Microwave plasma-based treatment method and system for surface modification of copper indium gallium selenide (CIGS)

A microwave plasma, copper indium gallium selenide technology, applied in ion implantation plating, metal material coating process, vacuum evaporation plating, etc., can solve the problem of uneven distribution of Ga content along the depth, and achieve the reduction of unevenness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

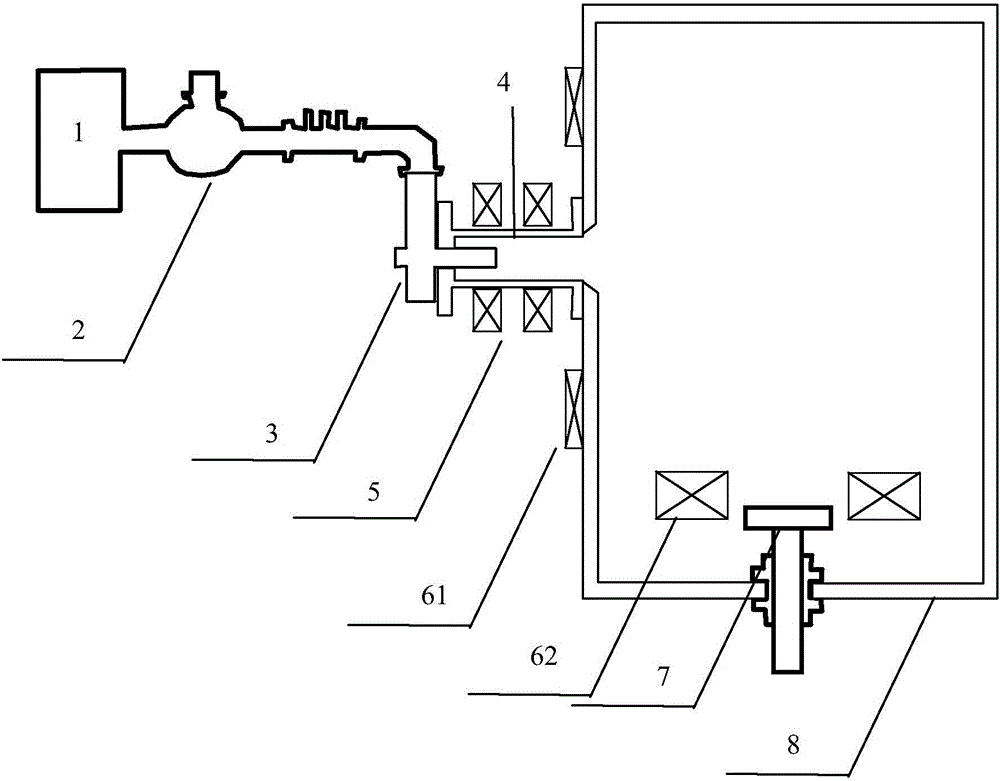

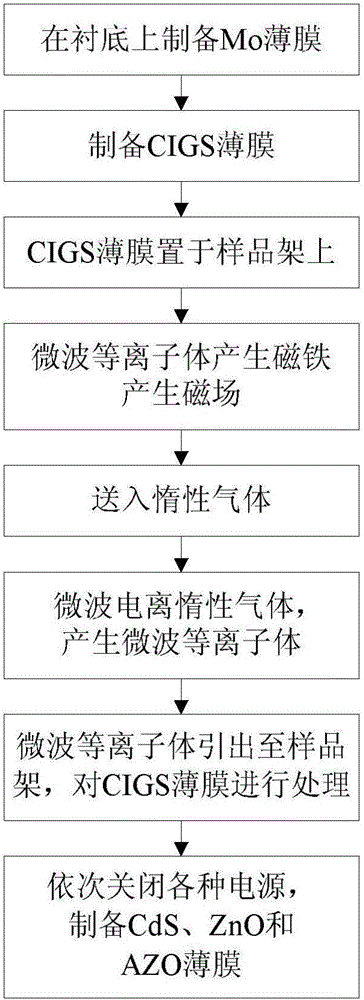

[0035] Such as figure 1 As shown, the treatment system for surface modification of copper indium gallium selenide in this embodiment includes: microwave power source 1, transmission system 2, waveguide to coaxial 3, microwave plasma generation chamber 4, microwave plasma generation magnetic field coil 5 , a deflection yoke, a sample holder 7, and a vacuum chamber 8; wherein, the microwave power source 1 emits microwaves; the microwaves are transmitted to the waveguide-to-coaxial 3 through the transmission system 2; the waveguide-to-coaxial 3 feeds the microwaves into the microwave plasma generation chamber 4; The microwave plasma generation chamber 4 is wound with a microwave plasma generation magnetic field coil 5; the microwave plasma generation chamber 4 is connected to the vacuum chamber 8; the vacuum chamber 8 is provided with a sample hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com