Method for manufacturing blue and white porcelain staircase

A production method, the technology of blue and white porcelain, is applied in the direction of manufacturing tools, wood processing utensils, and devices for coating liquid on the surface, which can solve problems such as single color and pattern, traditional and old-fashioned production technology, and difficulty in satisfying high-end consumers. Achieve the effect of high hardness of the paint film, obvious three-dimensional color and rich layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

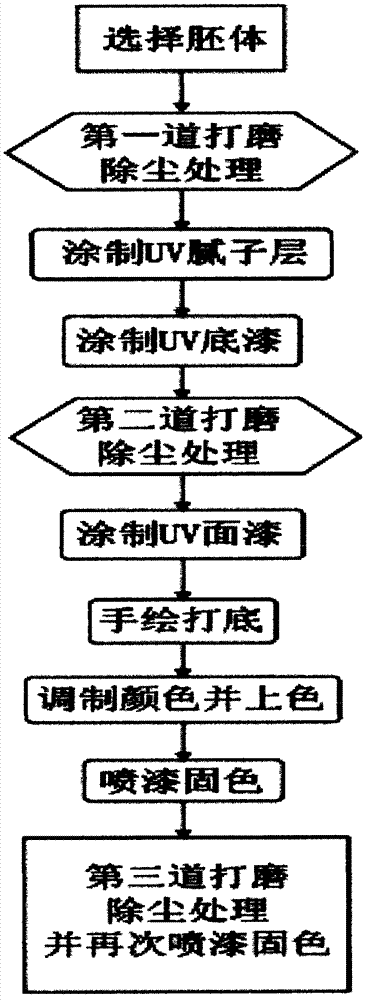

[0035] refer to figure 1 Shown, the technical problem solved by the present invention adopts following technical scheme to realize:

[0036] A method for making a blue and white porcelain wooden staircase, the method comprising the steps of:

[0037] Step a, select the blue and white porcelain process to make the embryo body, and carry out the first grinding and dust removal treatment to the embryo body;

[0038] Making stair treads, vertical boards, columns, handrails, girders and general columns, wherein at least the vertical board and the vertical column are selected as the blue and white porcelain process to make the embryo body, and the embryo body is sanded mechanically or manually, and Dust removal.

[0039] 1. Sanding:

[0040] Use 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com