Preparation method for thiamine modified bentonite

A technology of thiamine and bentonite, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve the problems of less research on the preparation of inorganic-organic composite modified bentonite, achieve significant modification effect and easy operation , Change the effect of layer spacing and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

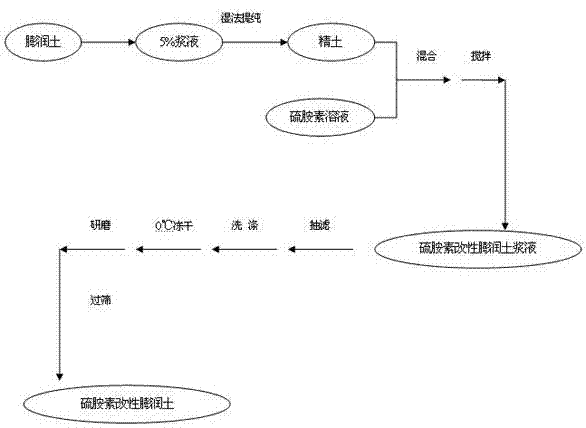

[0029] First, purify the original soil: make the original soil into a 5% soil suspension, stir for 20 minutes, and after standing for 5 minutes, use the siphon method to take the upper slurry, let it stand for 1 day, take the upper slurry and centrifuge, and the bottom paste soil Dry, grind, pass through a 0.074mm sieve, and set aside.

[0030] Then prepare modifier solution: use 0.1mol / L hydrochloric acid and analytically pure thiamine to prepare a mass concentration of 3.5g / L thiamine solution.

[0031] Finally, prepare thiamine-modified bentonite: take 100 mL of thiamine solution with a mass concentration of 3.5 g / L and mix it evenly with a certain quality of refined soil, stir for 60 minutes, filter with suction, wash, freeze-dry at 0 ° C, grind, pass 0.074 mm Sieve to obtain thiamine-modified soil.

[0032] The optimum preparation conditions of thiamine modified bentonite:

[0033] The concentration of bentonite slurry is 5%, the mass concentration of thiamine solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com