Aqueous UV paint and preparation method thereof

A water-based, formulated technology, applied in the field of paint, can solve the problems of paint film resistance to alcohol, poor chemical resistance, poor adhesion, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

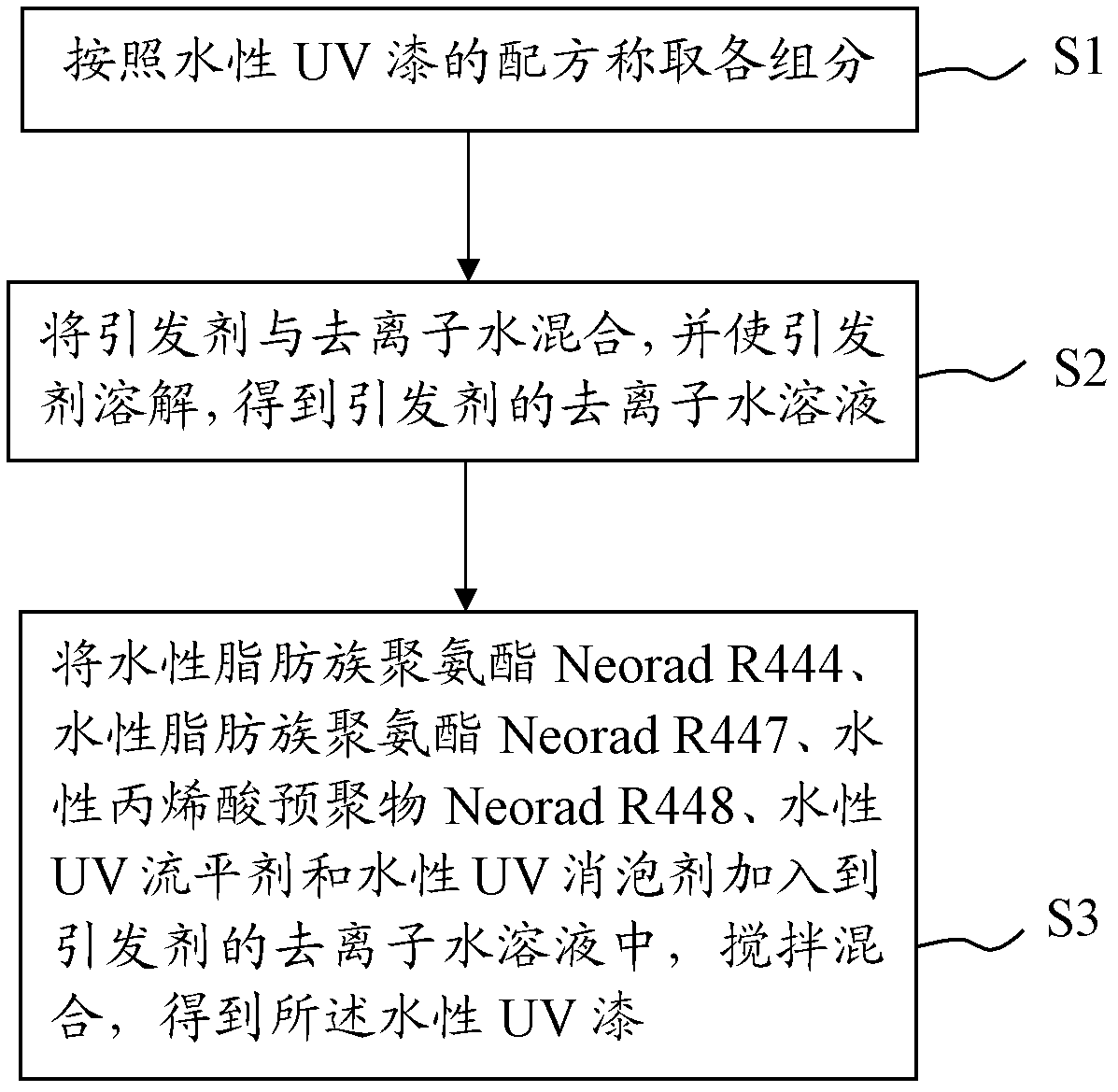

Method used

Image

Examples

Embodiment 1

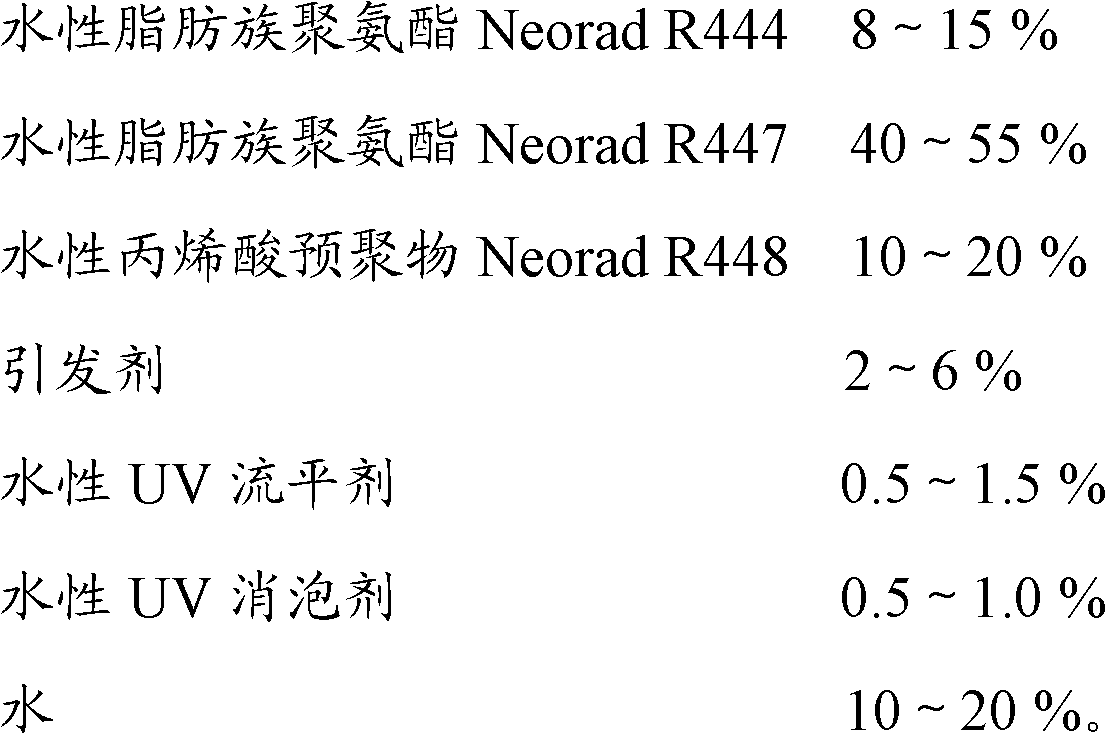

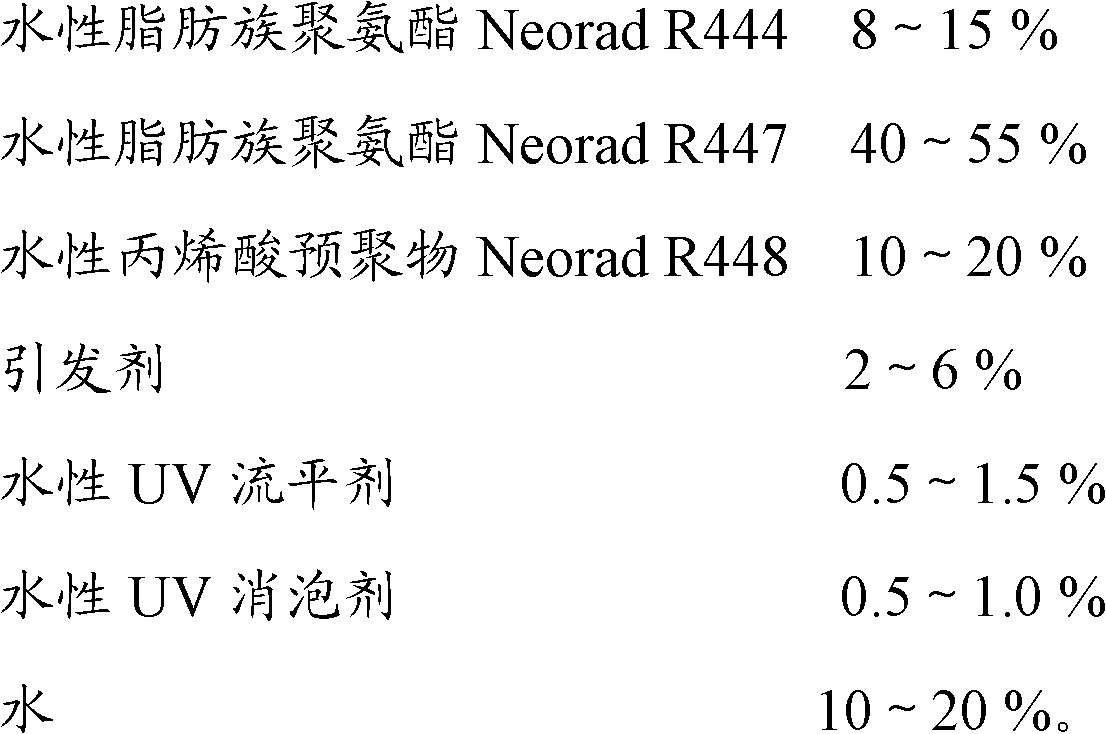

[0040] The formulation and preparation method of water-based UV paint:

[0041]

[0042]

[0043] Its preparation method of this water-based UV paint is as follows:

[0044] S11: Weigh each component according to the formula of the above-mentioned water-based UV paint;

[0045] S12: Mix the initiator with deionized water, adjust the pH of the solution to 8-9 with an ammonia pH regulator, stir at a slow speed of 600 r / s for 13 minutes to completely dissolve the initiator, and dissolve the initiator;

[0046] S13: Add water-based aliphatic polyurethane Neorad R444, water-based aliphatic polyurethane Neorad R447, water-based acrylic prepolymer Neorad R448, initiator, water-based UV leveling agent, mixed propanol and water-based UV defoamer