Eucalyptus plate modifying method

A technology of board and eucalyptus, which is applied in the field of modification of eucalyptus board, can solve the problem of inability to solve the problem of fungal decay of wood board, and achieve the effect of improving anticorrosion performance, improving performance and purifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

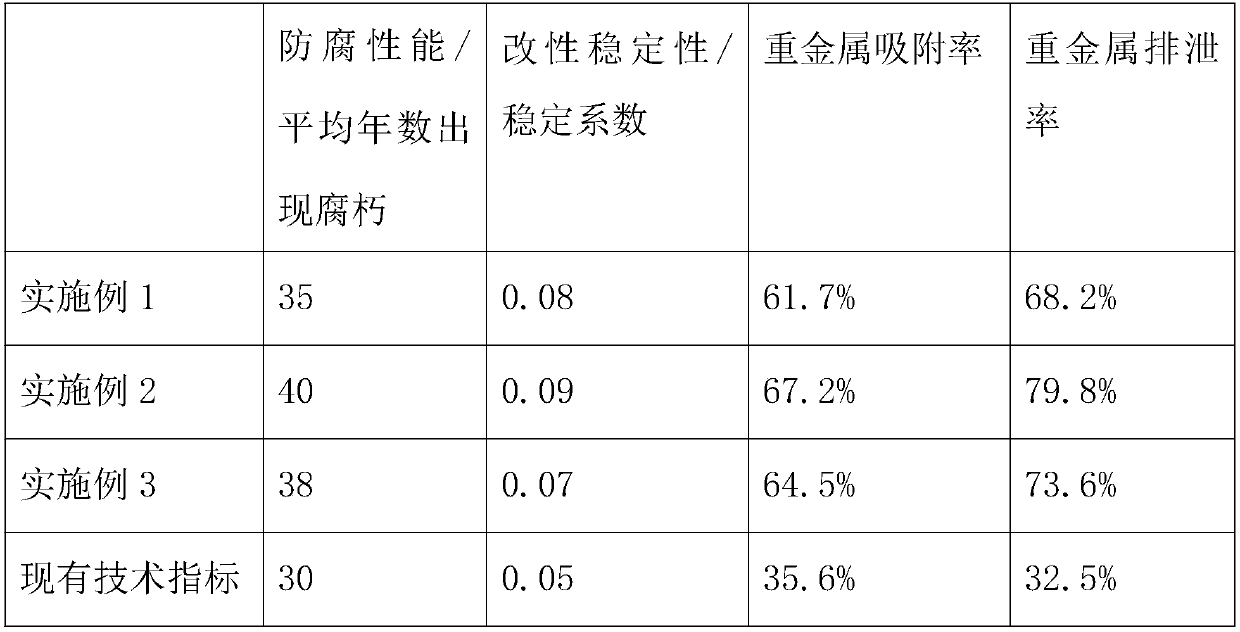

Examples

Embodiment 1

[0017] A method for modifying eucalyptus boards, the technological process comprising:

[0018] (1) Prepare modifier: Accurately weigh 20.0g of chitosan and place it in 400mL of 2% acetic acid solution, stir to dissolve, add 40mL of 2% glutaraldehyde, stir, keep at 50°C for 1 hour to obtain a yellow transparent chitosan hydrogel, and place it at room temperature 48h to get yellow transparent chitosan hydrogel, add chitosan hydrogel, activator, catalyst and other additives in distilled water, take 1L distilled water as standard, chitosan hydrogel 50mL, activator 10g, catalyst 8g and other additives 20g, the ratio of other additives is: 50% thickener and 50% stabilizer, add acid-base buffer while stirring, adjust the pH value of the solution between 6.5 to form a uniform solution;

[0019] (2) Impregnation of eucalyptus boards: using traditional vacuum pressurization equipment for wood preservative treatment, the full-cell method is used to soak the eucalyptus boards, and the eu...

Embodiment 2

[0022] A method for modifying eucalyptus boards, the technological process comprising:

[0023] (1) Preparation of modifier: Accurately weigh 35.0g of chitosan and place it in 400mL of 3% acetic acid solution, stir to dissolve, add 60mL of 2% glutaraldehyde, stir, and keep the temperature at 52°C for 1.5h to obtain a yellow transparent chitosan hydrogel, room temperature Place 48h to get yellow transparent chitosan hydrogel, add chitosan hydrogel, activator, catalyst and other additives in distilled water, take 1L distilled water as standard, chitosan hydrogel 80mL, activator 12g, catalyst 10g and others 25g of additives, the proportioning of other additives is: 60% thickener and 40% stabilizer, add acid-base buffer while stirring, adjust the pH value of the solution between 6.8 to form a uniform solution;

[0024] (2) Impregnation of eucalyptus boards: using traditional vacuum pressurization equipment for wood preservative treatment, the full-cell method is used to soak the e...

Embodiment 3

[0027] A method for modifying eucalyptus boards, the technological process comprising:

[0028] (1) Preparation of modifier: Accurately weigh 50.0g of chitosan, place it in 400mL of 5% acetic acid solution, stir to dissolve, add 80mL of 2% glutaraldehyde, stir, keep at 55°C for 2h to obtain a yellow transparent chitosan hydrogel, and place it at room temperature 48h to get yellow transparent chitosan hydrogel, add chitosan hydrogel, activator, catalyst and other additives in distilled water, take 1L distilled water as standard, chitosan hydrogel 100mL, activator 15g, catalyst 12g and other additives 30g, the ratio of other additives is: 70% thickener and 30% stabilizer, add acid-base buffer while stirring, adjust the pH value of the solution between 7.2 to form a uniform solution;

[0029] (2) Impregnation of eucalyptus boards: using traditional vacuum pressurization equipment for wood preservative treatment, the full-cell method is used to soak the eucalyptus boards, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com