Method for synthesizing nitrogen-doped bismuth vanadate photocatalyst and application thereof

A photocatalyst, bismuth vanadate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of photocatalytic efficiency to be improved, and achieve fast reaction speed, great universality, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

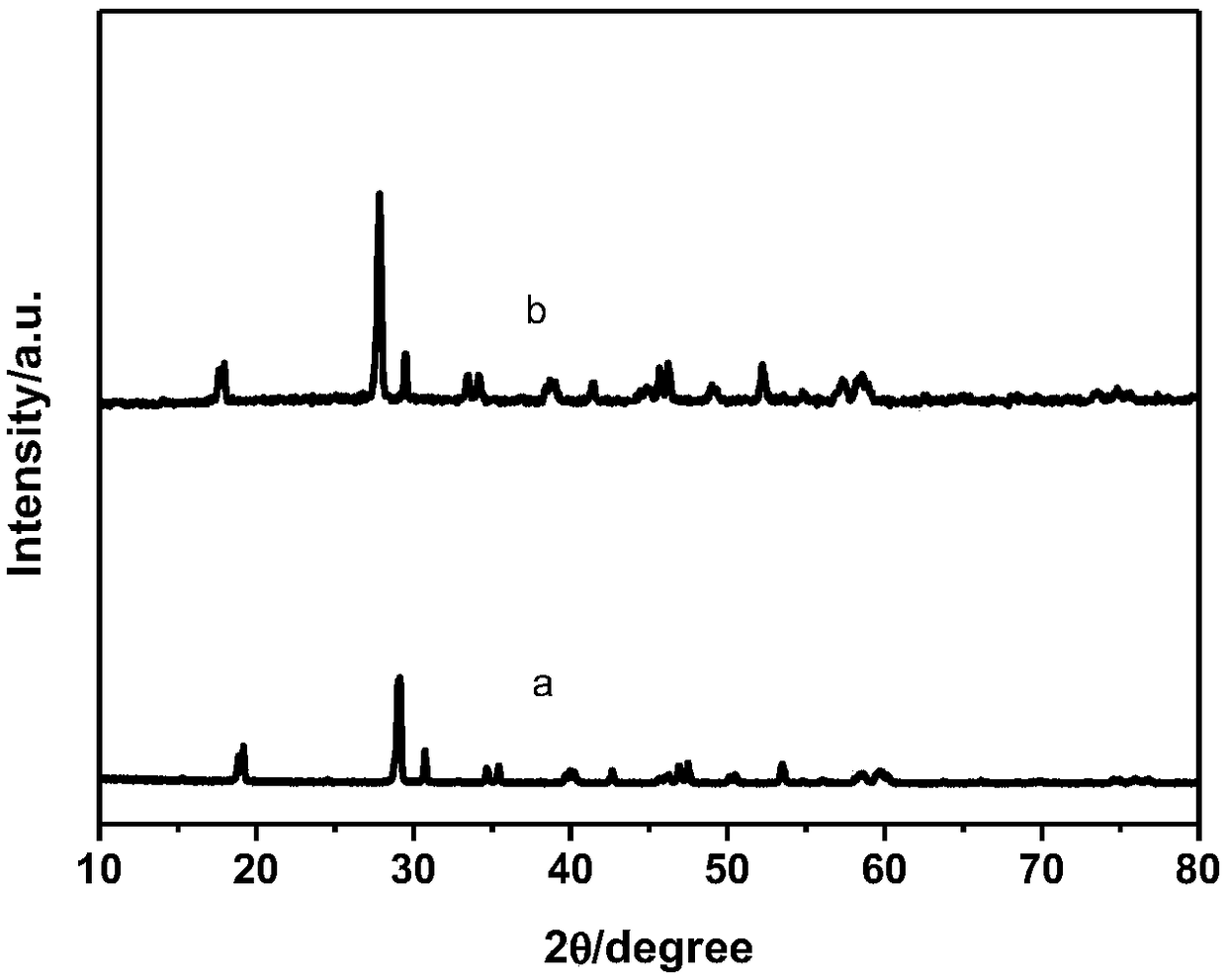

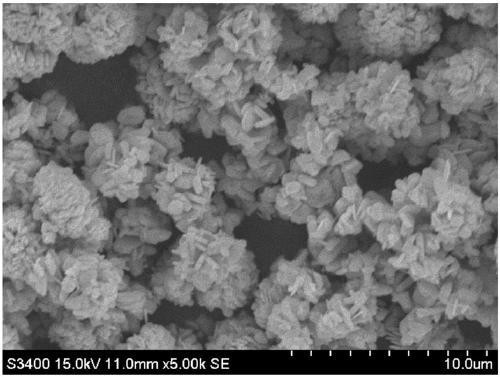

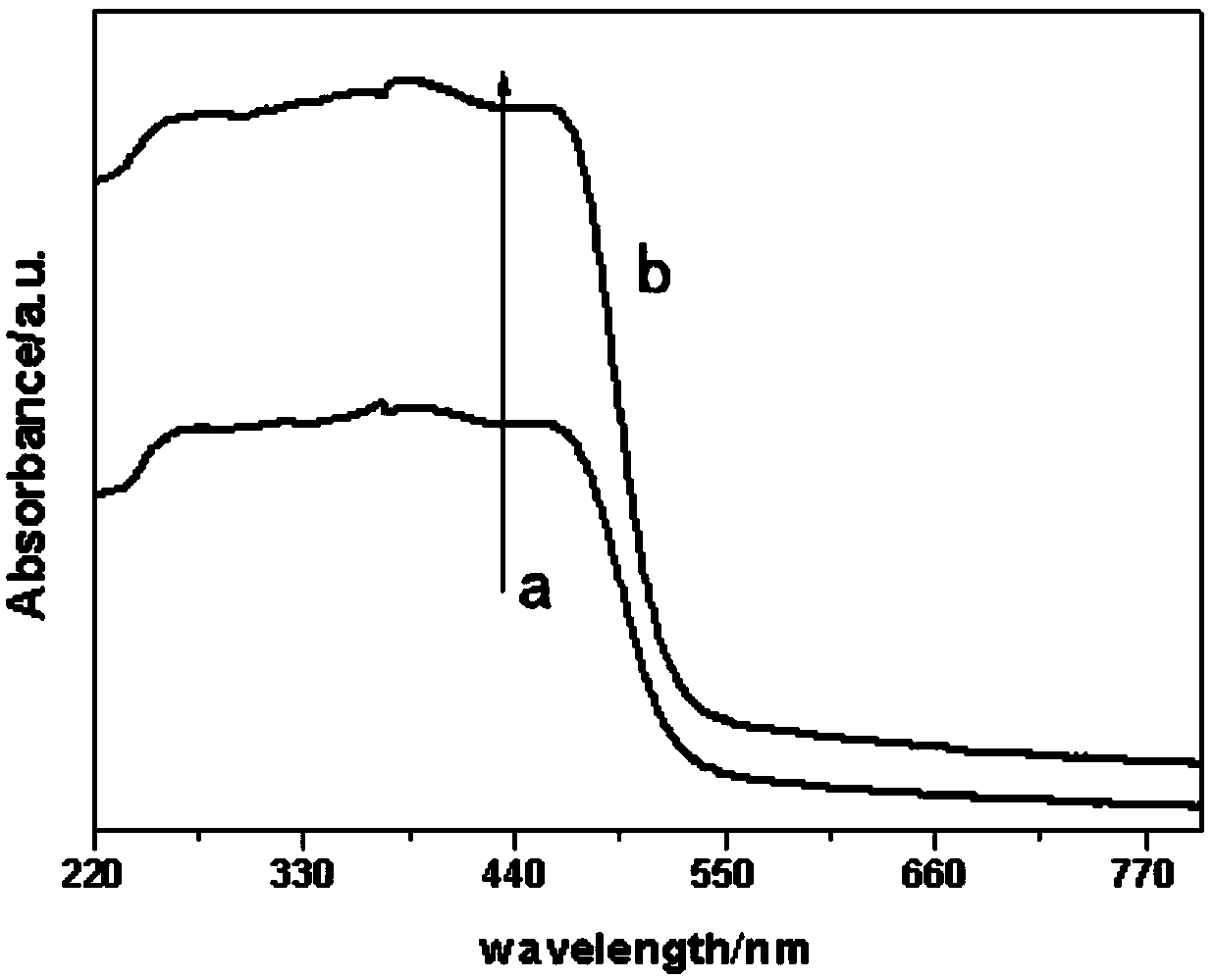

[0025] Embodiment 1: a kind of method of nitrogen-doped bismuth vanadate photocatalyst, comprises the following steps:

[0026] Step 1: Dissolve 2.5mmol bismuth nitrate pentahydrate in 2mol / L concentrated nitric acid, add a certain amount of polyvinylpyrrolidone, and stir magnetically for 30 minutes to obtain solution A; dissolve 2.5mmol ammonium metavanadate in 2mol / L ammonia solution , add urea according to the molar ratio of N to Bi of 0.5:1, and stir magnetically for 30 minutes to obtain solution B;

[0027] Step 2: Slowly add solution A to solution B, and continue magnetic stirring for 1 h after mixing. Add concentrated ammonia water dropwise to adjust the pH of the solution to about 7, sonicate for 30 minutes, and then perform magnetic stirring for 1 hour to obtain the precursor solution;

