Magnetic particle reinforced Al matrix composite and preparation method thereof

A composite material, enhanced aluminum-based technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., to achieve the effect of increasing tensile strength, improving strength, and high plastic toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

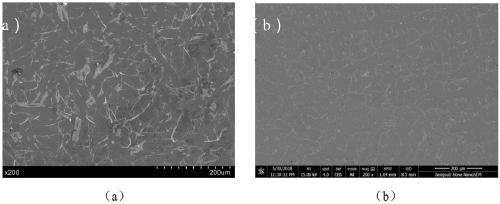

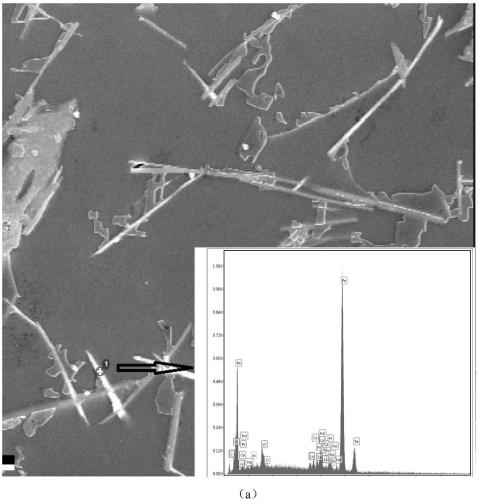

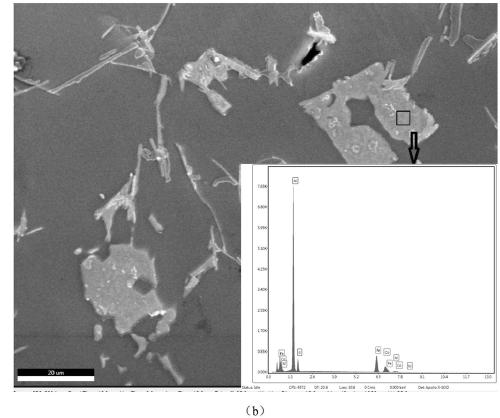

Image

Examples

preparation example Construction

[0023] A magnetic particle-reinforced aluminum-based composite material of the present invention and its preparation method are characterized in that the preparation process includes the following steps:

[0024] (a)Nd 2 Fe 14 Treatment of B powder: Nd 2 Fe 14 B powder is heated in a vacuum heating furnace at 640-660°C for 1-3 hours, and then Nd is added 2 Fe 14 B powder mass fraction 4-6% alcohol in a ball mill for 10-12 hours, then dry the ball-milled powder in a vacuum furnace for 1-2 hours at a drying temperature of 100-110°C to fully remove the attached water, and after cooling, use aluminum foil pack ready for use;

[0025] (b) Metal melt preparation: melting aluminum or aluminum alloy in a crucible furnace, refining and degassing when the temperature is raised to 730°C-750°C, and preparing for synthesis when the temperature is lowered to 610-620°C;

[0026] (c) Composite synthesis: Nd wrapped with aluminum foil 2 Fe 14 Add B powder into the molten aluminum, stir...

Embodiment 1

[0027] Example 1 1vol.% Nd 2 Fe 14 Preparation of B Particle Reinforced 2024 Aluminum Matrix Composites

[0028] The main components of 2024 are shown in Table 2. Target Nd 2 Fe 14 B particle volume fraction 1vol.% (mass fraction is 2.8%), initial aluminum amount is 1kg, Nd 2 Fe 14 B 28g.

[0029] Table 2 Chemical composition of 2024 aluminum alloy (wt%)

[0030]

[0031] The preparation process is: according to the amount of aluminum and the principle of ingredients, determine the Nd 2 Fe 14 After mass B, first heat the powder at 650°C under vacuum for 2 hours, then add Nd 2 Fe 14 B The powder mass fraction is 5% alcohol in a ball mill for 10 hours, and then the ball-milled powder is dried in a vacuum furnace for 2 hours at a drying temperature of 110°C to fully remove the attached water, and after cooling, wrap it with aluminum foil for use; Melting 2024 aluminum alloy in medium, refining and degassing when the temperature rises to 750°C, and when the temperatu...

Embodiment 2

[0032] Example 2 1vol.% Nd 2 Fe 14 Preparation of ZL101A Al-Matrix Composite Magnetic Material Reinforced by B Particles

[0033]The main components of ZL101A are listed in Table 1. Target Nd 2 Fe 14 B particle volume fraction 1vol.% (mass fraction 2.8%), initial aluminum amount is 1kg, Nd 2 Fe 14 B 28g.

[0034] Table 1 Chemical composition of ZL101A aluminum alloy (wt%)

[0035]

[0036] The preparation process is: according to the amount of aluminum and the principle of ingredients, determine the Nd 2 Fe 14 After B quality, first put Nd 2 Fe 14 B powder was heated under vacuum at 650°C for 3 hours, then Nd was added 2 Fe 14 The alcohol of B powder mass fraction 5% was ball-milled in ball mill for 10 hours, and the Nd that ball milled was good after that 2 Fe 14 Dry B powder in a vacuum oven for 1 hour at a temperature of 100°C to fully remove the attached water and alcohol. After cooling, wrap the powder with aluminum foil according to the amount of 20-30g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com