initiator to the initiator containing initiator In the deionized aqueous solution, stir at a medium speed of 800 r / s for 30 minutes to mix the components uniformly to obtain the water-based UV paint.

[0047] The water-based UV paint pr...

Embodiment 2

[0056] The formulation and preparation method of water-based UV paint:

[0057]

[0058]

[0059] Its preparation method of this water-based UV paint is as follows:

[0060] S21: Weigh each component according to the formula of the above-mentioned water-based UV paint;

[0061] S22: Mix the initiator with deionized water, and adjust the pH of the solution to 8 to 9 using a sodium bicarbonate (5%) solution pH regulator, and stir at a slow speed of 400r / s for 15 minutes to completely dissolve the initiator. and dissolve the initiator;

[0062] S23: Add water-based aliphatic polyurethane Neorad R444, water-based aliphatic polyurethane Neorad R447, water-based acrylic prepolymer Neorad R448, initiator, water-based UV leveling agent and water-based UV defoamer initiator to the deionized aqueous solution containing the initiator In the process, stir at a medium speed of 600r / s for 50 minutes to mix the components uniformly to obtain the water-based UV paint.

[0063] Throug...

Embodiment 3

[0065] The formulation and preparation method of water-based UV paint:

[0066]

[0067] Its preparation method of this water-based UV paint is as follows:

[0068] S31: Weigh each component according to the formula of the above-mentioned water-based UV paint;

[0069] S32: Mix the initiator with deionized water, and use sodium bicarbonate (5%) solution (name) pH adjuster to adjust the pH of the solution to 8-9, and stir at a medium speed of 500r / s for 10 minutes to make the initiator Completely dissolve and dissolve the initiator;

[0070] S33: Add water-based aliphatic polyurethane Neorad R444, water-based aliphatic polyurethane Neorad R447, water-based acrylic prepolymer Neorad R448, initiator, water-based UV leveling agent and water-based UV defoamer initiator to the deionized aqueous solution containing the initiator , stirring at a medium speed of 600r / s for 40 minutes to mix the components uniformly to obtain the water-based UV paint.

[0071] Through the relevant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water resistance | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com