Package layer for organic electroluminescent device and its prepn method and application

A technology for electroluminescent devices and encapsulation layers, which is applied in the manufacture of electroluminescent light sources, electric solid-state devices, semiconductor/solid-state devices, etc., which can solve problems such as inability to achieve encapsulation effects, little improvement, and device aging, and improve flexibility. and water-oxygen barrier properties, improving life and mechanical properties, and reducing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

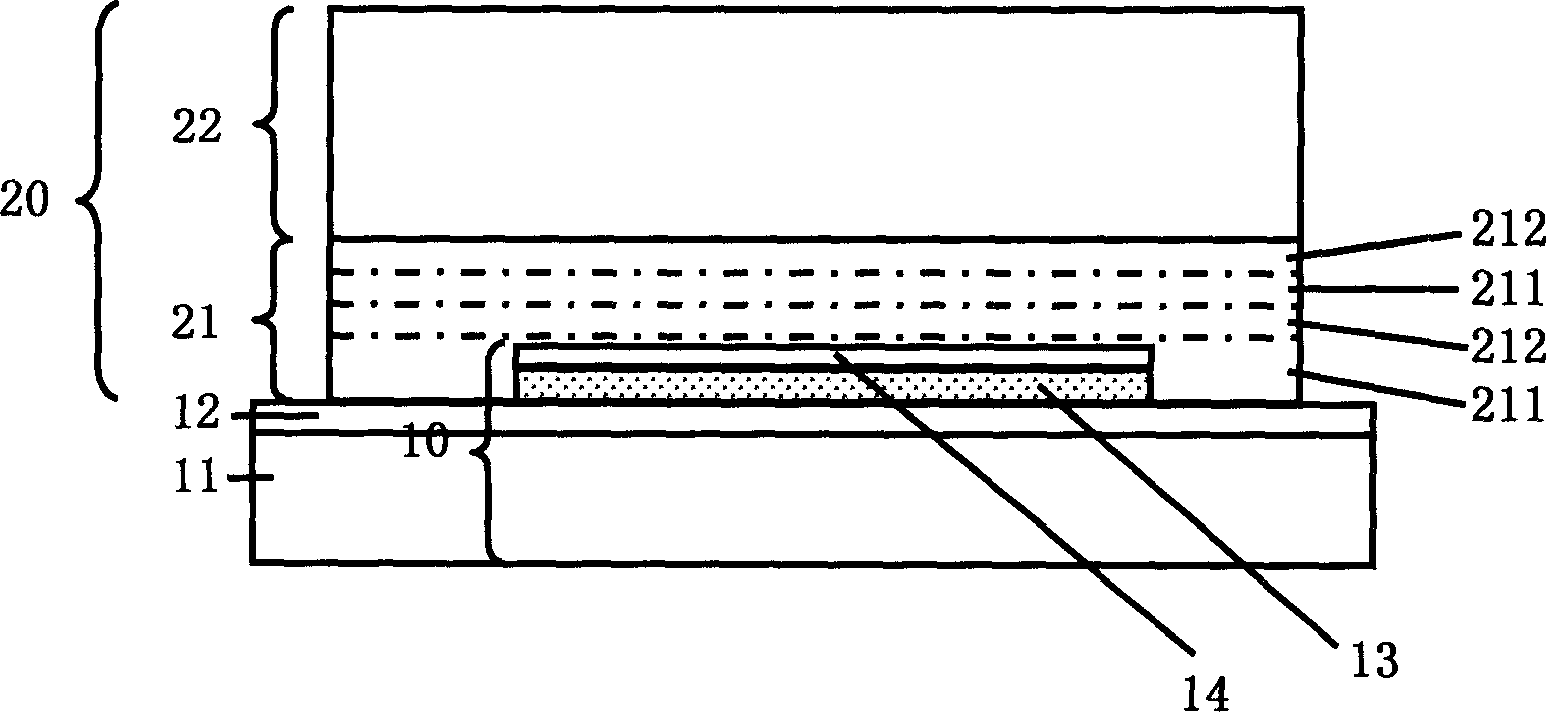

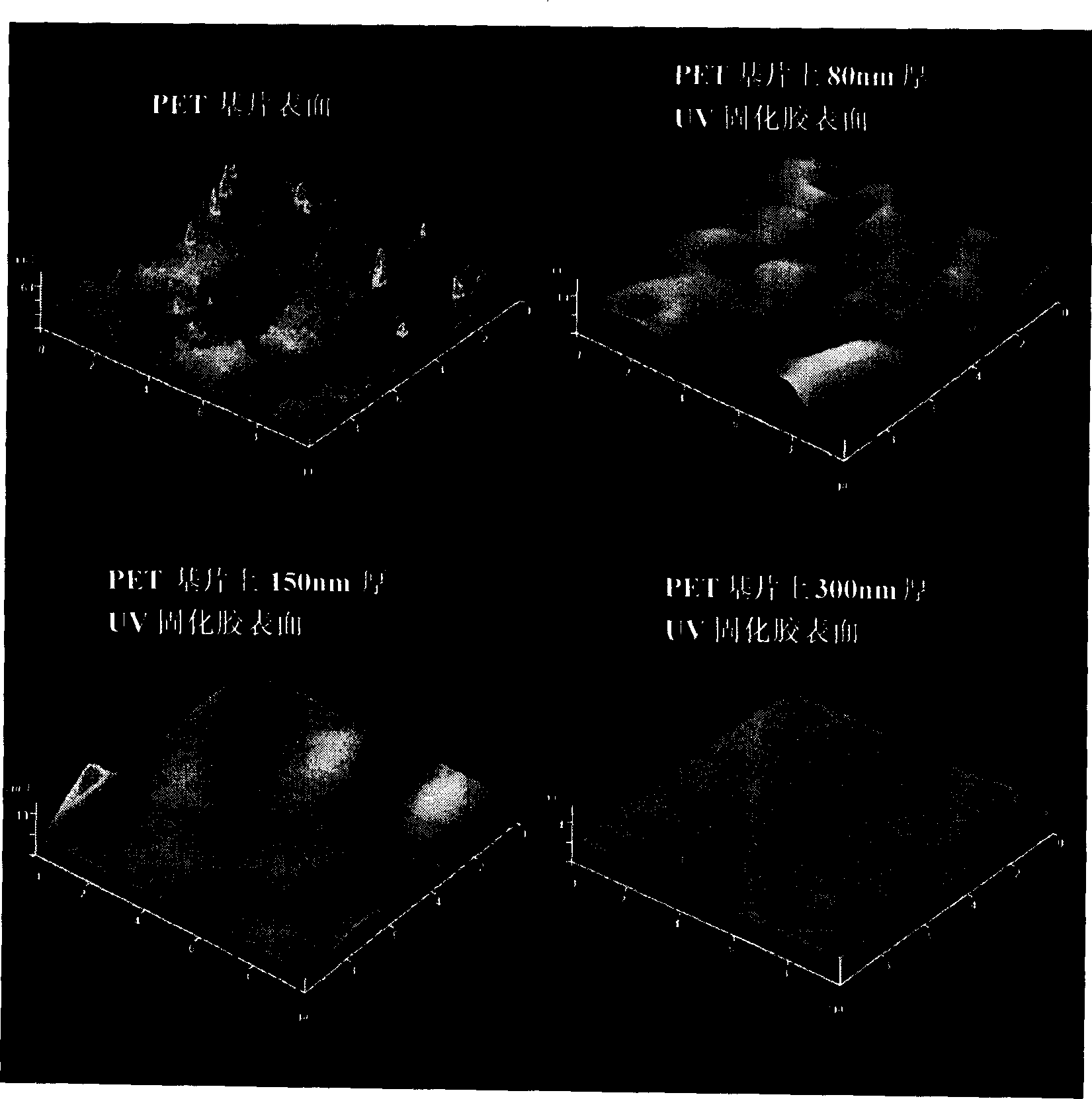

[0081] Place the OLEDs on the glass substrate in a vacuum coating machine and evacuate to 5×10 -4 pa. A layer of liquid UV-curable adhesive (UV STRCTL 352, Loctite Company) was vapor-deposited on the back of the device, and cured by ultraviolet radiation for 5 minutes. The UV-curable adhesive was in-situ polymerized into a flat solid film by ultraviolet irradiation. The film thickness was 300 nm. At a background pressure of 10 -4 ~10 -3Nitrogen gas was introduced under the condition of Pa, and the air pressure in the vacuum chamber was adjusted to 0.40Pa. The high-purity titanium target was used to sputter on the UV-curable adhesive at a DC power of 96W. The substrate temperature was controlled