A preparation method of poly-3-methylthiophene-coated nano-nickel-zinc ferrite particle magnetic liquid

A technology of nickel-zinc ferrite and zinc ferrite, applied in the direction of magnetic liquid, inorganic material magnetism, etc., to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

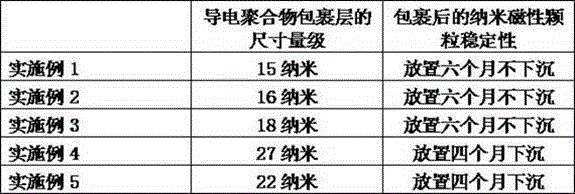

Examples

Embodiment 1

[0013] A poly-3-methylthiophene-coated nano-nickel-zinc ferrite particle magnetic liquid, the preparation method of which is:

[0014] A. Put 31.32gFe(NO 3 ) 3 9H 2 O, 12.89gNi(NO 3 ) 2 ·6H 2 O, 24.57gZn(NO 3 ) 2 ·6H 2 O was dissolved in 250ml water to make a solution, and then 12.24g FeSO 4 ·7H 2 O was dissolved in 250ml water to form a solution, the above two solutions were poured into a three-necked flask for dissolution, and then 70mL of concentrated ammonia water was added, stirred for 20 minutes, then magnetically separated for 4 hours, washed with deionized water until pH = 7.0, and 82.02g Fe ( NO 3 ) 3 9H 2 O is dissolved in 500ml water to form Fe(NO 3 ) 3 9H 2 O solution, the Fe(NO 3 ) 3 9H 2 The O solution was poured into the washed solution and boiled for 30 minutes, magnetically separated until naturally cooled to room temperature, poured off the supernatant, washed repeatedly with deionized water until neutral, dried naturally in a vacuum drying ...

Embodiment 2

[0019] A poly-3-methylthiophene-coated nano-nickel-zinc ferrite particle magnetic liquid, the preparation method of which is:

[0020] A. Put 31.32gFe(NO 3 ) 3 9H 2 O, 12.89gNi(NO 3 ) 2 ·6H 2 O, 24.57gZn(NO 3 ) 2 ·6H 2 O was dissolved in 250ml water to make a solution, and then 12.24g FeSO 4 ·7H 2 O was dissolved in 250ml water to form a solution, the above two solutions were poured into a three-necked flask for dissolution, and then 70mL of concentrated ammonia water was added, stirred for 25 minutes, then magnetically separated for 5 hours, washed with deionized water until pH = 7.0, and 82.02g Fe ( NO 3 ) 3 9H 2 O is dissolved in 500ml water to form Fe(NO 3 ) 3 9H 2 O solution, the Fe(NO 3 ) 3 9H 2 The O solution was poured into the washed solution and boiled for 35 minutes, magnetically separated until naturally cooled to room temperature, poured off the supernatant, washed repeatedly with deionized water until neutral, dried naturally in a vacuum drying ...

Embodiment 3

[0025] A poly-3-methylthiophene-coated nano-nickel-zinc ferrite particle magnetic liquid, the preparation method of which is:

[0026] A. Put 31.32gFe(NO 3 ) 3 9H 2 O, 12.89gNi(NO 3 ) 2 ·6H 2 O, 24.57gZn(NO 3 ) 2 ·6H 2 O was dissolved in 250ml water to make a solution, and then 12.24g FeSO 4 ·7H 2 O was dissolved in 250ml water to form a solution, the above two solutions were poured into a three-necked flask for dissolution, and then 70mL of concentrated ammonia water was added, stirred for 30 minutes, then magnetically separated for 6 hours, washed with deionized water until pH = 7.0, and 82.02g Fe ( NO 3 ) 3 9H 2 O is dissolved in 500ml water to form Fe(NO 3 ) 3 9H 2 O solution, the Fe(NO 3 ) 3 9H 2 The O solution was poured into the washed solution and boiled for 40 minutes, magnetically separated until naturally cooled to room temperature, poured off the supernatant, washed repeatedly with deionized water until neutral, dried naturally in a vacuum drying di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com