Thermoplastic polyimide with excellent comprehensive performance and preparation method and application thereof

A polyimide and comprehensive performance technology, which is applied in the field of thermoplastic polyimide and its preparation, can solve the problems such as the difficulty of having both melting processability and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

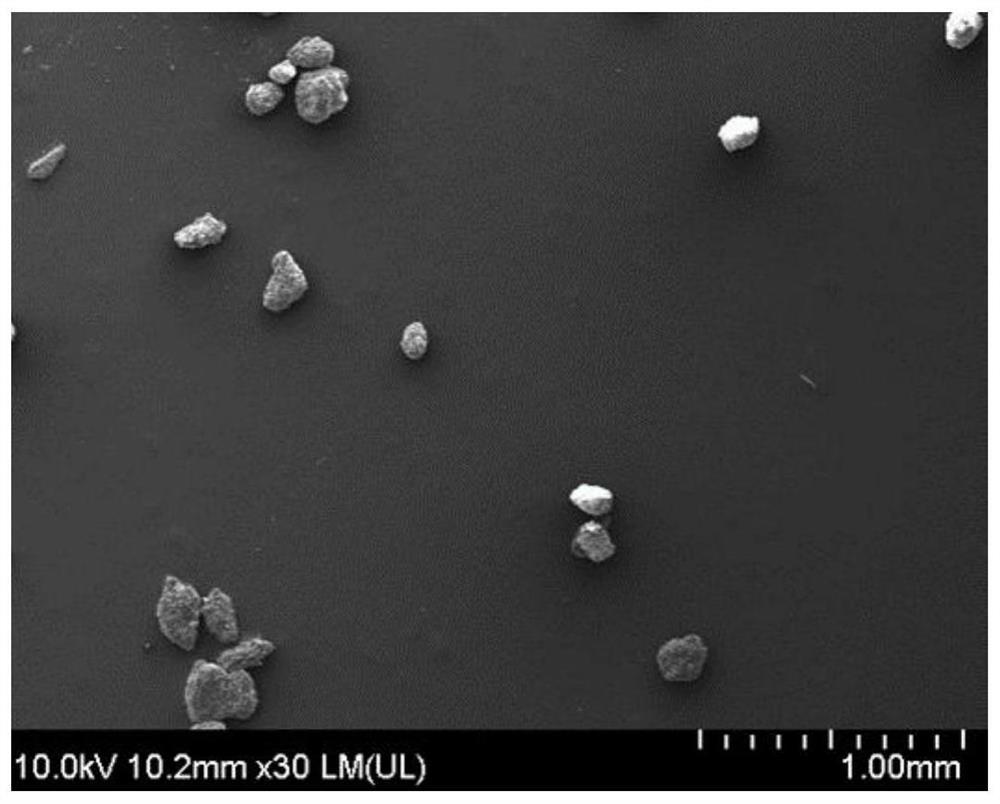

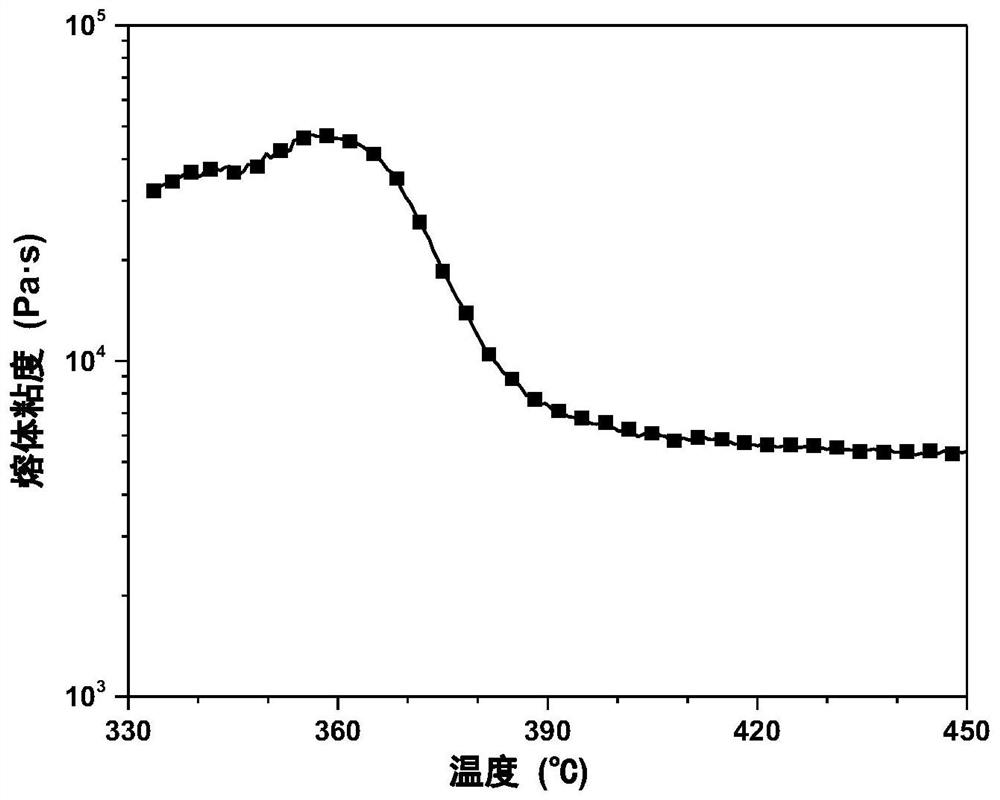

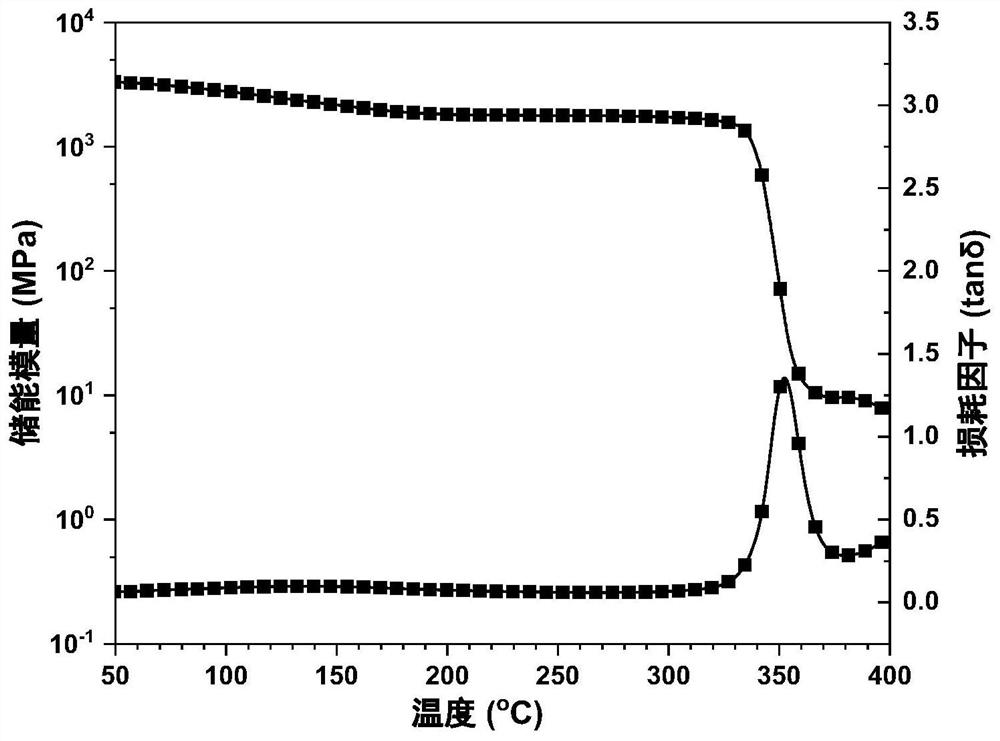

Embodiment 1

[0046] Under nitrogen protection, 189.25g (1.75mol) of m-phenylenediamine (m-PDA), 240.17g (0.75mol) of 4,4'-diamino-2 , 2'-bistrifluoromethylbiphenyl (TFDB) and 4138.07g of N-methylpyrrolidone (NMP), stirred until the diamine was completely dissolved to obtain a homogeneous solution. Then add 1088.39g (2.45mol) of 4,4'-(hexafluoroisopropylidene) diphthalic anhydride (6FDA) into the homogeneous solution of mixed diamines, and stir the reaction at room temperature until the solution is clear , add the phthalic anhydride (PA) of 14.81g (0.10mol) and the N-methylpyrrolidone (NMP) of 459.79g, obtain the polyamic acid that solid content is 25wt.% after continuing stirring reaction at room temperature for 6 hours resin solution. Add 2476.13g of acetic anhydride and 997.23g of pyridine into the above polyamic acid resin solution, and continue stirring for 14h to carry out chemical imidization reaction to prepare a polyimide resin solution. Transfer the polyimide solution to a plast...

Embodiment 2

