Organic-silicon-modified aqueous polyester resin and preparation method of same

A water-based polyester resin and silicone technology, applied in the field of polyester resin, can solve the problems of low film hardness, poor heat resistance, large solvent consumption, etc., and achieve the effect of high film hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

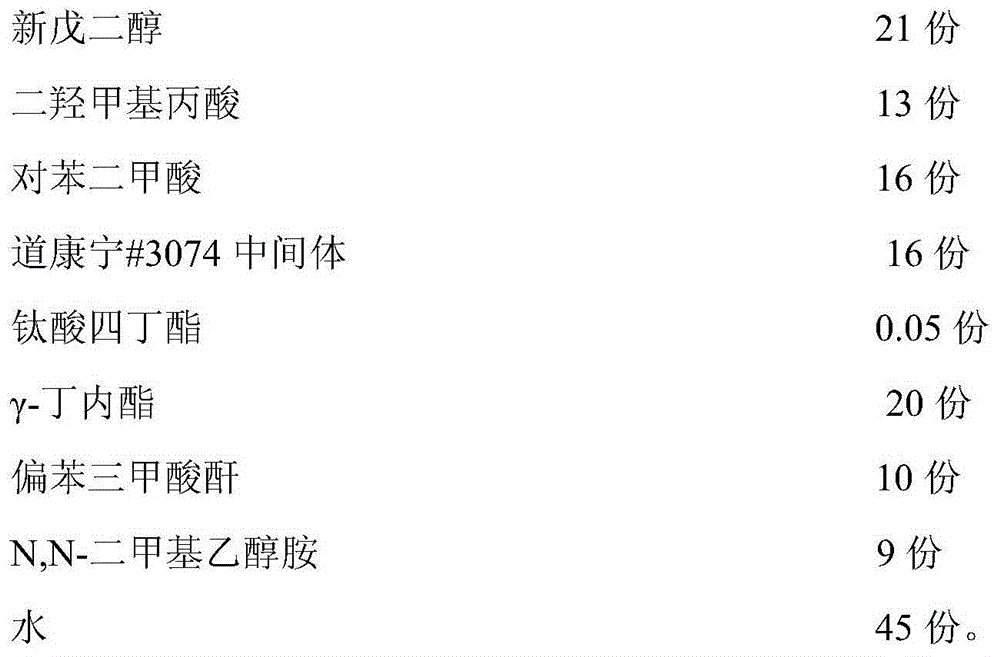

[0022] A kind of organosilicon modified waterborne polyester resin, proportioning by weight is as follows:

[0023]

[0024] Preparation process: Take 21 parts by weight of neopentyl glycol, 13 parts by weight of dimethylolpropionic acid, and 16 parts by weight of terephthalic acid, and heat up to 120°C to dissolve; protect with nitrogen, start stirring, and control the temperature at 185°C -240°C, until the theoretical weight part of condensate is collected. Cool down the temperature of the material to about 130°C, add 16 parts by weight of Dow Corning #3074 intermediate, 0.05 parts by weight of tetrabutyl titanate, control the temperature at 120°C-140°C for 1 hour; add 10 parts by weight of trimellitic anhydride, control The temperature is 120°C, react for 40min; stop heating, cool naturally to 90°C, add 20 parts by weight of γ-butyrolactone, 9 parts by weight of N,N-dimethylethanolamine, 45 parts by weight of water and stir for 15 minutes, mix After uniformity, the mate...

