Preparation method for rapidly preparing highly-dispersed nickel-based catalyst for methane reforming with carbon dioxide

A reforming catalyst, carbon dioxide technology, applied in catalyst activation/preparation, molecular sieve catalyst, physical/chemical process catalyst, etc., can solve the problems of difficult to obtain dispersion catalyst, reduced catalyst activity, long cycle, etc., and achieves simple preparation process, The effect of strong interaction, good resistance to sintering and carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

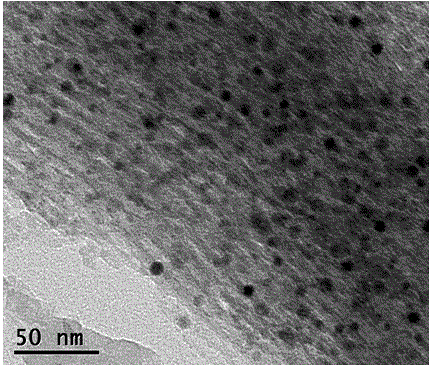

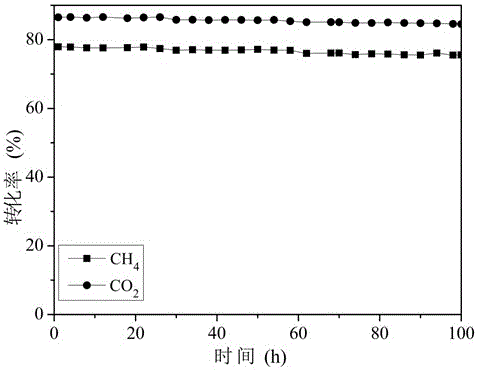

[0021] Weigh 4g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) and dissolve it in 120mL hydrochloric acid with a concentration of 2mol / L, stir in a constant temperature water bath (35°C) After 2 hours, after complete dissolution, 9 mL tetraethyl orthosilicate was added dropwise and stirred for 20 hours, then crystallized in an autoclave at 100°C for 24 hours, filtered, and dried to prepare the non-detemplated mesoporous material SBA-15. Weigh 0.2607g of nickel nitrate and 1g of undetemplated SBA-15 and grind them in a mortar with a nickel loading of 5wt%. Thoroughly grind to mix nickel nitrate and SBA-15 thoroughly, dry overnight at 100°C, and then heat up to 550°C for 4 hours in air atmosphere at a rate of 1°C / min. With pure H at a flow rate of 15 mL / min and a temperature of 700 °C 2 After flow reduction for 1 h, a highly dispersed nickel-based methane carbon dioxide reforming catalyst was obtained. The transmission electron microscope...

Embodiment 2

[0024] Weigh 6g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) and dissolve it in 210mL of deionized water, then add 11.8g of hydrochloric acid (35%), in a constant temperature water bath Stir at medium temperature (35°C) for 40min, after complete dissolution, add 6mL of n-butanol drop by drop, stir at 35°C for 1h, then add 12.9g of tetraethyl orthosilicate and stir for 24h, then place in the autoclave at 100°C Crystallize for 24 hours, filter, and dry to prepare the non-detemplated mesoporous material KIT-6. Weigh 0.2607g of nickel nitrate and 1g of undetemplated KIT-6 and grind them in a mortar with a nickel loading of 5wt%. Thoroughly grind to mix nickel nitrate and KIT-6 thoroughly, dry overnight at 100°C, and then heat up to 550°C for 4 hours in air atmosphere at a rate of 1°C / min. With pure H at a flow rate of 15 mL / min and a temperature of 700 °C 2 flow reduction for 1 h to obtain a highly dispersed nickel-based methane carbon d...

Embodiment 3

[0027] Weigh 3g of polypropylene glycol-ethylene oxide triblock copolymer (F127) and dissolve it in 185mL of hydrochloric acid with a concentration of 2mol / L, stir in a constant temperature water bath (at 25°C), and add 3.6g of trimethyl Benzene (TMB) and 15g KCl were stirred for 2 hours, 12.5g tetraethyl orthosilicate was added dropwise and stirred for 24 hours, and then crystallized in a high-pressure reactor at 100°C for 24 hours, filtered, and dried to prepare the non-detemplated mesoporous material FDU -12 carriers. Weigh 0.2048g of nickel nitrate and 1g of FDU-12 without template removal and grind them in a mortar with a nickel loading of 4wt%. Thoroughly grind to mix nickel nitrate and FDU-12 thoroughly, dry overnight at 100°C, and then heat up to 550°C for 4 hours in air atmosphere at a rate of 1°C / min. With pure H at a flow rate of 15 mL / min and a temperature of 700 °C 2 flow reduction for 1 h to obtain a highly dispersed nickel-based methane carbon dioxide reformin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com