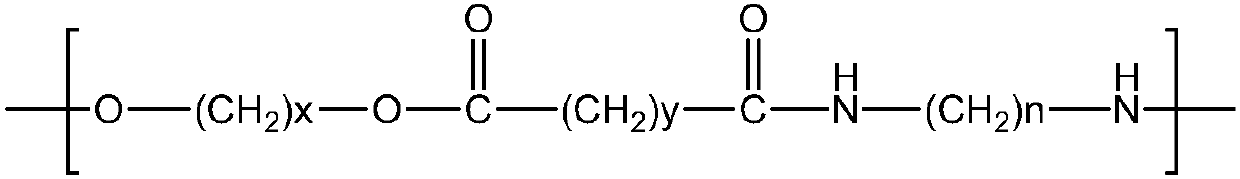

Polyester amide hot melt adhesive and preparation method thereof

A polyester amide and hot melt adhesive technology, applied in the direction of adhesives, etc., can solve the problems of low yellow index of polyester amide hot melt adhesive, low peel strength loss rate, poor water resistance of polyester amide, etc., and achieve low peel strength loss rate. , the effect of high peel strength and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 800G of hexanediol and 1.5KG of dodecanedioic acid into a 5L reactor. Under the protection of nitrogen, start heating to the temperature in the kettle of 130° C., start stirring, and under the protection of nitrogen, add 1.5 g of tetraisopropyl titanate. After the mixture becomes a clear liquid, continue to heat up and react. In the presence of nitrogen flow, when the temperature in the kettle reaches 160°C, start to drain water until the pressure in the kettle drops to 0 (or the pressure of nitrogen flow), and the temperature rises slowly to 190°C, and drain at normal pressure under the protection of nitrogen flow until no fraction is discharged. . The temperature was lowered, the temperature in the kettle was lowered to 140° C., and the material was discharged while it was hot under nitrogen pressure to obtain a white solid hexylene glycol dodecanedioate oligomer.

[0039] Add 1.5KG of pure water and 240G of lactic acid into a 10L polymerization kettle, and slo...

Embodiment 2

[0041] Add 850G of hexanediol, 8.5G of ethylene glycol antimony, and 1.45KG of sebacic acid in a 5L polymerization kettle. Nitrogen was replaced three times, and under the condition of nitrogen protection, heating was started. When the temperature in the kettle rose to 125°C, keep the temperature for 10 minutes and start stirring. Continue to heat up the reaction, when the temperature in the kettle reaches 145° C., start to drain water until the pressure in the kettle drops to 0 (or nitrogen flow pressure), and drain water for 3 hours altogether. The temperature in the kettle rose to 190°C, and the water was drained under normal pressure under the protection of nitrogen flow until no distillate was discharged. The temperature in the kettle was lowered to 145° C., and then the material was discharged while it was hot under the protection of nitrogen. The hexanediol sebacate oligomer was obtained as a white solid.

[0042] Add 2KG of pure water, 4KG of PA1010 salt (Xinglong N...

Embodiment 3

[0044] Add 8KG of pure water and 10% of PA66 salt (Henan Shenma Nylon Chemical Industry Co., Ltd.) into the polycondensation kettle of the 30L polymerization kettle. After nitrogen replacement three times, under the condition of nitrogen protection, start to heat up. When the temperature in the still rose to 205°C, the pressure in the still was 16KG, and the water outlet valve was opened to start draining. Control the water output, ensure that the pressure in the kettle is 16KG, and drain for 3 hours. Then continue to drain water until the pressure in the kettle drops to 0 (or nitrogen flow pressure), and the temperature in the kettle rises to about 235° C., which takes 3 hours. Then the material was kept stirring under the condition of nitrogen protection and the temperature in the kettle at 185°C.

[0045]In the esterification kettle of the 30L polymerization kettle, add 3.2KG of hexanediol and 3.5KG of adipic acid. Under the protection of nitrogen, it was heated to a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com