High-stability DSA anode for preparing chlorine by electrolysis and preparation method thereof

A high-stability, anode technology, applied in the field of applied electrochemistry, can solve the problems of the cost of Pt and the insignificant effect of chlorine-evolution coating anode, to prevent the formation of high-resistance TiO2, improve electrochemical stability, and enhance bonding force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

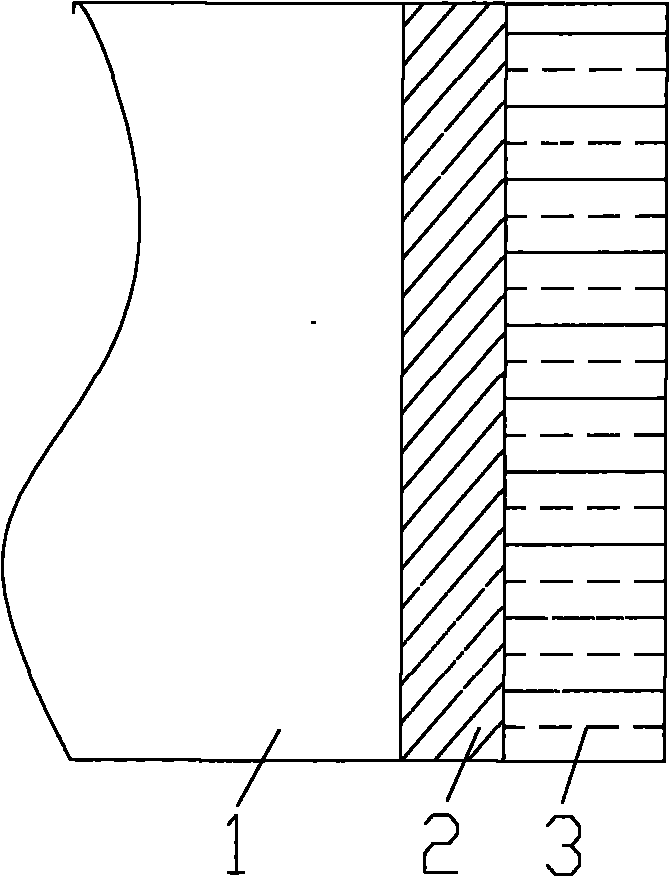

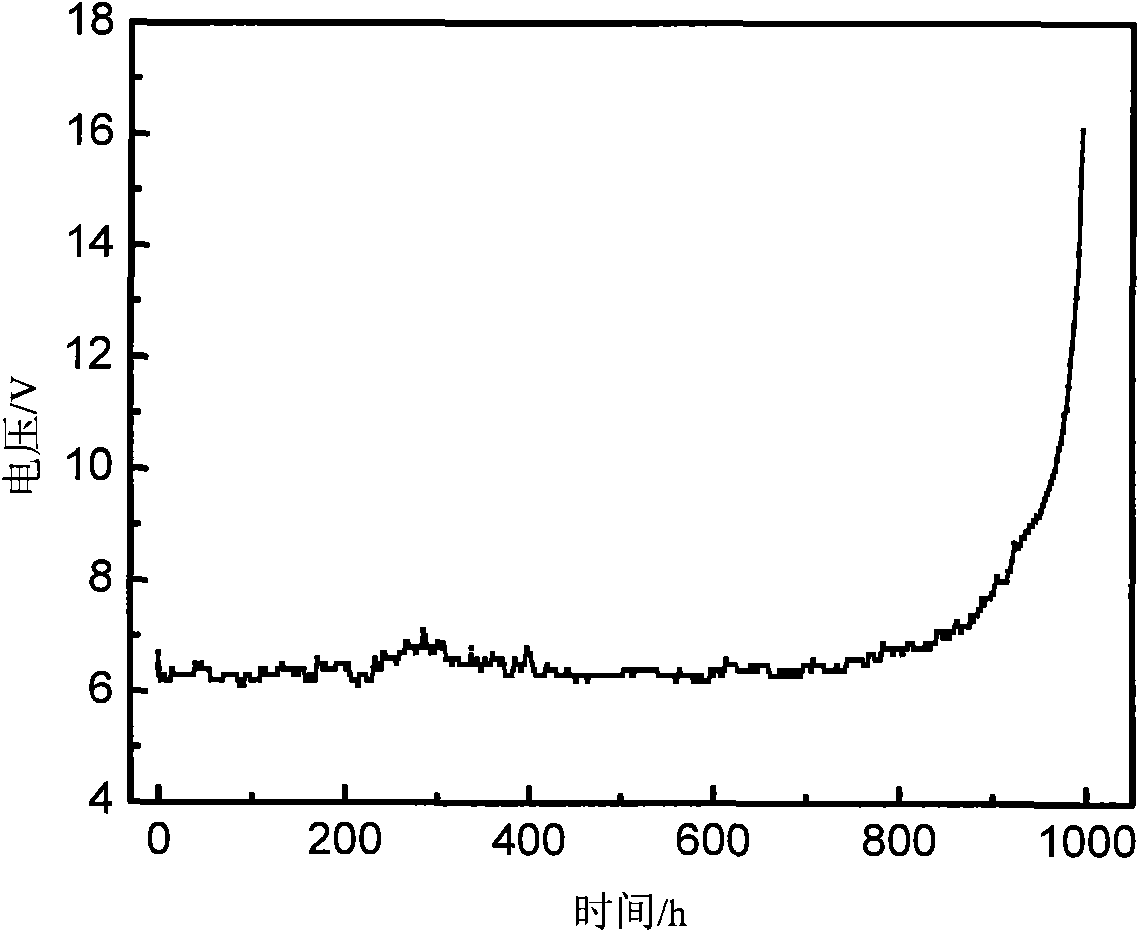

[0027] Cut the titanium substrate 1 into sheet samples with a size of 1 cm×5 cm, wash with alkali to degrease, pickle and etch, then wash and dry. Take appropriate amount of H according to Ir:Mn=7:3 2 IrCl 6 , 50% Mn(NO 3 ) 2 The solution was dissolved in n-butanol as an intermediate protective layer 2 coating solution. According to Ru:Ti:Sn=24:56:20, appropriate amount of ruthenium chloride, titanium trichloride hydrochloric acid solution, and tin chloride are dissolved in isopropanol solution as the surface active layer 3 coating solution. Firstly, the intermediate layer coating solution is evenly coated on the surface of the titanium substrate 1, dried in a 90°C drying oven for 10 minutes, then sintered in a 450°C muffle furnace for 10 minutes, taken out and cooled, and the above steps are repeated 5 times. Then apply the surface layer coating solution evenly on the middle protective layer 2, dry in a 90°C drying oven for 10 minutes, then sinter in a 450°C muffle furnac...