Embodiment 2

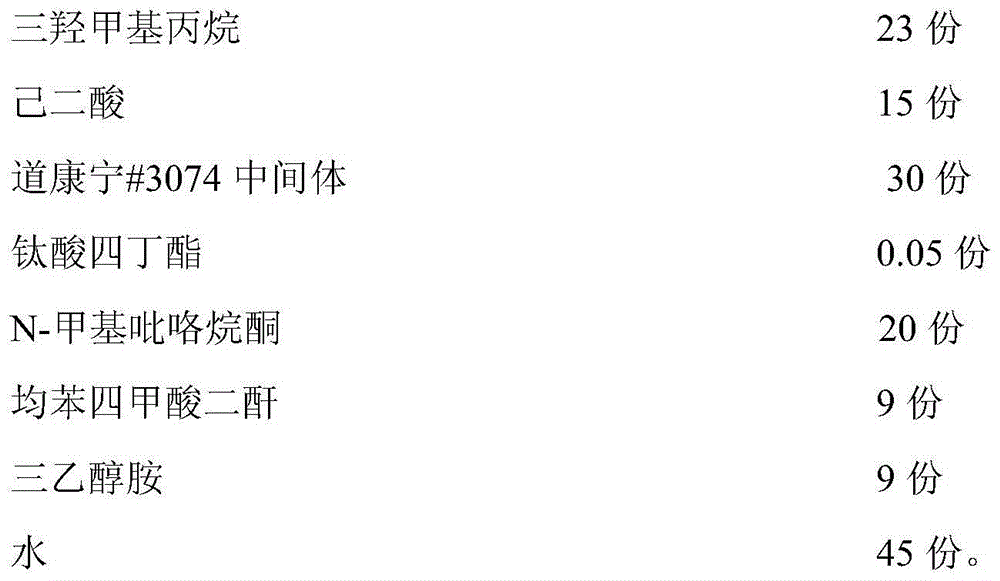

[0026] A kind of organosilicon modified waterborne polyester resin, proportioning by weight is as follows:

[0027]

[0028] Preparation process: Take 23 parts by weight of trimethylolpropane and 15 parts by weight of adipic acid, heat up to 120°C to dissolve; pass nitrogen protection, start stirring, control the temperature at 185°C-240°C, until the theoretical weight of condensation is collected liquid. Cool down the temperature of the material to about 130°C, add 30 parts by weight of Dow Corning #3074 intermediate, 0.05 parts by weight of tetrabutyl titanate, control the temperature at 120°C-140°C for 1 hour; add 9 parts by weight of trimellitic anhydride, control The temperature is 120°C, react for 40 minutes; stop heating, cool naturally to 90°C, add 20 parts by weight of γ-butyrolactone, 9 parts by weight of triethanolamine, and 45 parts by weight of water and stir for 15 minutes, mix well and discharge to obtain product.

Embodiment 3

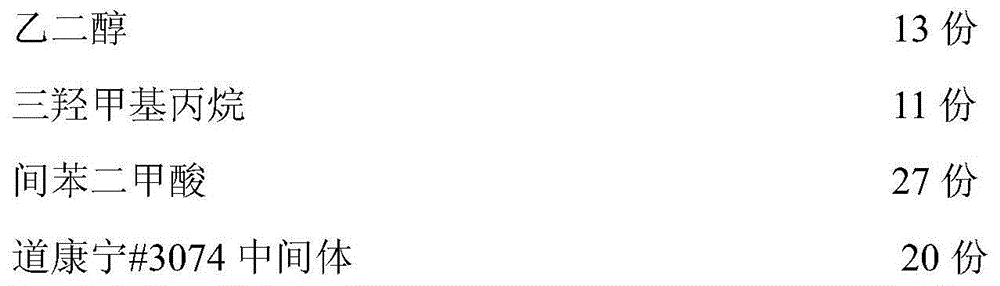

[0030] A kind of organosilicon modified waterborne polyester resin, proportioning by weight is as follows:

[0031]

[0032]

[0033] Preparation process: Take 13 parts by weight of ethylene glycol, 11 parts by weight of trimethylolpropane, and 27 parts by weight of isophthalic acid, and heat up to 120°C to dissolve; protect with nitrogen, start stirring, and control the temperature at 185°C-240°C °C until the theoretical weight part of condensate is collected. Cool down the temperature of the material to about 130°C, add 20 parts by weight of Dow Corning #3074 intermediate, 0.04 parts by weight of tetrabutyl titanate, control the temperature at 120°C-140°C for 1 hour; add 8 parts by weight of trimellitic anhydride, control The temperature is 120°C, react for 40min; stop heating, cool naturally to 90°C, add 20 parts by weight of γ-butyrolactone, 7 parts by weight of N,N-dimethylethanolamine, 45 parts by weight of water and stir for 15 minutes, mix After uniformity, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com