A kind of polyester amide and preparation method thereof

A polyester amide and amide technology, applied in the field of polymer compounds, can solve problems such as easy yellowing, and achieve the effects of low yellow index, optimized performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

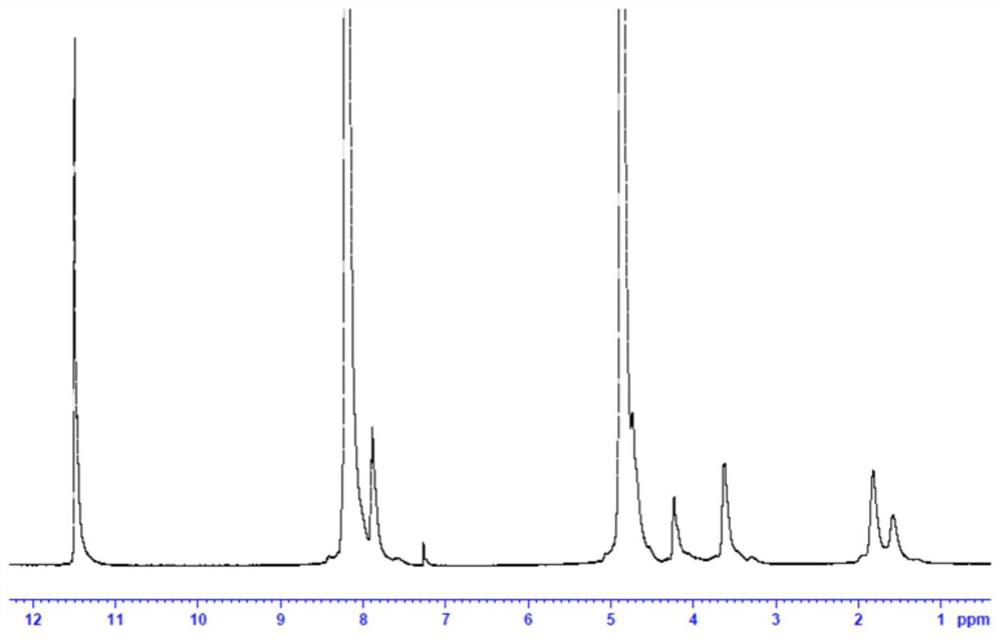

AI Technical Summary

Problems solved by technology

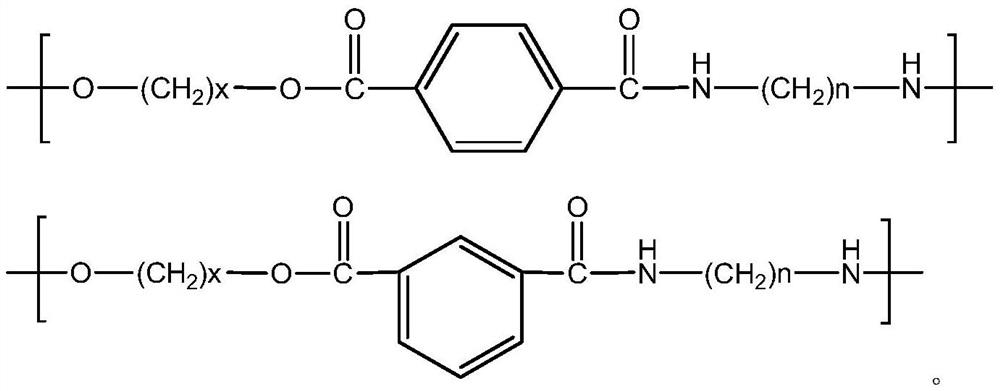

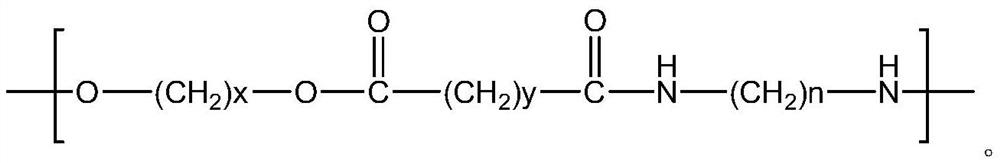

Method used

Image

Examples

Embodiment 1

[0043] Synthesis of Nylon Salt (PA56 Salt)

[0044] Under nitrogen protection, weigh 3880G of pure water and add it to a 10L reactor, slowly add 1586G of pentamethylenediamine, and then slowly add 2206G of adipic acid. The exotherm is obvious during the feeding process, so ensure that the temperature in the kettle does not exceed 65 °C. Under nitrogen protection, the oil bath was heated to keep the temperature in the kettle at 60° C., and continued stirring to obtain a clear pale yellow salt solution, which was detected with a pH meter (pH was 7.5). After the reaction was completed, the temperature was lowered to separate out the solid, and an appropriate amount of ethanol was added to fully separate out the solid. The precipitated solid was filtered under reduced pressure and washed with cold water to obtain the first white solid product. The first product was dried under vacuum at 80°C for 15 hours to obtain 3350G of white solid PA56 salt.

Embodiment 2

[0046] Synthesis of Nylon Salt (PA66 Salt)

[0047]Under nitrogen protection, weigh 3550G of pure water and add it to a 10L reactor, then add 1657G of hexamethylenediamine, and finally slowly add 2060G of adipic acid. The exotherm is obvious during the feeding process, so ensure that the temperature in the kettle does not exceed 65 °C. Under nitrogen protection, the oil bath was heated to keep the temperature in the kettle at 62°C, and the stirring was continued to obtain a clear pale yellow salt solution. The pH meter was used to detect the salt solution (pH was 7.2). After the reaction was completed, the temperature was lowered to separate out the solid, and an appropriate amount of ethanol was added to fully separate out the solid. The precipitated solid was filtered under reduced pressure and washed with cold water to obtain the first white solid product. The first product was vacuum-dried at 80°C for 15 hours to obtain 3345G of white solid PA66 salt.

Embodiment 3

[0049] Synthesis of Nylon Salt (PA6T Salt)

[0050] Under nitrogen protection, weigh 3950G of pure water and add it to a 10L reactor, then add 1345G of hexamethylenediamine, and finally slowly add 1890G of terephthalic acid (PTA). Under nitrogen protection, the oil bath was heated to keep the temperature in the kettle at 65° C., and continued stirring to obtain a clear pale yellow salt solution, which was detected with a pH meter (pH was 7.5). After the reaction was completed, the temperature was lowered to separate out the solid, and an appropriate amount of ethanol was added to fully separate out the solid. The precipitated solid was filtered under reduced pressure and washed with cold water to obtain the first white solid product. The first product was dried under vacuum at 80°C for 15 hours to obtain 2690G of white solid PA6T salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com