Method for synthesizing carbon-doped BiVO4 photocatalyst by using microwave hydrothermal method

A microwave hydrothermal method and photocatalyst technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of high carrier recombination rate, low quantum efficiency, and limited applications. Achieve the effect of low cost, simple operation and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

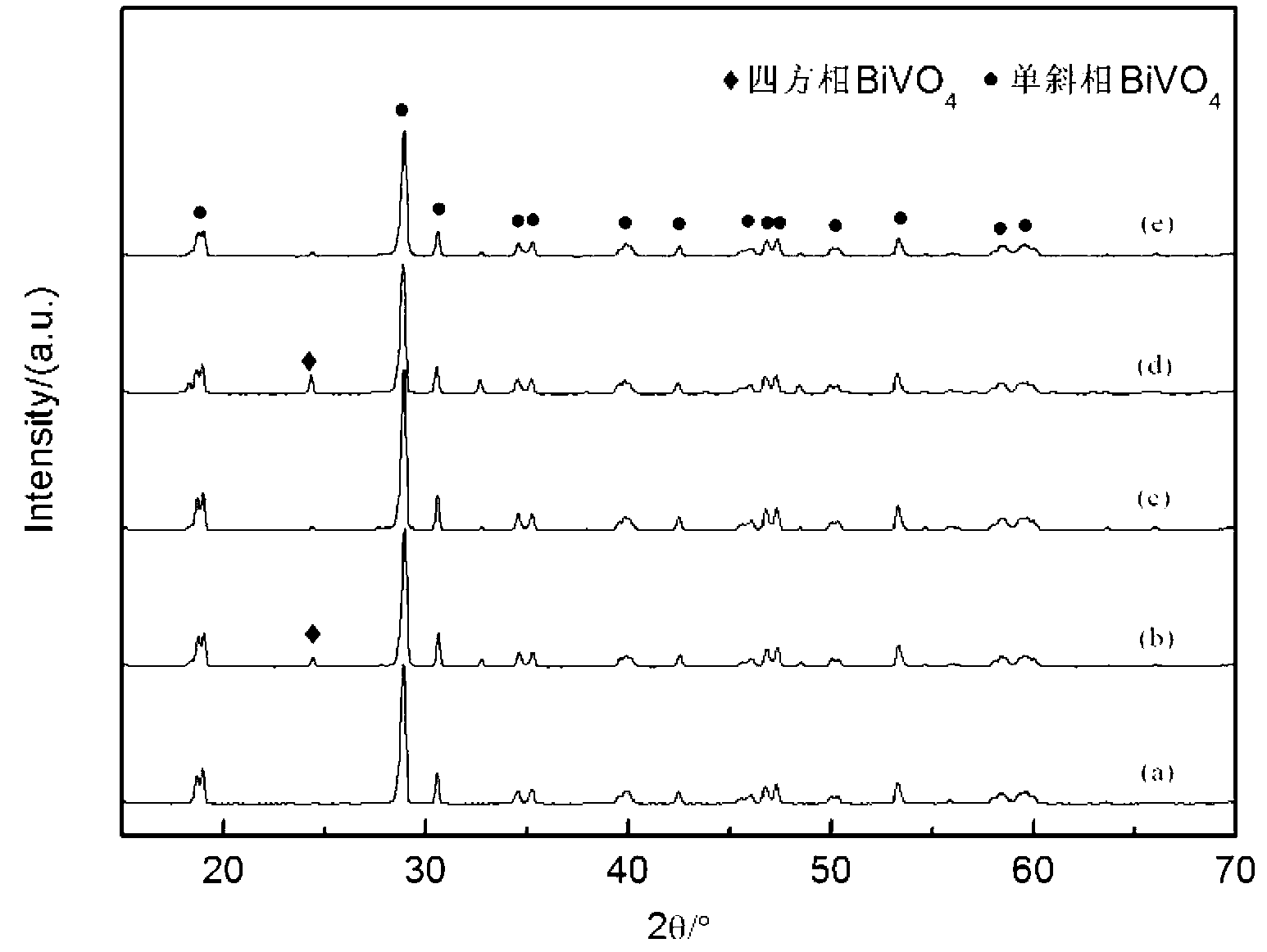

[0028] Synthesis of carbon-doped BiVO by a microwave hydrothermal method 4 A photocatalyst method comprising the steps of:

[0029] Step 1: Add 0.01mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 25ml deionized water, and stirred for 40min to obtain a bismuth salt solution, and 0.01mol NH 4 VO 3 Dissolve in 25ml of deionized water at 90°C, heat and stir for 30 minutes to obtain a vanadium salt solution, mix the bismuth salt solution and vanadium salt solution according to the molar ratio of Bi:V=1:1 to form a mixed solution;

[0030] Step 2: Dilute glucose according to C 6 h 12 o 6 : Bi(NO 3 ) 3 ·5H 2 Add the molar ratio of O=0.01:1 to the mixed solution prepared in step 1, and magnetically stir for 20 minutes to form a precursor;

[0031] Step 3: Put the precursor into a polytetrafluoroethylene-lined reaction kettle, put the reaction kettle into a microwave hydrothermal instrument, and select the microwave temperature control mode: from room temperature to 100°C, with a mic...

Embodiment 2

[0033] Synthesis of carbon-doped BiVO by a microwave hydrothermal method 4 A photocatalyst method comprising the steps of:

[0034] Step 1: Add 0.01mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 25ml deionized water, and stirred for 40min to obtain a bismuth salt solution, and 0.01mol NH 4 VO 3 Dissolve in 25ml of deionized water at 90°C, heat and stir for 30 minutes to obtain a vanadium salt solution, mix the bismuth salt solution and vanadium salt solution according to the molar ratio of Bi:V=1:1 to form a mixed solution;

[0035] Step 2: Dilute glucose according to C 6 h 12 o 6 : Bi(NO 3 ) 3 ·5H 2 The molar ratio of O=0.05:1 was added to the mixture, and magnetically stirred for 20 minutes to form a precursor;

[0036] Step 3: Put the precursor into a polytetrafluoroethylene-lined reaction kettle, put the reaction kettle into a microwave hydrothermal instrument, and select the microwave temperature control mode: from room temperature to 100°C, with a microwave power of...

Embodiment 3

[0038] Synthesis of carbon-doped BiVO by a microwave hydrothermal method 4 A photocatalyst method comprising the steps of:

[0039] Step 1: Add 0.01mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 25ml deionized water, and stirred for 40min to obtain a bismuth salt solution, and 0.01mol NH 4 VO 3 Dissolve in 25ml of deionized water at 90°C, heat and stir for 30 minutes to obtain a vanadium salt solution, mix the bismuth salt solution and vanadium salt solution according to the molar ratio of Bi:V=1:1 to form a mixed solution;

[0040] Step 2: Dilute glucose according to C 6 h 12 o 6 : Bi(NO 3 ) 3 ·5H 2 Add the molar ratio of O=0.10:1 into the mixture, and stir it magnetically for 20 minutes to form a precursor;

[0041] Step 3: Put the precursor into a polytetrafluoroethylene-lined reaction kettle, put the reaction kettle into a microwave hydrothermal instrument, and select the microwave temperature control mode: from room temperature to 100°C, with a microwave power of 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com