Method for preparing tributyl citrate using mesoporous molecular sieve as catalyst

A technology of tributyl citrate and mesoporous molecular sieves, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of severe equipment corrosion, complicated post-processing, and difficult refining, and achieve mild reaction conditions. , The amount of catalyst is small, and there is no effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

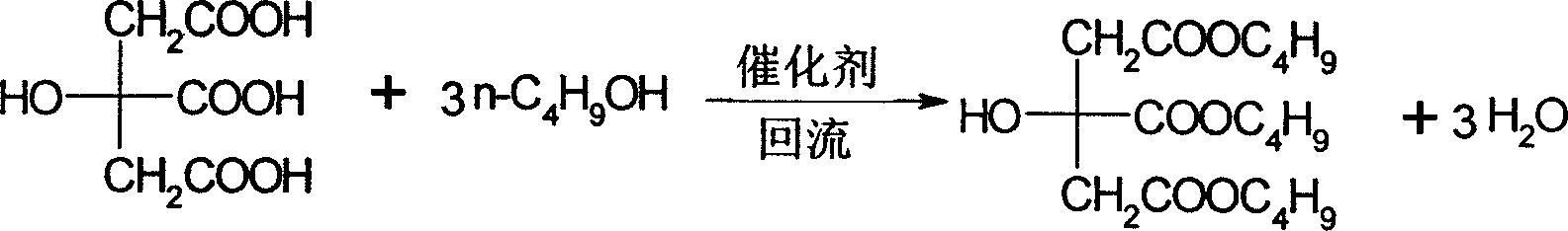

Image

Examples

Embodiment 1

[0019] Preparation of the first step catalyst HAl-MCM-41 mesoporous molecular sieve

[0020] With the Al-MCM-41 mesoporous molecular sieve that prior art makes, through the NH of 4mol / L 4 NO 3 Exchange the aqueous solution and roast at 550°C (three times) to obtain HAl-MCM-41 mesoporous molecular sieve;

[0021] Step 2 Esterification Reaction

[0022] Add 0.1mol citric acid and 0.45mol n-butanol into a 100mL three-necked bottle equipped with electromagnetic stirring, thermometer, reflux condenser, and water separator for heating and stirring. After the citric acid is completely dissolved, take a sample to determine the acid value, and then add 0.3 g of HAl-MCM-41 molecular sieve, heat and reflux and stir, separate the water produced by the reaction from the water separator, react until anhydrous (about 4h), take a sample to measure the acid value, the acid value is determined according to GB / T1668-1995 Determination;

[0023] Step 3 Separation of catalyst and purification ...

Embodiment 2-4

[0026] Except for the following differences, the rest are the same as in Example 1, the amount of HAl-MCM-41 molecular sieve is 0.3g, the amount of citric acid is 0.1mol, the amount of n-butanol is according to the ratio in Table 1, and the reaction is 4h.

[0027] Example

Embodiment 5-7

[0029] Except the following difference, all the other are identical with embodiment 1, and the consumption of HAl-MCM-41 molecular sieve is according to table 2 respectively.

[0030] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com