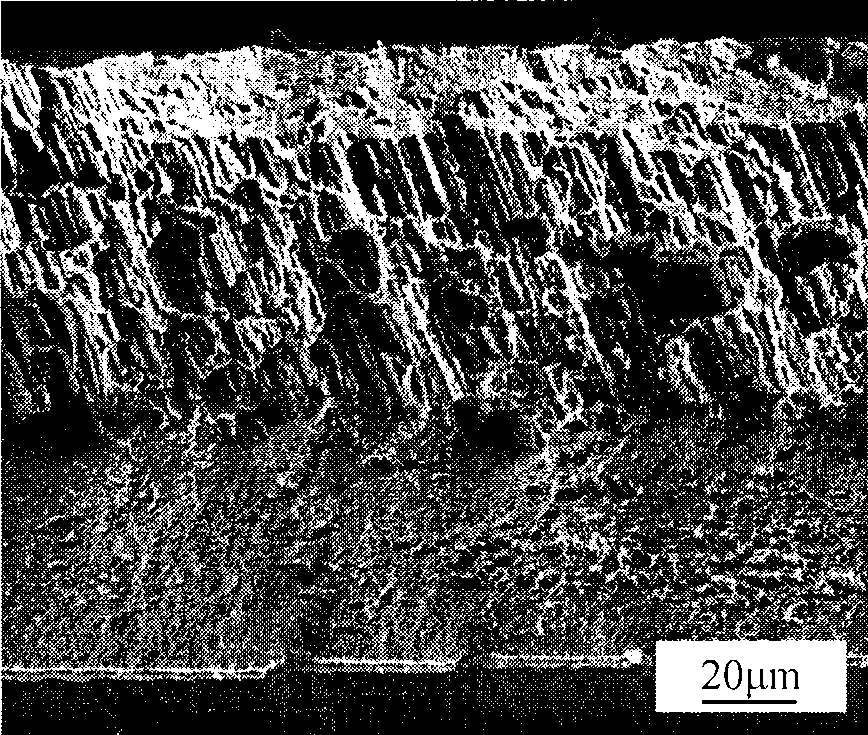

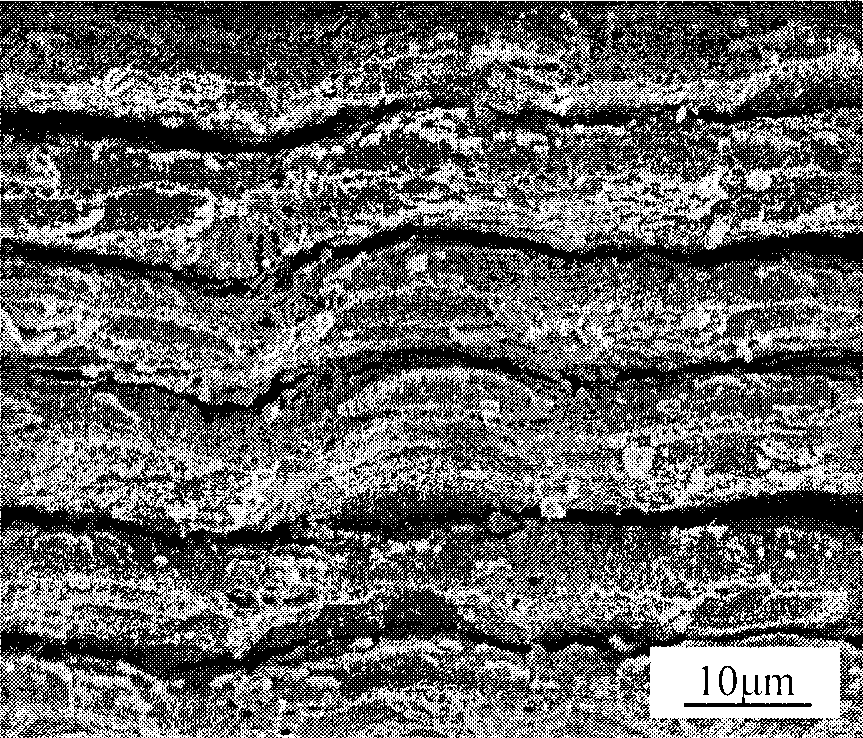

[0022] Example 2, combined with figure 1 , figure 2 , image 3 , the preparation method of the metal / ceramic micro-laminated material of the present invention, process two:

[0023] (1) Vacuuming: Polish the surface of the φ1000mm substrate, and ultrasonically clean it in acetone for 10 minutes, dry it and connect it to the vertical rotating shaft at the top of the working chamber. Place the NiCoCrAl target and the YSZ target in two crucibles respectively. After placing them properly, evacuate to 10 -3 Pa.

[0024] (2) Heating the substrate: use a radiant heater to heat the substrate to above 500°C, and discharge the gas adsorbed on the substrate. Then the temperature of the substrate and the degree of vacuum are adjusted by means of intermittent heating. The vacuum is stable at 10 -3 ~10 -2 After Pa, stabilize the substrate temperature within the range of 650±20°C. At the same time, the rotation speed of the substrate is controlled by the motor to be 6 rpm.

[0025]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength at room temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com