USY molecular sieve and preparation method thereof

A molecular sieve and molar ratio technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor hydrothermal stability, nano Y-type molecular sieves that cannot be widely promoted, and crystal channel topology collapse. , to achieve the effects of strong anti-coking ability, good catalytic activity and diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

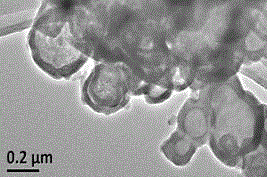

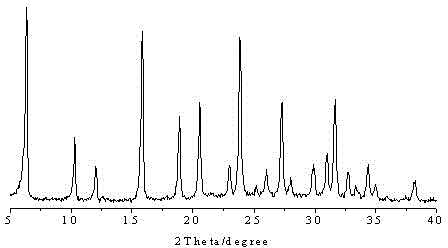

Image

Examples

Embodiment 1

[0026] (1) According to the molar ratio of n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=18.4:1:19.8:370, under stirring, add sodium aluminate, sodium hydroxide, water, and water glass to the beaker in turn to form a mixed solution, and then age at 30°C for 1 day to obtain the directing agent .

[0027] (2) According to the molar ratio of each material in the gel (excluding the added nano Y-type molecular sieve) is n (NaOH): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=14:1:24:520. Under the condition of stirring, add water, aluminum source, sodium hydroxide and water glass into the beaker in order to form a mixed solution, then add nano Y-type molecular sieve and the directing agent prepared in step (1), stir well Constant temperature crystallization at 100°C for 60 hours. Then after cooling, washing, suction filtration and drying, Y-Y composite molecular sieves are obtained, wherein the quality of the added nanometer Y-type molecular sieve accounts for 8wt% of t...

Embodiment 2

[0032] (1) According to the molar ratio of n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=18:1:19:350, under stirring, add sodium aluminate, sodium hydroxide, water, and water glass to the beaker in turn to form a mixed solution, and then age at 35°C for 1 day to prepare the directing agent .

[0033] (2) According to the molar ratio of each material in the gel (excluding the added nano Y-type molecular sieve) is n (NaOH): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=15:1:21:580. Under the condition of stirring, add water, sodium aluminate, sodium hydroxide and water glass into the beaker in turn to form a mixed solution, then add nano Y-type molecular sieve and the directing agent prepared in step (1), stir well and pour the condensed The glue was crystallized at a constant temperature of 95°C for 48 hours. Then after cooling, washing, suction filtration and drying, Y-Y composite molecular sieves are obtained, wherein the quality of the added nanometer Y-type mole...

Embodiment 3

[0038] (1) According to the molar ratio of n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=18:1:19:330, under stirring, add sodium aluminate, sodium hydroxide, water, and water glass to the beaker in turn to form a mixed solution, and then age at 50°C for 0.5 days to obtain the directing agent .

[0039] (2) According to the molar ratio of each material in the gel (excluding the added nano Y-type molecular sieve) is n (NaOH): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=15:1:24:600. Under the condition of stirring, add water, sodium aluminate, sodium hydroxide and water glass into the beaker in turn to form a mixed solution, then add nano Y-type molecular sieve and the directing agent prepared in step (1), stir well and pour the condensed The glue was crystallized at a constant temperature of 98° C. for 48 hours. Then after cooling, washing, suction filtration and drying, Y-Y composite molecular sieves are obtained, wherein the quality of the nano Y-type molecular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com