below 40°C, and the growth time was 10min. The thickness of the TiO thin film is 50nm. Repeat the above steps to prepare another cycle of UV curable glue / titanium nitride composite film layer. Finally, the inert gas nitrogen was introduced into the glove box, and a layer of liquid ...

Embodiment 2

[0083] Place the OLEDs on the glass substrate in a vacuum coating machine and evacuate to 4×10 -4 pa. A layer of liquid UV-curable adhesive (UV STRCTL 352, Loctite Company) was vapor-deposited on the back of the device, and cured by ultraviolet radiation for 5 minutes. The UV-curable adhesive was in-situ polymerized into a flat solid film by ultraviolet irradiation. The film thickness was 300 nm. At a background pressure of 10 -4 ~10 -3 Oxygen was introduced under the condition of Pa, and the air pressure in the vacuum chamber was adjusted to 0.40Pa. A high-purity aluminum target was used to sputter on the UV-curable adhesive at a DC power of 96W. The substrate temperature was controlled below 40°C, and the growth time was 10min. The film thickness of the aluminum thin film was 50 nm. Repeat the above steps to prepare another 2 cycles of UV curable adhesive / alumina composite film layers. Finally, the inert gas nitrogen was introduced into the glove box, and a layer of liq...

Embodiment 3

[0086] n

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com