Tetracarboxylic dianhydride containing triazole, polymer, liquid crystal aligning agent, liquid crystal aligning membrane, and display element

A technology of tetracarboxylic dianhydride and liquid crystal aligning agent, used in liquid crystal materials, organic chemistry, instruments, etc., can solve the problems of reduction, panel display quality reduction, film peeling, etc., and achieve high film hardness, good electrical properties, good Show performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0776] [Example 1] Synthesis of compound (1-1)

[0777] [chem 163]

[0778]

[0779]

[0780] 4-(4-Bromobutyl) diethyl phthalate (12.1 g, 34.0 mol) was placed in a three-necked flask equipped with a thermometer and a nitrogen inlet tube, and 70 mL of DMF was added thereto. Sodium azide (2.4 g, 37.4 mmol) was added thereto. Thereafter, the solution was heated to 60° C., and stirred at the same temperature for 3 hours under a nitrogen atmosphere. The reaction solution was added to 400 mL of water, and extracted twice with 300 mL of heptane. After drying the organic layer with magnesium sulfate, the solvent was distilled off under reduced pressure to obtain a 4-(4-azidobutyl)-phthalic acid diethyl ester compound (yield: 10.0 g, yield: 92%).

[0781]

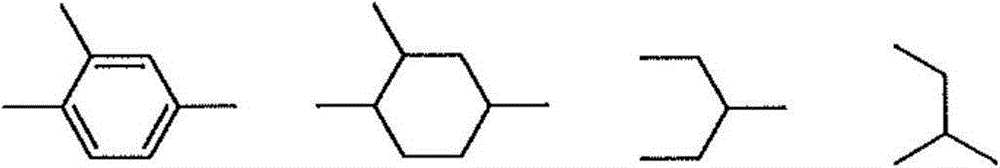

[0782] 4-(4-azidobutyl) diethyl phthalate (10.0 g, 31.3 mmol), 4-ethynyl - Dimethyl phthalate (7.5 g, 34.4 mmol), add 50 mL of dichloromethane and 50 mL of water. After stirring at room temperature to dissolve the compou...

Embodiment 2

[0793] [Example 2] Synthesis of compound (1-5)

[0794] [chem 166]

[0795]

[0796]

[0797]1,6-Dibromohexane (5.0 g, 20.5 mmol) was put into a 100 mL three-necked flask equipped with a thermometer and a nitrogen inlet tube, and 25 mL of DMF was added. Sodium azide (2.9 g, 45.6 mmol) was added thereto. Thereafter, the solution was heated to 60° C., and stirred at the same temperature for 3 hours under a nitrogen atmosphere. The reaction solution was added to 200 mL of water, and extracted twice with 100 mL of heptane. After drying the organic layer with magnesium sulfate, the solvent was distilled off under reduced pressure to obtain 1,6-diazidohexane (3.2 g of yield, 93% yield).

[0798]

[0799] Put 1,6-diazidohexane (2.2 g, 13.1 mmol) and 4-ethynyl-phthalic acid dimethyl ester (5.7 g, 26.2 mmol) obtained in the first stage, and add 5 mL of diazide Chloromethane with 5 mL of water. After stirring at room temperature to dissolve the compound, copper sulfate penta...

Embodiment 3

[0810] [Example 3] Synthesis of compound (1-6)

[0811] [chem 169]

[0812]

[0813]

[0814] Put 1,6-diazidohexane (2.2g, 13.1mmol), 4-ethynyl-1,2-cyclohexanedicarboxylic acid dimethyl ester (6.2g, 27.5mmol), add 20ml of dichloro Methane and 20ml of water. After stirring at room temperature to dissolve the compound, copper sulfate pentahydrate (0.16 g, 0.65 mmol) and L-sodium ascorbate (0.26 g, 13 mmol) were added, followed by stirring at room temperature for 1 hour. The reaction solution was added to 50 ml of water, and extracted twice with 50 ml of toluene. After drying the organic layer over magnesium sulfate, the solvent was distilled off under reduced pressure to obtain a crude product. The crude product was purified by column chromatography to obtain the following compound (yield: 7.8 g, yield: 97%).

[0815] [chem 170]

[0816]

[0817]

[0818] The compound (7.0 g, 11.3 mmol) obtained in the first stage was added to a three-necked flask equipped with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com