Embodiment 2

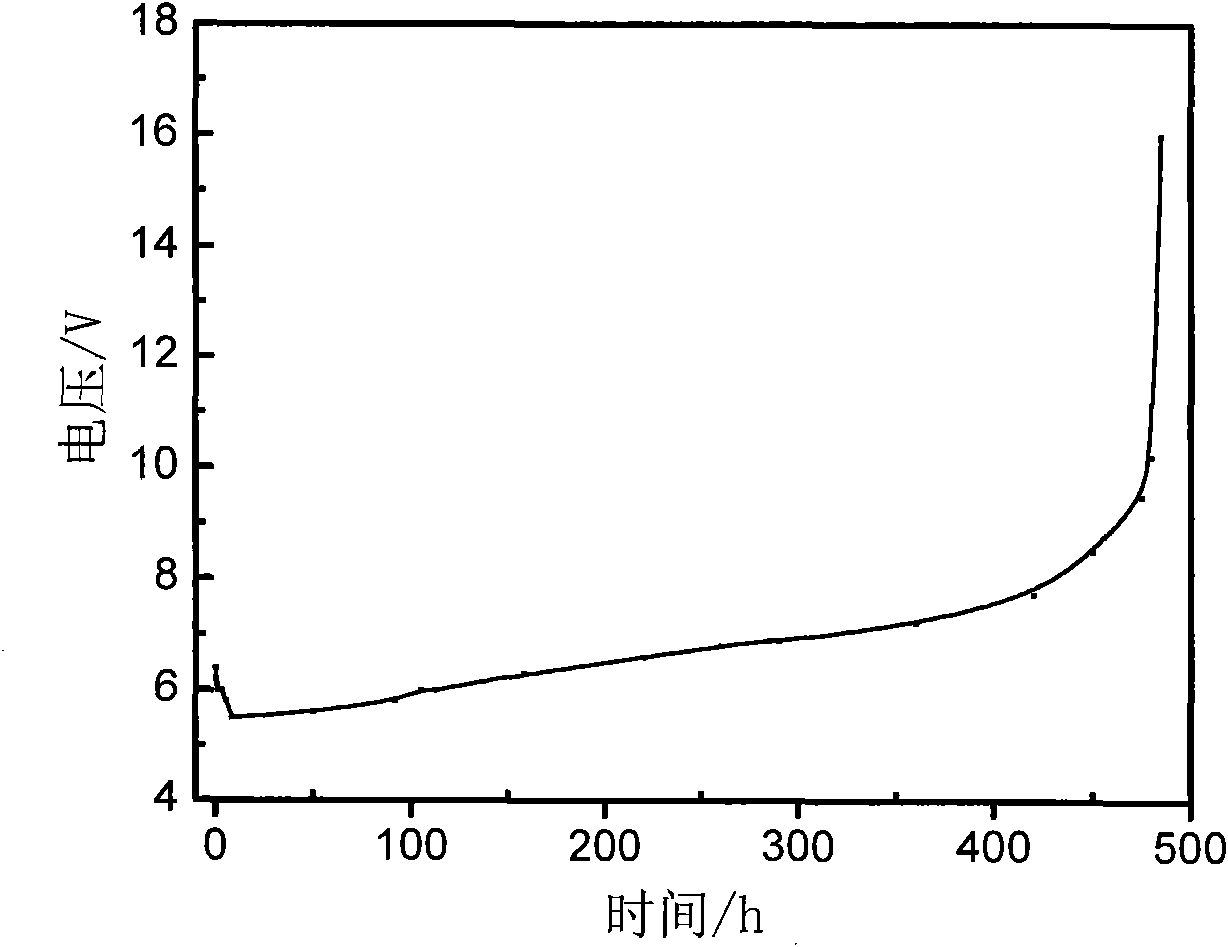

[0030] Titanium substrate 1 is treated as in Example 1, and an appropriate amount of H is taken according to Ir:Co=7:3 2 IrCl 6 , Co(NO 3 ) 2 Dissolved in n-butanol as the intermediate protective layer 2 coating solution. Prepare the surface active layer 3 coating solution according to Example 1. Anode No. 2 was prepared according to Example 1. And the anode was subjected to an enhanced life test according to the test method described in Example 1. From image 3 It can be seen that the introduction of Ir 0.7 co 0.3 The anodic strengthening life of the O intermediate protective layer 2 has reached 480h.

Embodiment 3

[0032] The titanium substrate is treated as in Example 1, and an appropriate amount of H is taken according to Ir:Ta:Co=14:6:3 2 IrCl 6 , TaCl 5 , Co(NO 3 ) 2 Dissolved in n-butanol as the intermediate protective layer 2 coating solution. Prepare the surface active layer 3 coating solution according to Example 1. Anode No. 1 was prepared according to Example 1. And the enhanced life test of the anode: the electrolyte is 0.5mol / L H 2 SO 4 Solution, temperature 40°C, high current density 4A / cm 2 , record the time and the corresponding tank pressure change. When the cell pressure rises rapidly by 10V, the anode is considered to be in failure. From Figure 4 It can be seen that the anodic strengthening life of the introduction of the intermediate protective layer 2 has reached 240h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com