[0049] Under nitrogen protection, 162.21g (1.50mol) of m-phenylenediamine (m-PDA) and 264.21g (1.50mol) of 3,5-diaminotrifluorotoluene were sequentially added to a reaction vessel equipped with mechanical stirring and a thermometer (35DBTF) and 3687.98g of N,N-dimethylacetamide (DMAc), stirred until the diamine was completely dissolved to obtain a homogeneous solution. Then add 1319.39g (2.97mol) of 4,4'-(hexafluoroisopropylidene) diphthalic anhydride (6FDA) into the homogeneous solution of mixed diamines, and stir the reaction at room temperature until the solution is clear , Add 10.37g (0.07mol) of phthalic anhydride (PA) and 409.77g of N,N-dimethylacetamide (DMAc) and continue to stir the reaction at room temperature for 8 hours to obtain a solid content of 30wt.%. Polyamic acid resin solution. 1531.35 g of acetic anhydride and 700.81 g of pyridine were added to the above polyamic acid resin solution, and the stirring was continued for 8 hours to carry out chemical imidiza...

Embodiment 3

[0052] Under nitrogen protection, 162.21g (1.50mol) of m-phenylenediamine (m-PDA) and 264.21g (1.50mol) of 2,5-diaminotrifluorotoluene were sequentially added to a reaction vessel equipped with mechanical stirring and a thermometer (25DBTF) and 3663.15g of N-methylpyrrolidone (NMP), stirred until the diamine was completely dissolved to obtain a homogeneous solution. Then add 1288.30g (2.90mol) of 4,4'-(hexafluoroisopropylidene) diphthalic anhydride (6FDA) into the homogeneous solution of mixed diamines, and stir the reaction at room temperature until the solution is clear , add the phthalic anhydride (PA) of 29.62g (0.20mol) and the N-methylpyrrolidone (NMP) of 406.85g, obtain the polyamic acid that solid content is 30wt.% after continuing stirring reaction at room temperature for 4 hours resin solution. Add 1531.35g of acetic anhydride and 597.93g of pyridine into the above polyamic acid resin solution, and continue to stir for 12h to carry out chemical imidization reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com