Titanium dioxide sol and coating type denitration catalyst

A technology of titanium dioxide and sol, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, physical/chemical process catalysts, etc., and can solve the problems of low mass fraction and low coating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

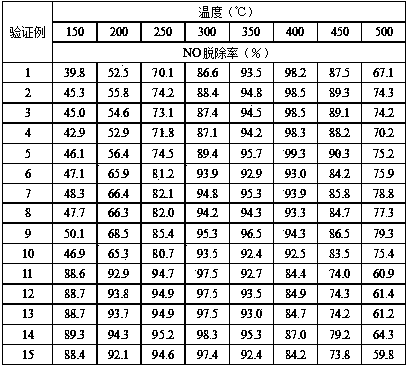

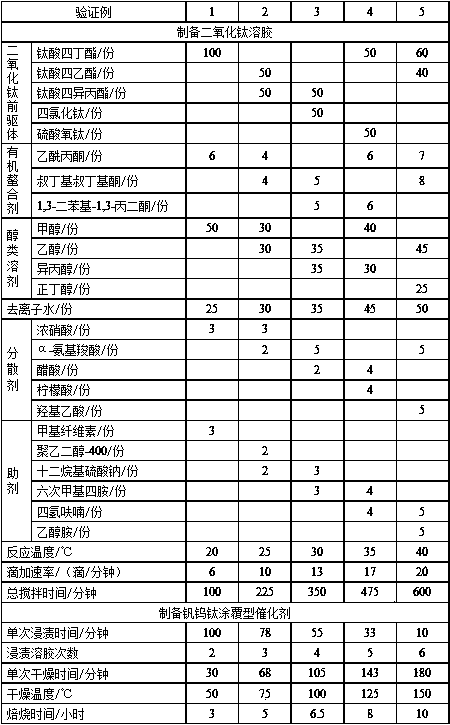

Examples

Embodiment Construction

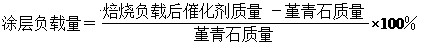

[0021] 1. A titania sol, the raw materials for preparing it include a titania precursor and a dispersant. In the present invention, the titanium dioxide precursor is tetrabutyl titanate [Ti(OC 4 h 9 ) 4 ], tetraethyl titanate [Ti(OC 2 h 5 ) 4 ], tetraisopropyl titanate [Ti(OC 3 h 7 ) 4 ], titanium tetrachloride (TiCl 4 ) and titanyl sulfate (TiOSO 4 ), the dispersant is concentrated nitric acid (HNO 3 ), α-aminocarboxylic acid (NH 2 CH 2 COOH), acetic acid (CH 3 COOH), citric acid (C 6 h 8 o 7 ) and glycolic acid (C 2 h 4 o 3 ) of one or both; in the raw materials there are also organic chelating agents, alcohol solvents, deionized water and auxiliary agents, wherein the organic chelating agents are acetylacetone (CH 3 COCH 2 COCH 3 ), tert-butyl tert-butyl ketone [(CH 3 ) 3 CCOC (CH 3 ) 3 ] and 1,3-diphenyl-1,3-propanedione or both, the alcoholic solvent is methanol (CH 4 O), ethanol (C 2 h 6 O), isopropanol [(CH 3 ) 2 CHOH] and n-butanol [CH 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com