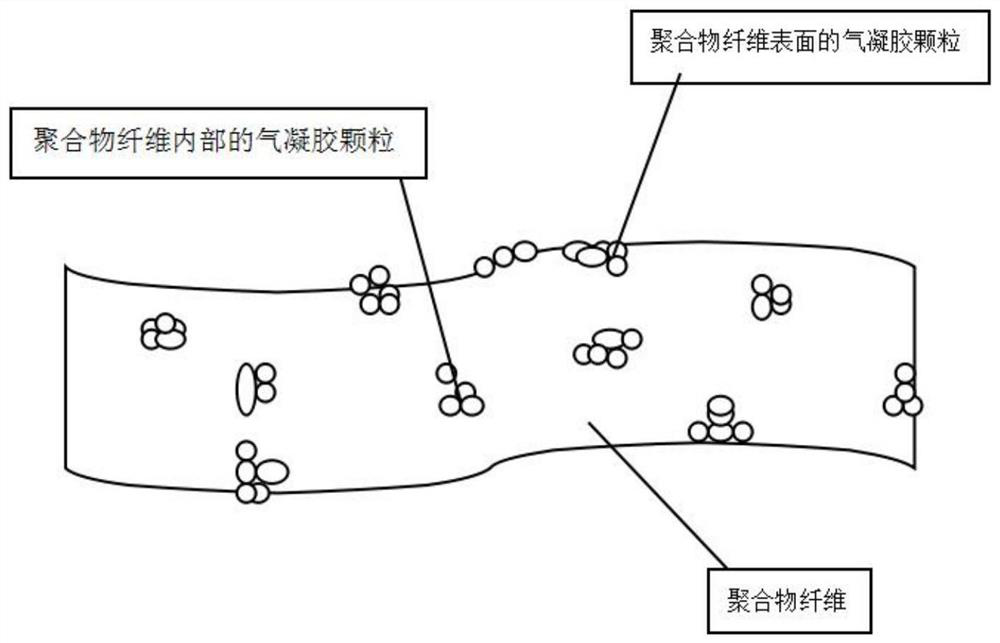

Modified polymer fibers as well as preparation method and application thereof

A technology of polymers and polymer particles, applied in the direction of single-component synthetic polymer rayon, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems such as no airgel reports, etc. The method is simple and easy to improve Production efficiency, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides the preparation method of the modified polymer fiber described in the technical scheme, comprising the following steps:

[0037] Feed polymer particles and airgel particles at the same time, carry out extrusion blending, and obtain a melt;

[0038] Spinning the melt to obtain filaments;

[0039] The filaments are drawn and formed to obtain modified polymer fibers.

[0040] In the invention, polymer particles and airgel particles are simultaneously fed, extruded and blended to obtain a melt.

[0041] In the present invention, before the feeding, the present invention preferably pretreats the polymer particles, the present invention has no special limitation on the pretreatment method of the polymer particles, according to the type of polymer particles according to the present invention Preprocessing can be performed by methods well known in the field. In an embodiment of the present invention, the pretreatment method is preferably drying...

Embodiment 1

[0066] Pre-crystallize polyester chips in an ebullating bed at a temperature of 180°C for 15 minutes to obtain pre-crystallized chips;

[0067] Put the pre-crystallized chips into a drying tower, and dry them at a drying temperature of 190° C. for 5 hours to obtain dried polyester chips;

