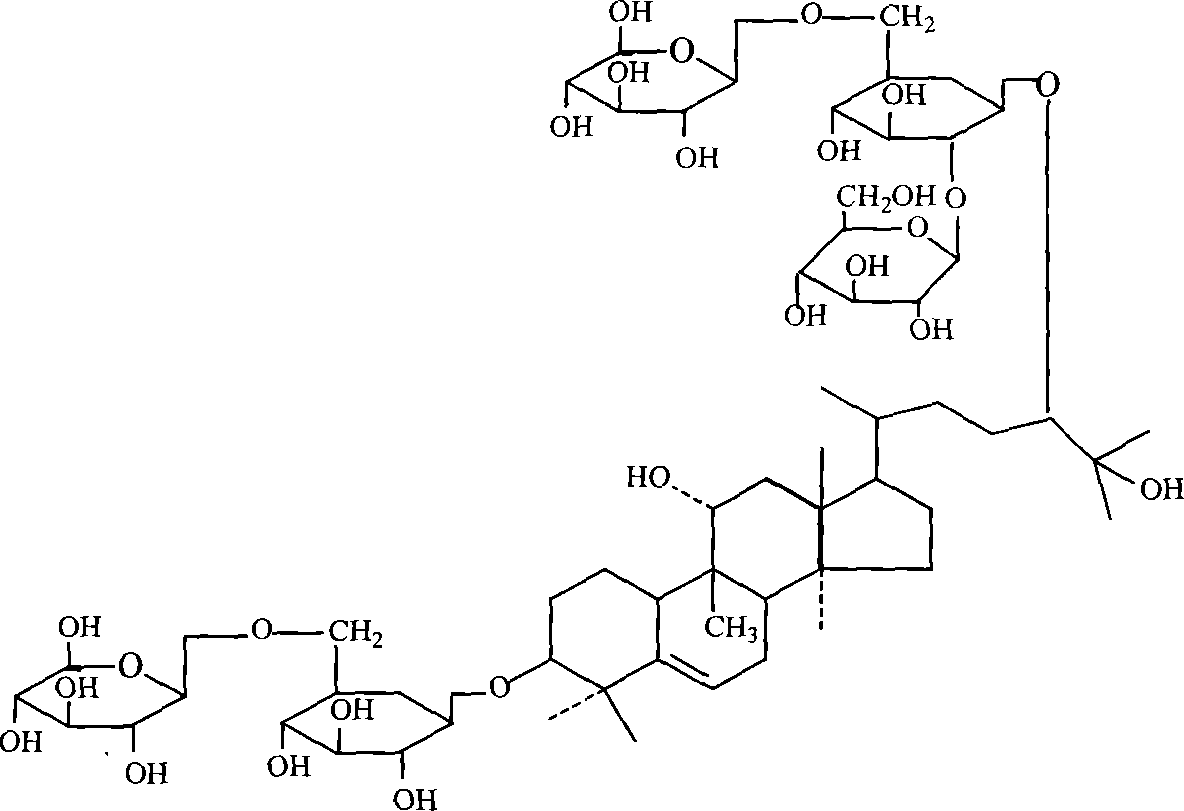

Method for preparing high-purity Momordia grosvenori aglycone from Momordia grosvenori

A mogroside and Luo Han Guo technology, applied in food preparation, steroids, organic chemistry and other directions, can solve problems such as complicated operation and toxicity, and achieve the effects of simplified process, low production cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment 1 is implemented under the following conditions of implementation and technical requirements:

[0018] 1. Add 1Kg of Luo Han Guo dried fruit, add 5L of 71% industrial ethanol to reflux for extraction for 2 hours, filter, recover ethanol from the filtrate (can be used again for medicinal material extraction), and obtain 94g of alcoholic extract.

[0019] 2. Take the alcoholic extract, add 470mL of water to suspend, then extract with 235mL of water-saturated ethyl acetate, separate the ethyl acetate layer, and recover ethyl acetate under reduced pressure (which can be used again for extraction) to obtain ethyl acetate Ester extract 13g.

[0020] 3. The aqueous solution extracted with ethyl acetate was further extracted with n-butanol saturated with water, and the dosage was 235 mL. The n-butanol was separated, and the n-butanol was recovered under reduced pressure (which could be used for extraction again) to obtain 15 g of n-butanol extract.

[0021] 4....

Embodiment 2

[0025] This embodiment 2 is implemented under the following conditions of implementation and technical requirements:

[0026] 1. Add 1Kg of Luo Han Guo dried fruit, add 10L of 95% industrial ethanol to reflux and extract for 6 hours, filter, and recover ethanol from the filtrate (which can be used again for medicinal material extraction) to obtain an extract. Repeat the above operation 2 times to obtain 168g of alcoholic extract.

[0027] 2. Take the alcoholic extract, add 1680mL of water to suspend it, then extract with 1680mL of water-saturated ethyl acetate, separate the ethyl acetate layer, and reclaim the ethyl acetate under reduced pressure (which can be used again for extraction) to obtain the extract. Repeat the above operation 2 times, combine the extracts to obtain 21g of ethyl acetate extract.

[0028] 3. The aqueous solution extracted with ethyl acetate was further extracted with n-butanol saturated with water, and the dosage was 1680 mL. The n-butanol is separat...

Embodiment 3

[0033] This embodiment 3 is implemented under the following conditions of implementation and technical requirements:

[0034] 1. Add 7.5L of 80% industrial ethanol to 1Kg of dried Luo Han Guo, reflux for extraction for 4 hours, filter, and recover ethanol from the filtrate (which can be used again for medicinal material extraction) to obtain an extract. Repeat the above operation once to obtain 133g of alcoholic extract.

[0035] 2. Take the alcoholic extract, add 998mL of water to suspend it, then extract it with 749mL of water-saturated ethyl acetate, separate the ethyl acetate layer, and reclaim the ethyl acetate under reduced pressure (which can be used again for extraction) to obtain the extract. Repeat the above operation once to obtain 18 g of ethyl acetate extract.

[0036] 3. The aqueous solution extracted with ethyl acetate was further extracted with n-butanol saturated with water, and the dosage was 749 mL. Isolate n-butanol, recover n-butanol (can be used for ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com