[0028] Step 3: Add the precursor solution into the reaction kettle lined with polytetrafluoroethylene, put the reaction kettle into the oven for heating, set the heating temperature ...

Embodiment 2

[0031] Embodiment 2: a kind of method of nitrogen-doped bismuth vanadate photocatalyst, comprises the following steps:

[0032] Step 1: Dissolve 2.5mmol bismuth nitrate pentahydrate in 2mol / L concentrated nitric acid, add a certain amount of polyvinylpyrrolidone, and stir magnetically for 30 minutes to obtain solution A; dissolve 2.5mmol ammonium metavanadate in 2mol / L ammonia solution , urea was added according to the molar ratio of N and Bi being 1:1, and magnetically stirred for 30 minutes to obtain solution B;

[0033] Step 2: Slowly add solution A to solution B, and continue magnetic stirring for 1 h after mixing. Add concentrated ammonia water dropwise to adjust the pH of the solution to about 7, sonicate for 30 minutes, and then perform magnetic stirring for 1 hour to obtain the precursor solution;

[0034] Step 3: Add the precursor solution into the reaction kettle lined with polytetrafluoroethylene, put the reaction kettle into the oven for heating, set the heating t...

Embodiment 3

[0037] Embodiment 3: a kind of method of nitrogen-doped bismuth vanadate photocatalyst, comprises the following steps:

[0038]Step 1: Dissolve 2.5mmol bismuth nitrate pentahydrate in 2mol / L concentrated nitric acid, add a certain amount of polyvinylpyrrolidone, and stir magnetically for 30 minutes to obtain solution A; dissolve 2.5mmol ammonium metavanadate in 2mol / L ammonia solution In, urea was added according to the molar ratio of N and Bi being 2:1, and magnetically stirred for 30 minutes to obtain solution B;

[0039] Step 2: Slowly add solution A to solution B, and continue magnetic stirring for 1 h after mixing. Add concentrated ammonia water dropwise to adjust the pH of the solution to about 7, sonicate for 30 minutes, and then perform magnetic stirring for 1 hour to obtain the precursor solution;

[0040] Step 3: Add the precursor solution into the reaction kettle lined with polytetrafluoroethylene, put the reaction kettle into the oven for heating, set the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com