Method for preparing oleoyl tributyl citrate plasticizer

A technology of tributyl citrate and oleoyl citric acid, which is applied in the field of preparation of plastic plasticizers, can solve the problems of poor solvent resistance, poor thermal stability, poor migration resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

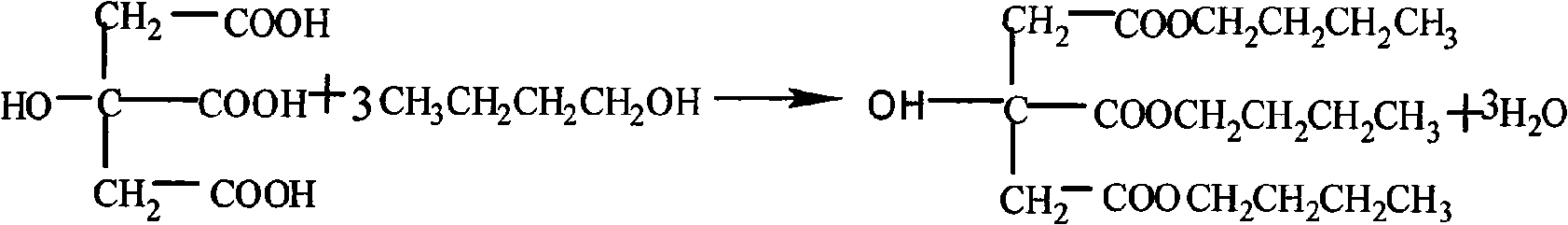

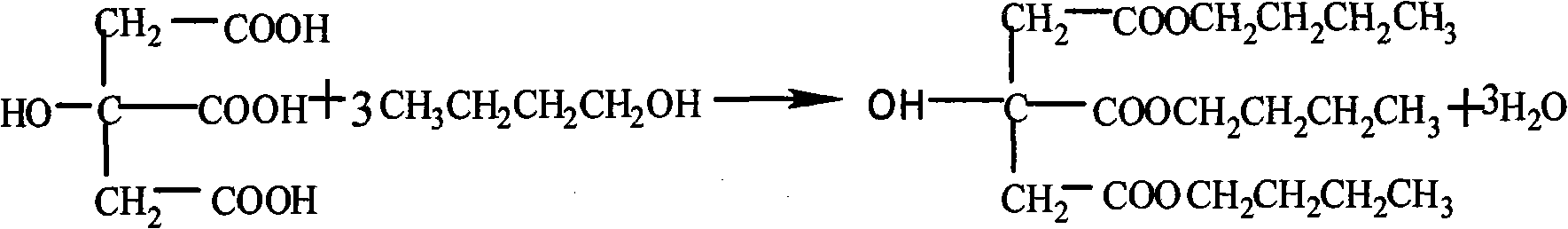

[0016] The present invention is the preparation method of oleoyl tributyl citrate plasticizer, and its synthetic route is as follows:

[0017] Step 1: Synthesis of tributyl citrate

[0018]

[0019] Step 2: Synthesis of oleoyl chloride

[0020] 3CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COOH+PCl 3 →3CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COCl+H 3 PO 3

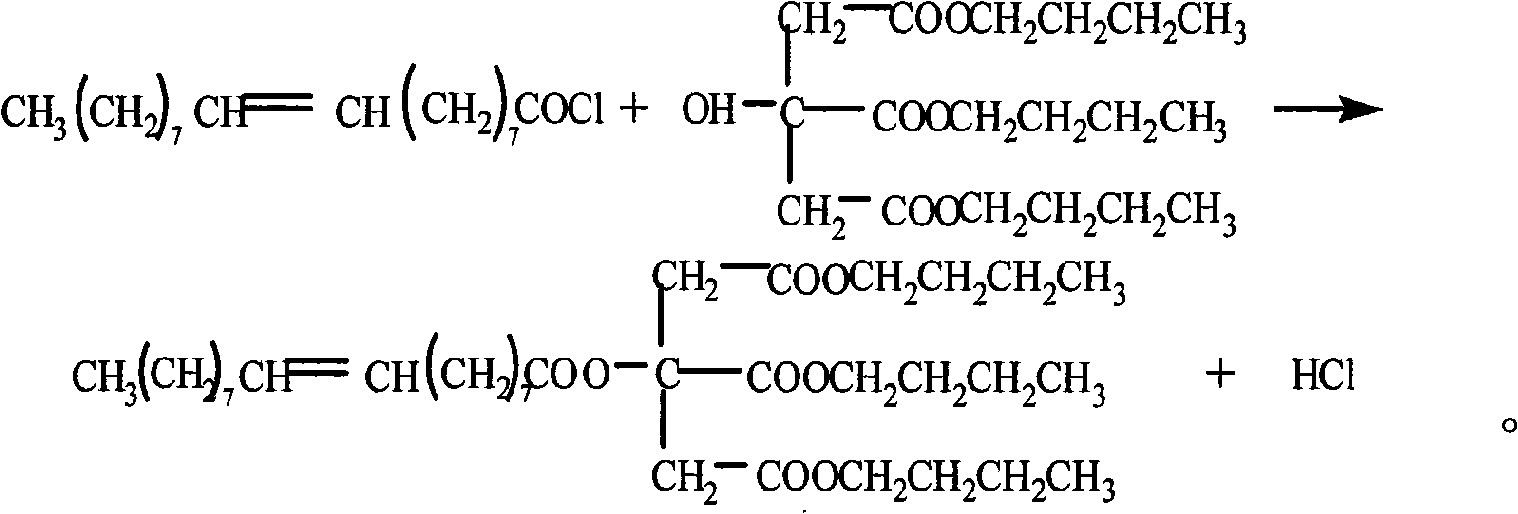

[0021] Step 3: Synthesis of oleoyl tributyl citrate

[0022]

[0023] Its specific synthetic steps are as follows:

[0024] Step 1: Synthesis of tributyl citrate. Add citric acid, n-butanol, water-carrying agent, and catalyst into a reactor equipped with electric stirring, electric heating cap heating, oil-water separation, reflux condenser, and temperature measurement system, start stirring and raise the temperature, and control the temperature at 96°C to Until anhydrous is generated, tributyl citrate is obtained;

[0025] Step 2: Synthesis of oleoyl chloride. In the reactor equipped with electric stirring, water bath heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com