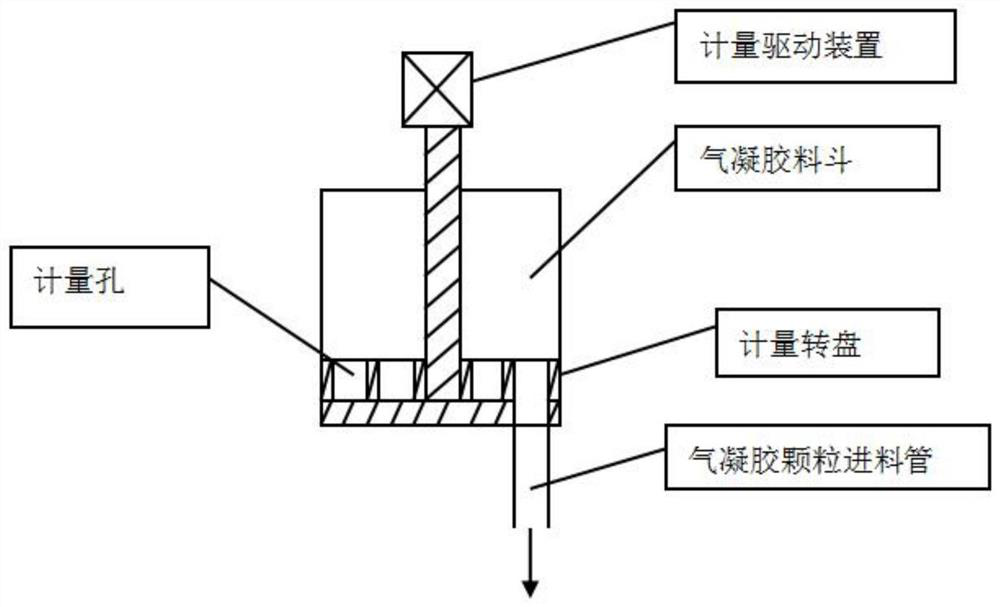

[0068] Silica airgel (particle size 23μm) was added figure 2 The shown disc-type volumetric metering device feeder (the mass percentage of the silica airgel accounting for the polyester chip is 10%), the polyester chip after drying and the metered silica airgel are simultaneously Enter the screw extruder for melting, the obtained melt is filtered to remove impurities, enter the metering pump in the spinning box for metering, and evenly distribute to each spinneret according to the mass (the hole shape of the spinneret is circular), and spray Silk to obtain filaments; wherein, the aperture of the spinneret used is 0.35mm, and the aspect ratio is 2.3; the screw temperature is respectively 28...

Embodiment 2

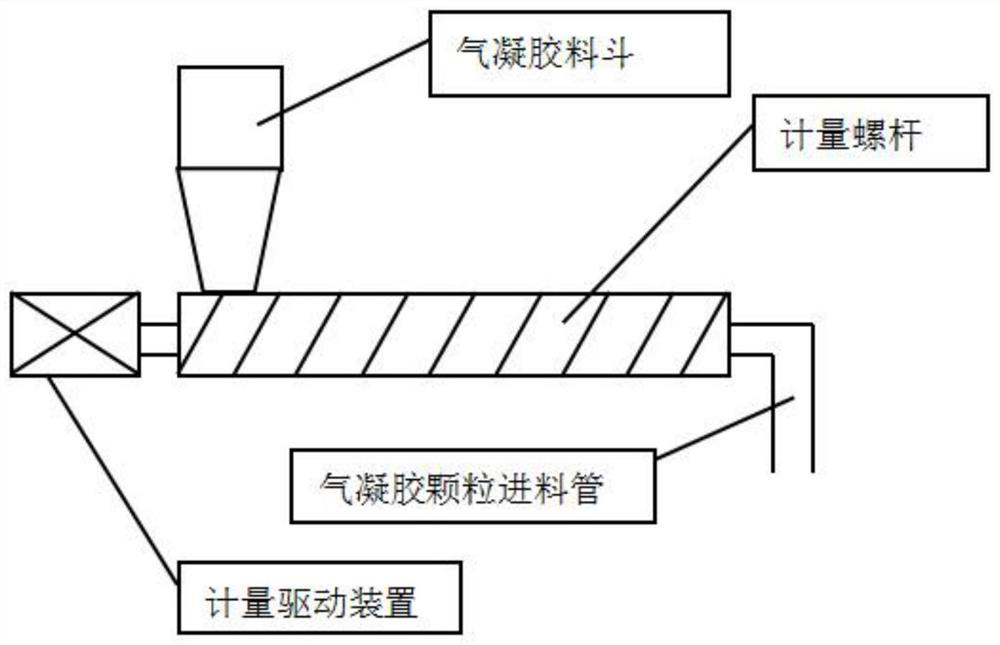

[0075] Put PA6 slices with a relative viscosity of 2.5 into a drying tower, and dry them at a drying temperature of 60°C for 4 hours to obtain dried PA6 slices;

[0076] Titanium dioxide airgel (particle size is 23 μm) is added to the feeder of the weight loss metering device (the mass percentage of the titanium dioxide airgel accounting for the PA6 slice is 12%);

[0077] The dried PA6 slices and the metered titanium dioxide airgel are melted into the screw extruder at the same time, and the obtained melt is filtered to remove impurities, and then enters the metering pump in the spinning box for metering, and is evenly distributed to each spinneret according to the mass. plate (the hole shape of the spinneret is circular), and spin to obtain filaments; wherein, the hole diameter of the spinneret used is 0.3mm, and the aspect ratio is 1.35; the screw temperature is 270°C in the first zone and 270°C in the second zone. , The third zone is 275°C, the fourth zone is 275°C, the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com